Platinum-based catalyst carrier of direct methanol fuel cell and preparation method thereof

A methanol fuel cell and catalyst carrier technology, which is applied in the field of materials, can solve the problems of difficult catalyst activity stability, unstable catalytic performance, reduced catalytic activity, etc., and achieves the advantages of reducing noble metal loading, simple and feasible preparation method, and improved catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode 1: In this implementation mode, graphite-like carbon nitride / carbon composite carrier material is prepared according to the following steps:

[0026] Weigh 200mg of XC-72 carbon black and 500mg of urea, add 20mL of absolute ethanol to it, and ultrasonically disperse for 1 hour to obtain a black slurry, then dry it at 70°C, put it in a porcelain boat after grinding, and wrap it with copper foil , put the porcelain boat into the nitrogen atmosphere of the tube furnace, at 10℃min -1 The heating rate was raised to 550°C and kept for 2 hours, after being cooled to room temperature, it was washed with ultrapure water and dried in vacuum at 70°C to obtain a graphite-like carbon nitride / carbon composite carrier material, in which the graphite-like carbon nitride material accounted for the carrier The mass fraction is 5%.

specific Embodiment approach 2

[0027] Specific implementation mode 2: In this implementation mode, graphite-like carbon nitride / carbon composite carrier material is prepared according to the following steps:

[0028] Weigh 200mg of carbon nanotubes and 500mg of thiourea, add 20mL of absolute ethanol to it, and ultrasonically disperse for 1 hour to obtain a black slurry, then dry it at 70°C, put it in a porcelain boat after grinding, and wrap it with copper foil. Porcelain boats are placed in a nitrogen atmosphere of a tube furnace, heated to 600°C at a heating rate of 10°C min- and kept for 1 hour. After cooling to room temperature, they are washed with ultrapure water and dried in vacuum at 70°C to obtain graphite-like nitriding A carbon / carbon composite carrier material, wherein the graphite-like carbon nitride material accounts for 20% of the mass fraction of the carrier.

specific Embodiment approach 3

[0029] Specific implementation mode three: In this implementation mode, graphite-like carbon nitride / carbon composite carrier material is prepared according to the following steps:

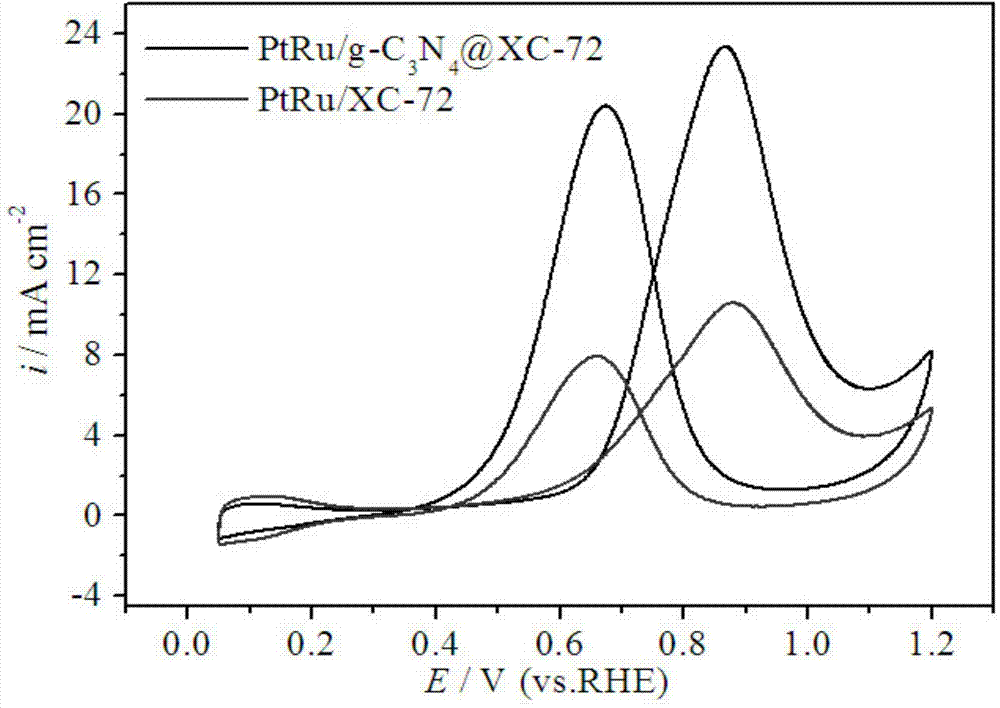

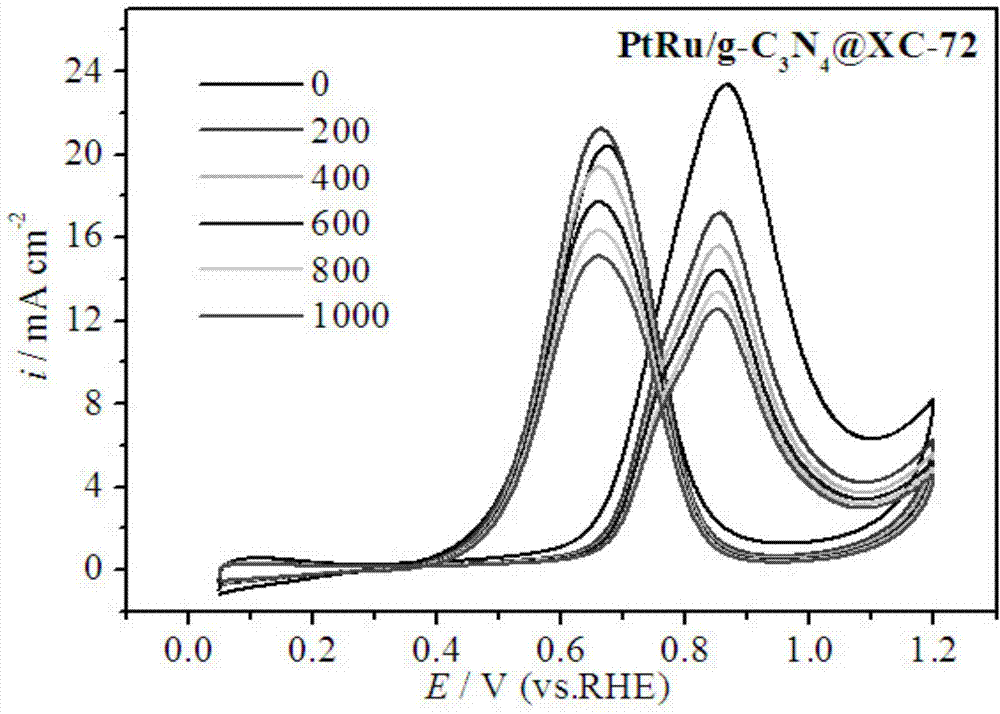

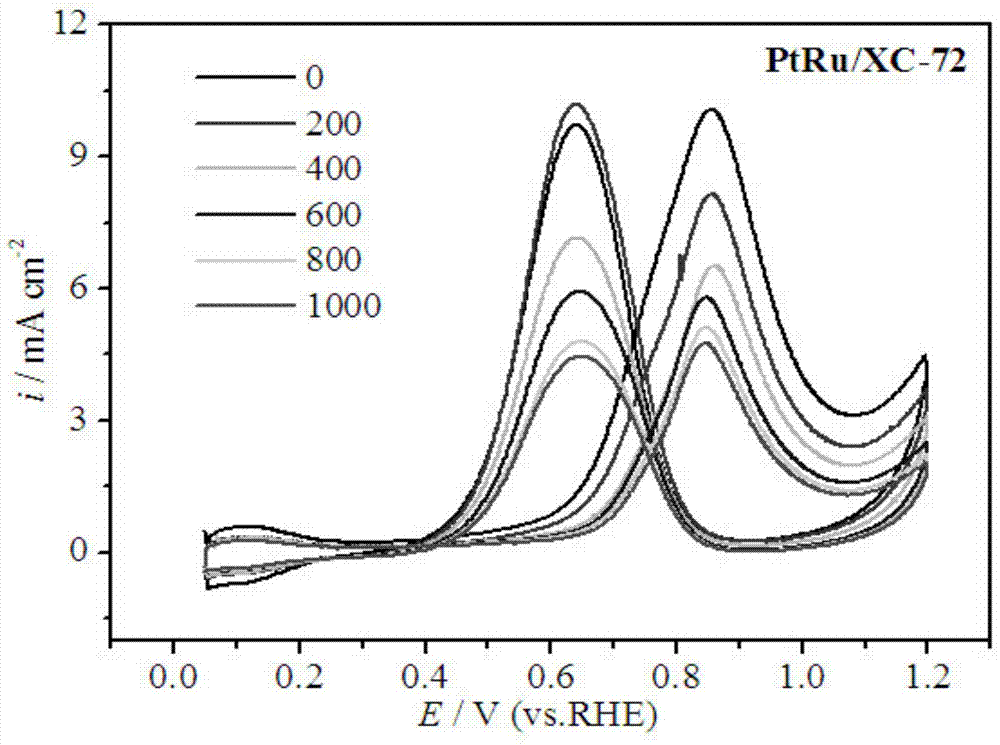

[0030] Weigh 200mg of XC-72 carbon black and 500mg of urea, add 20mL of absolute ethanol to it, and ultrasonically disperse for 1 hour to obtain a black slurry, then dry it at 70°C, put it in a glass tube with one end sealed after grinding, and then Sinter the open end into a capillary opening through heat treatment, put it into a tube furnace in a nitrogen atmosphere, and heat it at 8°C min -1 The temperature was raised to 650°C at the heating rate and kept for 2 hours. After cooling to room temperature, it was washed with ultrapure water and dried in vacuum at 70°C to obtain a graphite-like carbon nitride / carbon composite carrier material, in which the graphite-like carbon nitride material accounted for the carrier The mass fraction is 5%, and its performance test results are as follows Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com