Portable solar cell module and manufacturing method thereof

A technology of solar cell components and solar cells, applied in semiconductor/solid-state device manufacturing, electrical components, final product manufacturing, etc., can solve the problems of producing solar cell components, low production efficiency, complicated process, etc., and achieve simple and reliable process Improve operation and production efficiency, and improve the effect of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The substantive features of the present invention will be further described in conjunction with the accompanying drawings.

[0046] A portable solar cell assembly, characterized in that:

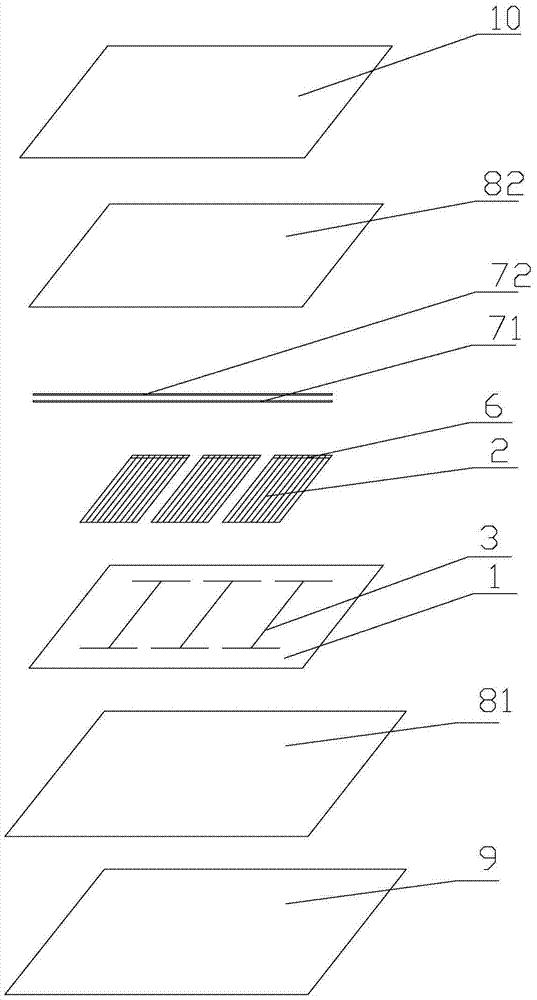

[0047] Such as figure 1 Shown:

[0048] 1) On the base layer (1) there is an "I" character positioning frame (3) adapted to the outer dimensions of the solar cell (2), and the width of the "I" character positioning frame (3) is the same as that of the solar cell (2) , the height of the "工" character positioning frame (3) is the same as the height of the light-receiving area of the solar cell (2);

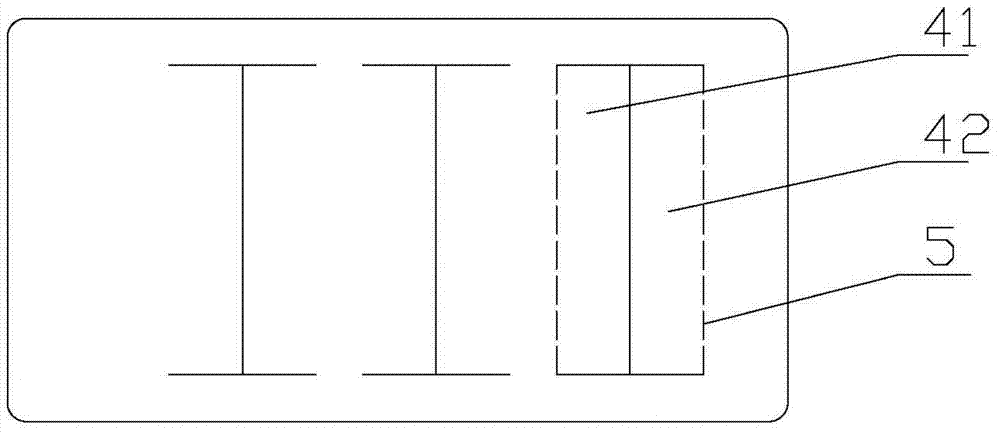

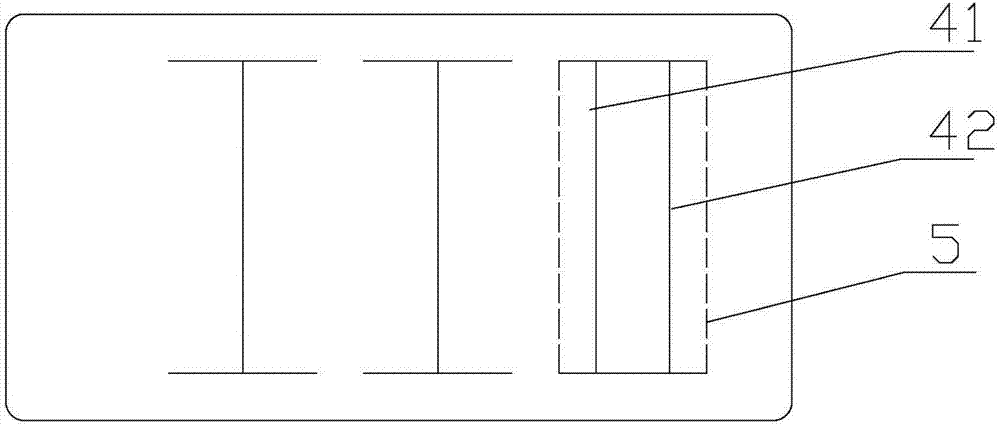

[0049] Such as figure 2 , image 3 Shown:

[0050] 2) The "工" character positioning frame (3) has a left tongue (41) and a right tongue (42), which can form a rectangular light-receiving window (5) after being turned up;

[0051] Such as figure 1 Shown:

[0052] 3) There are flexible connecting wires (71) and (72) on the base layer (1) and the solar cell (2) to connect the solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com