Organic light-emitting diode display panel and forming method thereof

A technology for light-emitting diodes and display panels, which is applied to instruments, electrical components, and electrical solid-state devices, etc., can solve the problems of aggravating the color shift phenomenon of display panels, the color shift of organic light-emitting diode display panels, and different resonance wavelengths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

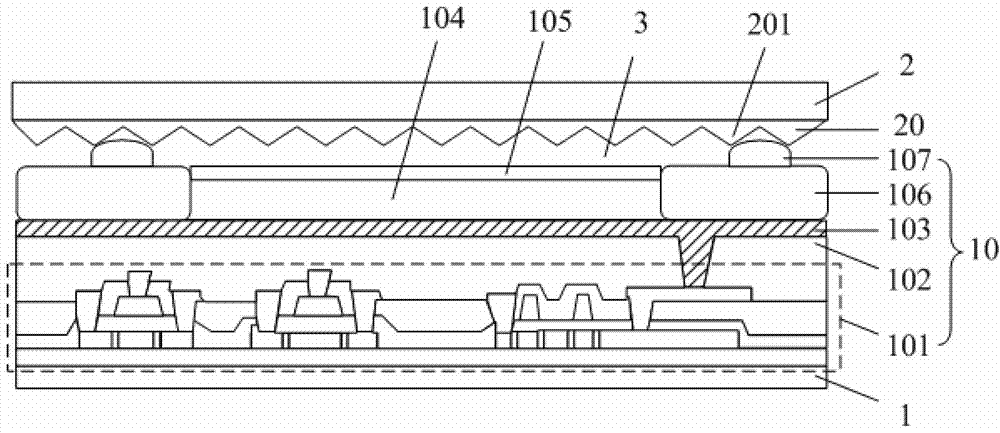

[0027] Embodiment 1 of the present invention provides an OLED display panel, please refer to figure 1 .

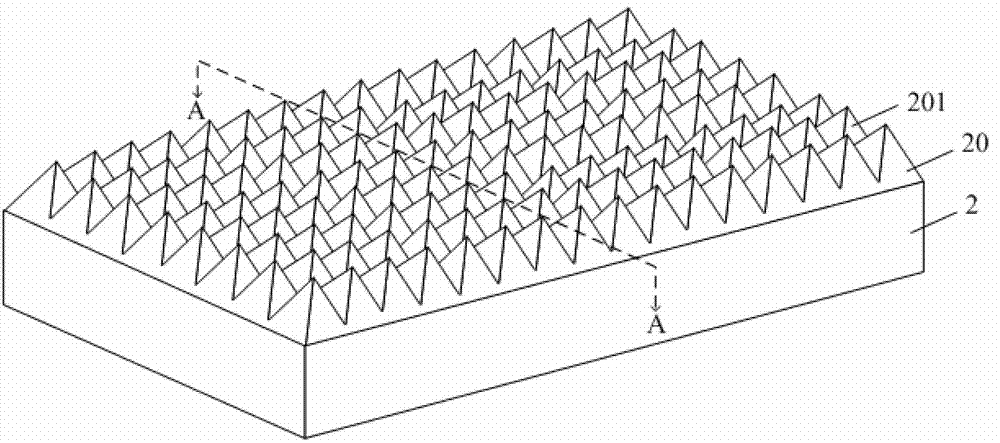

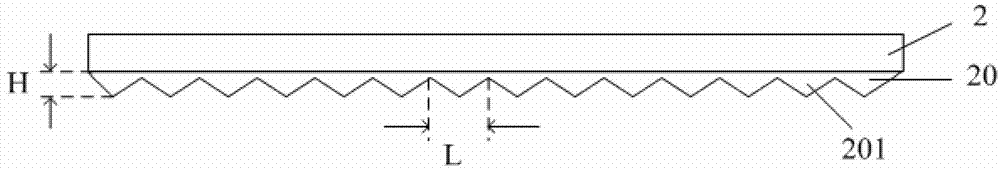

[0028] The organic light emitting diode display panel includes a base substrate 1 and an encapsulation cover plate 2 which are oppositely arranged. The inner surface of the base substrate 1 includes an organic light emitting diode 10 , that is, the organic light emitting diode 10 is located between the base substrate 1 and the package cover 2 . The inner surface of the package cover 2 includes a light-scattering film layer 20 , that is, the light-scattering film layer 20 is located between the package cover 2 and the OLED 10 .

[0029] The organic light emitting diode 10 includes an active electrode part 101 , a protective layer 102 , a reflective electrode layer 103 , an organic light emitting layer 104 , a transparent electrode layer 105 , a pixel defining part 106 and a spacer 107 .

[0030] The active electrode part 101 is located on the inner surface of the base sub...

Embodiment 2

[0051] Embodiment 2 of the present invention provides another organic light emitting diode display panel, please refer to Figure 4 .

[0052] The organic light emitting diode includes a base substrate 4 and a package cover 5 that are oppositely arranged. The inner surface of the base substrate 4 includes an organic light emitting diode 40 , and the inner surface of the package cover 5 includes a light scattering film layer 50 . The organic light emitting diode 40 includes a reflective electrode layer 401 located on the inner surface of the substrate 4, an organic light-emitting layer 402 located on the surface of the reflective electrode layer 401, a transparent electrode layer 403 located on the surface of the organic light-emitting layer 402, and an organic light-emitting layer 403 located on the surface of the transparent electrode layer 403. The passivation protection layer 404, wherein the light generated by the organic light-emitting layer 402 is transmitted through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com