Anti-seepage stop valve

A cut-off valve and anti-leakage technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of easy leakage and waste of water resources at the joint between the valve core and the valve stem, and achieve simple and reasonable structure and easy installation And the effect of easy disassembly and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

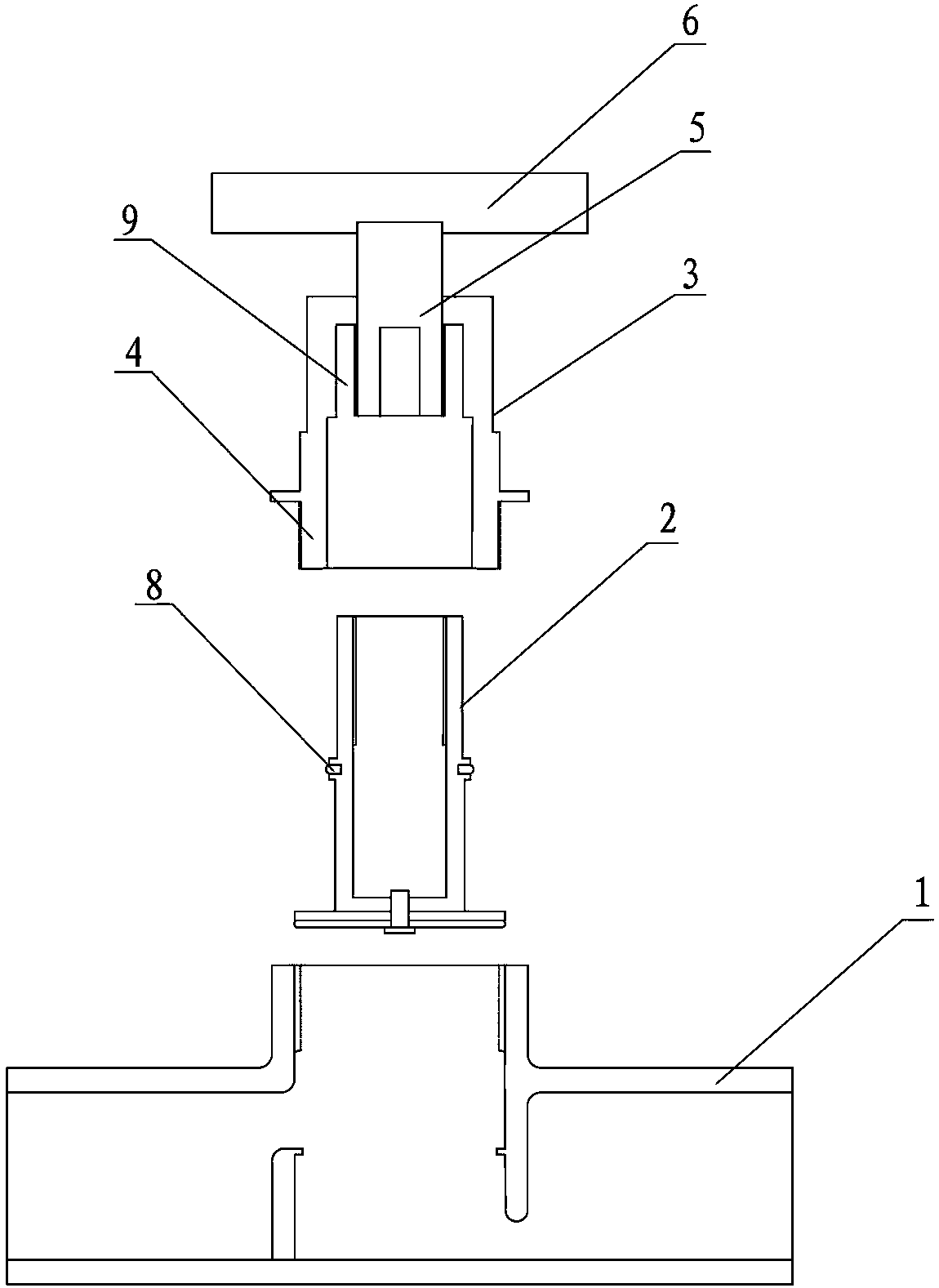

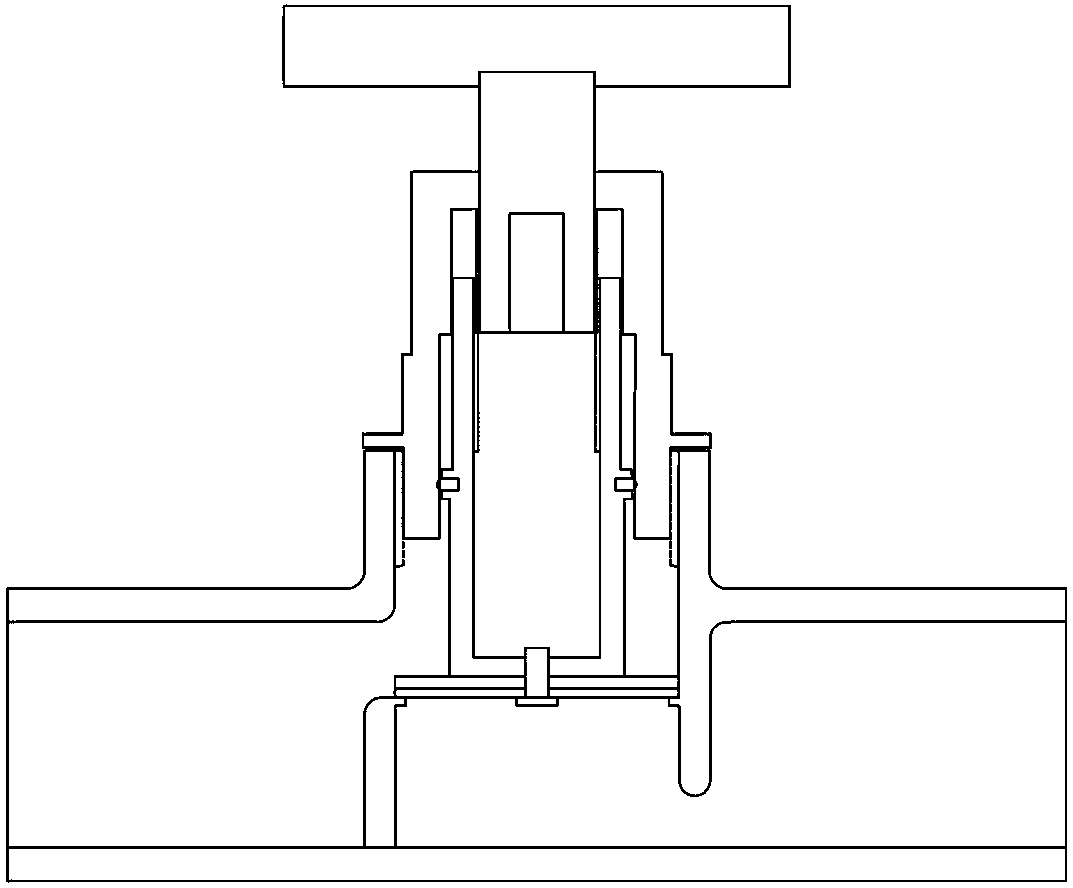

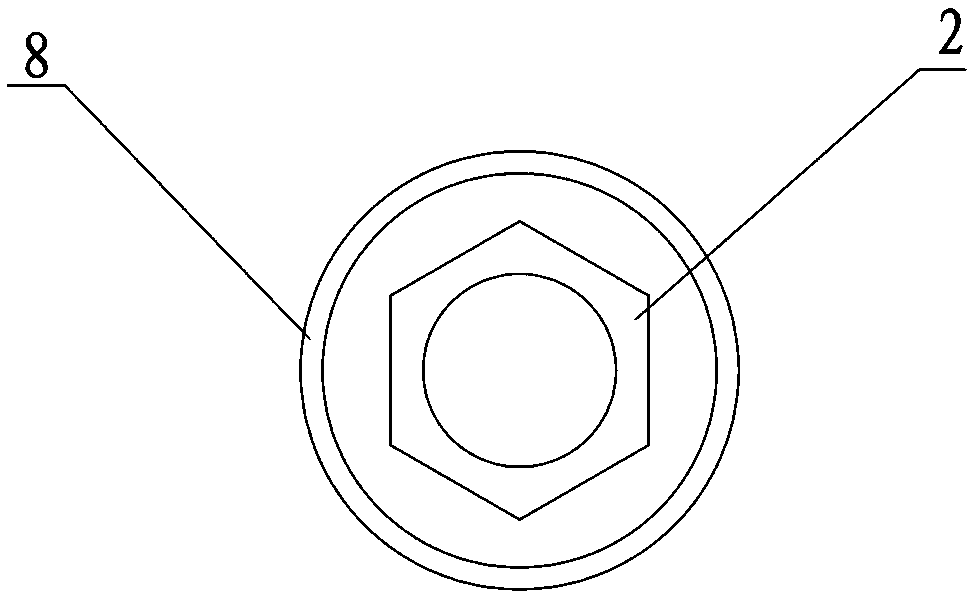

[0012] Refer to 1 and 2, an anti-leakage stop valve, including a valve body 1, a valve core 2 and a valve stem 3, the lower part of the valve stem 3 is connected to the upper part of the valve core 2 through threads, and the center of the upper end surface of the valve core 2 is provided with an axial thread Blind hole; the lower part of the valve stem 3 is provided with a sleeve 4, and the outer surface of the sleeve 4 is provided with threads for connecting with the valve body 1; The rotary handle 6 is connected, and the lower part of the screw rod 5 is used to spirally cooperate with the axial threaded hole on the valve core 2; the outer surface of the valve core 2 is provided with an annular rib 7, and at least one annular rib 7 is provided on the outer surface of the annular rib 7. Groove, a sealing ring 8 is placed in the annular groove, which is used to form a water seal between the valve core 2 and the inner wall of the valve stem sleeve 4 . The effect of sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com