Self-priming non-clogging sewage pump

A non-clogging, sewage pump technology, applied in the direction of pumps, drive pumps, non-variable pumps, etc., can solve the problems of restricting the application of sewage pumps, self-priming performance dependence, and large project investment, so as to shorten the self-priming time and manufacture The effect of low cost and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

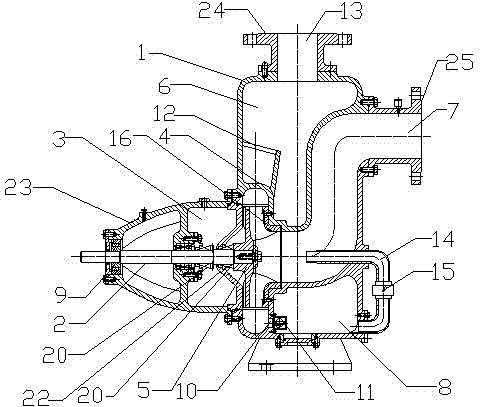

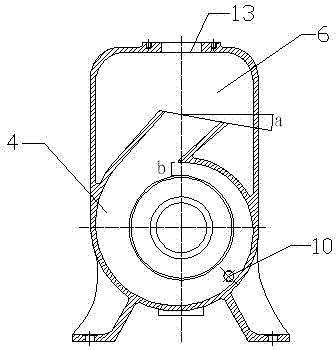

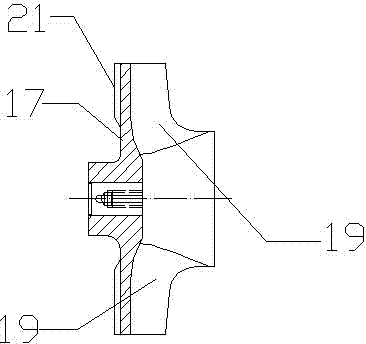

[0018] like figure 1 and figure 2 As shown, a self-priming non-clogging sewage pump includes a pump body 1, a rotating shaft 2, an impeller 5, a pump cover 22 and a suspension 23, and the pump body 1 includes an oil chamber 3, a volute 4, a gas-liquid separation chamber 6, an inlet The water pipe 7, the liquid storage chamber 8 and the front cover 16, the pump cover 22 is arranged on the left side of the volute 4, the suspension 23 is fixed on the left end of the pump body 1, one end of the rotating shaft 2 is connected with the impeller 5, and the other end runs through the pump cover 22, The oil chamber 3 and the suspension 23 are connected with the bearing 9 at the left end of the suspension 23, the impeller 5 is arranged inside the volute 4, and the right side of the lower end of the volute 4 is provided with a backflow hole 10, and the backflow hole 10 passes through the one-way water inlet valve 11 Connected with the liquid storage chamber 8, the outlet 12 at the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com