Heat energy power equipment and work doing method thereof

A technology of power equipment and thermal energy, which is applied in the direction of mechanical equipment, hot gas variable displacement engine devices, machines/engines, etc., can solve the problems of high manufacturing cost and high cost, and achieve the effects of reducing energy loss, low noise, and simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

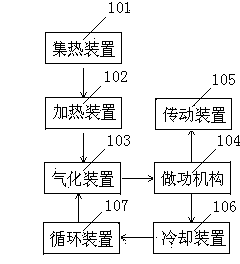

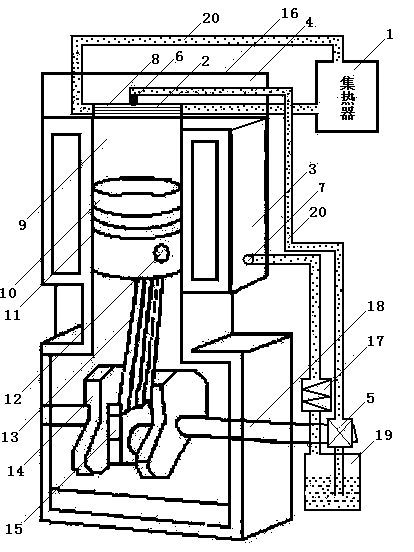

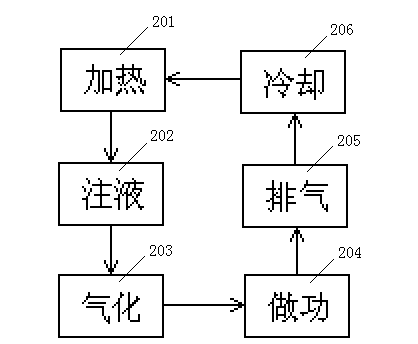

[0038] Refer to attached Figure 1-3 , the embodiment of the present invention is:

[0039]A kind of thermal power equipment, which consists of a heat collector 1, a gasification heat conducting sheet 2, an insulation layer 3, a cylinder head 4, a pressure pump 5, an atomizer 6, an automatic exhaust hole 7, a gasification reactor 8, a cylinder 9, Piston 10, piston ring 11, connecting pin 12, connecting rod 13, crankshaft 14, bearing 15, casing 16, cooler 17, transmission shaft 18, liquid storage tank 19 and pipeline 20, and cylinder 9 is provided with piston 10 , the piston 10 is provided with a piston ring 11, the piston 10 is connected to the connecting rod 13 through the connecting pin 12, the connecting rod 13 is connected to the crankshaft 14, the crankshaft 14 is provided with a bearing 15, the bearing 15 is fixed on the transmission shaft 18, and the transmission shaft 18 is fixed on the transmission shaft through the bearing On the casing 16, one end of the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com