Cyanobacteria cell crushing method and device

A crushing method and technology of cyanobacteria, applied in the direction of microorganism-based methods, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of unsatisfactory cyanobacteria cell crushing effect, low cell crushing rate, time-consuming, etc., and achieve improvement Research and development efficiency and cyanobacteria natural product production efficiency, the effect of efficient methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

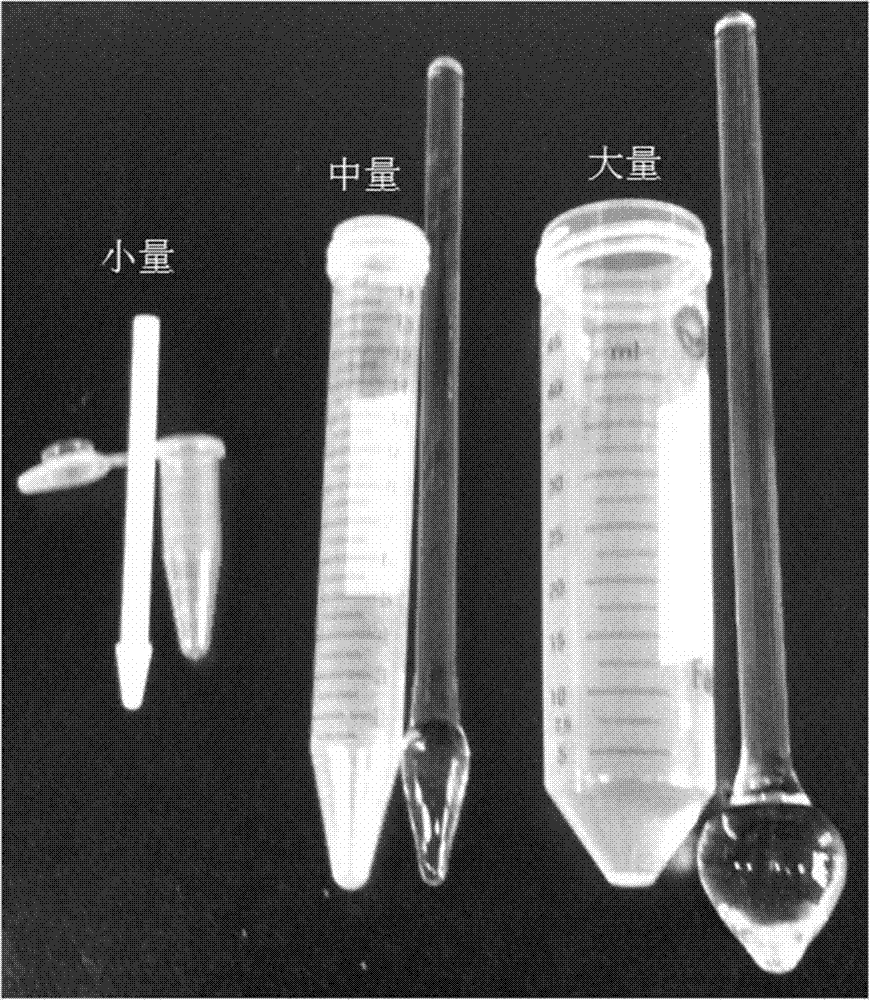

[0054] Embodiment 1, the device of emery grinding method broken cyanobacteria cell

[0055] The emery grinding method involved in the present invention breaks the device of cyanobacteria cell, can be any one of following (I)-(III) ( figure 1 ):

[0056] (1) A device consisting of a 1.5mL centrifuge tube and a matching grinding rod 1.

[0057] (II) A device consisting of a 50mL conical bottom centrifuge tube and a matching grinding rod 2 .

[0058] (III) A device consisting of a 15mL conical centrifuge tube and matching grinding rods 3 .

[0059] Wherein, the 1.5mL centrifuge tube is a product of Sangon Bioengineering Co., Ltd., and its catalog number is ST620-1; the 50mL conical bottom centrifuge tube is a product of Axygen Company, and its catalog number is SCT-50ML-25-S The 15mL conical bottom centrifuge tube is a product of Axygen Company, and its catalog number is SCT-15ML-25-S. The grinding rod 1 is a product of KimbleChase Company in the United States, and its catalo...

Embodiment 2

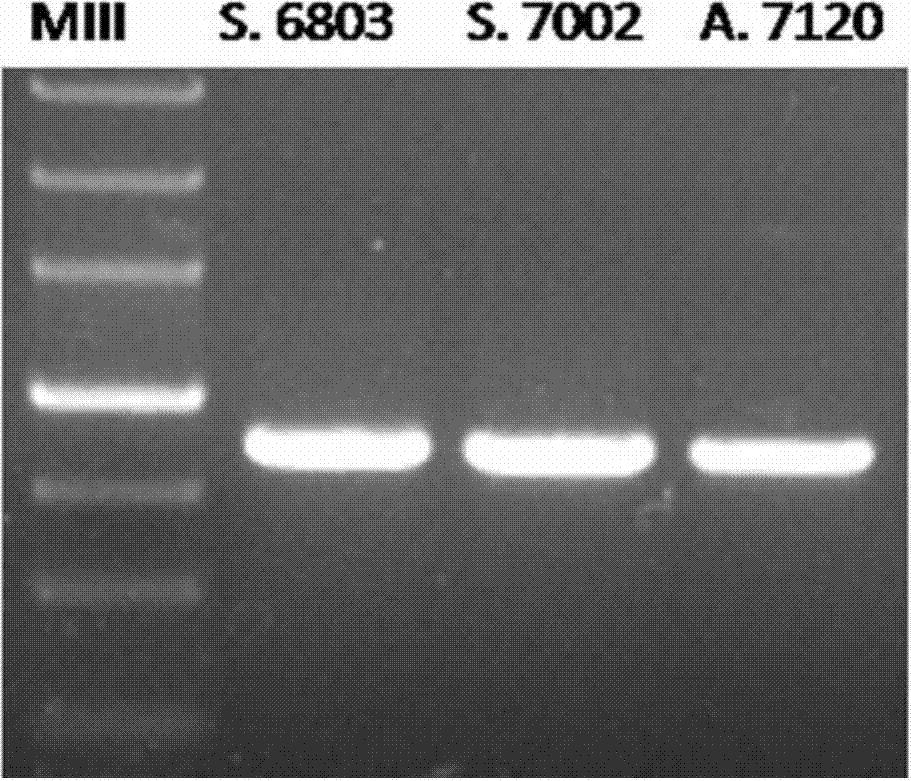

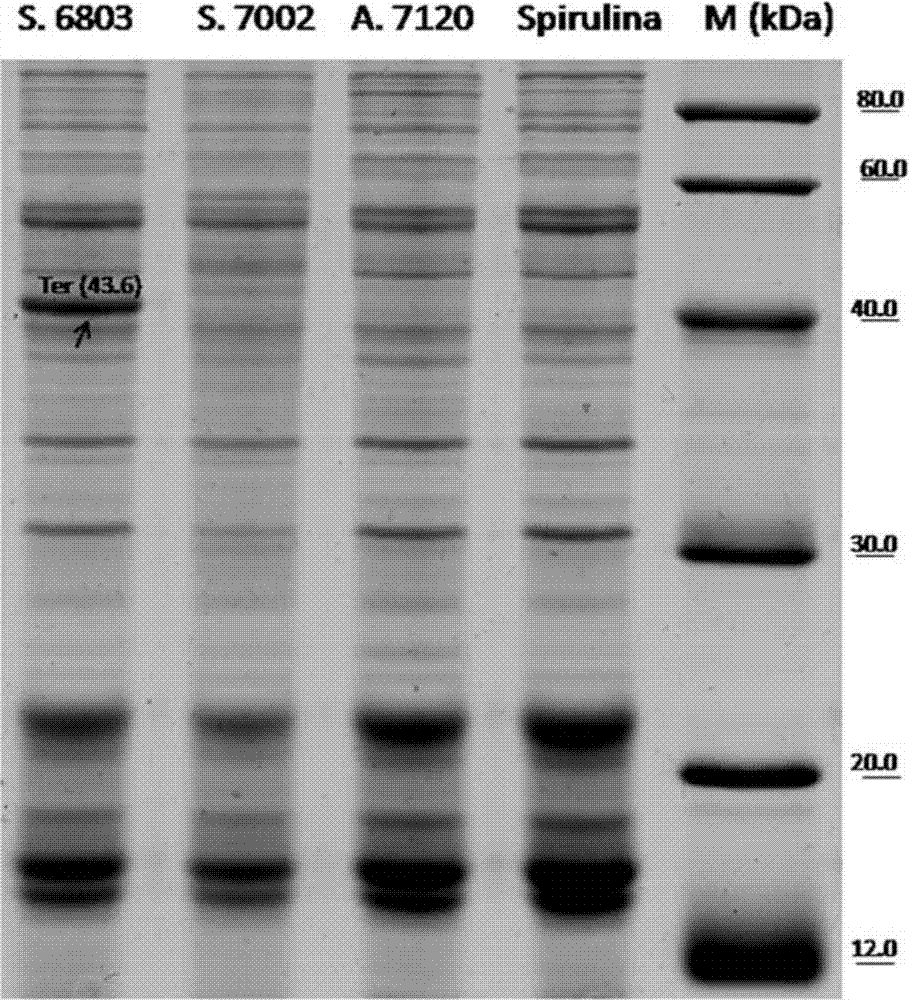

[0062] Embodiment 2, carborundum grinding method is used for crushing a small amount of freshwater single-cell cyanobacteria Synechocystis 6803

[0063] In this example, the freshwater unicellular cyanobacterium Synechocystis 6803 was crushed in a small amount by using the device in (I) of Example 1. details as follows:

[0064] 1. Preparation of algae liquid of freshwater unicellular cyanobacterium Synechocystis 6803

[0065] Scrape multiple algae colonies from the plate of freshwater cyanobacterium Synechocystis PCC6803 and inoculate them into BG-11 liquid medium; -2 .s -1 cultured to logarithmic phase (OD 730 For 3), standby.

[0066] 2. Emery grinding method to crush the freshwater single-celled cyanobacteria Synechocystis 6803

[0067] Take 1ml of the freshwater unicellular cyanobacterium Synechocystis 6803 obtained in step 1, add it to a 1.5ml centrifuge tube, centrifuge at 12000rpm (equivalent to 13000g), 4°C for 2min, discard the supernatant, collect the cells, a...

Embodiment 3

[0100] Embodiment 3, emery grinding method is used for crushing a small amount of seawater single-cell cyanobacterium Synechococcus 7002

[0101] In the present embodiment, adopt the device in (1) among the embodiment 1 to carry out a small amount of crushing to seawater unicellular cyanobacterium Synechococcus 7002. details as follows:

[0102] 1. Preparation of seawater unicellular cyanobacterium Synechococcus 7002 algae liquid

[0103] Referring to step 1 of Example 2, replace the freshwater unicellular cyanobacteria Synechocystis 6803 with the seawater unicellular cyanobacterium Synechococcus 7002.

[0104] 2. Emery grinding method to crush single-cell cyanobacteria Synechococcus 7002 in seawater

[0105] Refer to step 2 of Example 2, and replace the freshwater unicellular cyanobacteria Synechocystis 6803 with the seawater unicellular cyanobacterium Synechococcus 7002.

[0106] 3. Detection of the crushing effect of single-celled cyanobacteria Synechococcus 7002 in sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com