Molten nano-carbonate heat transfer and accumulation medium, and preparation method and application thereof

A heat storage medium and carbonate molten salt technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as pipeline blockage and maintenance costs, achieve large phase change latent heat, widen the working temperature range, heat absorption and Good heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

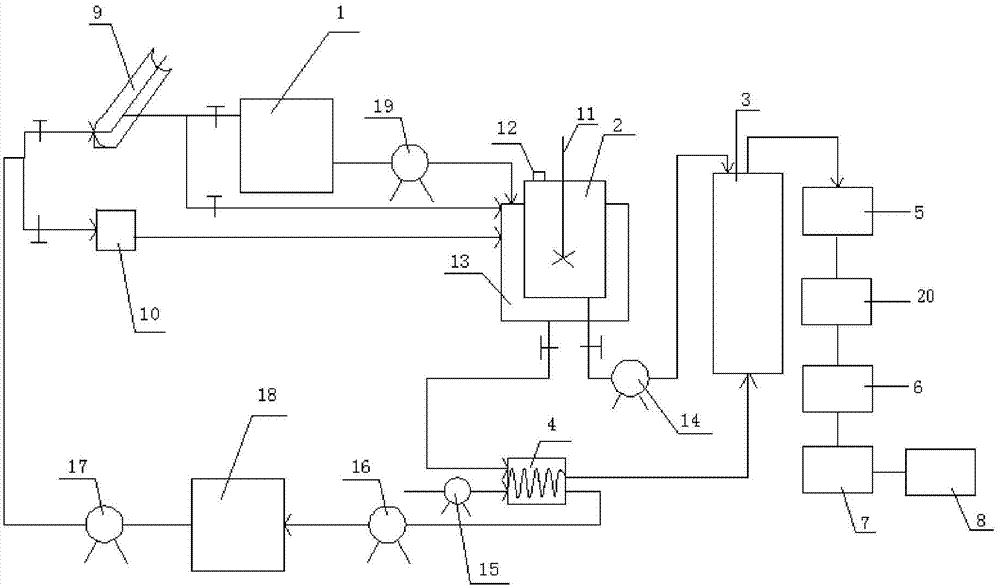

[0056] The preparation method of the carbonic acid nano molten salt heat transfer heat storage medium of the present invention is as follows:

[0057] 1) Preparation of metal oxide nanoparticles MgO and / or non-metal oxide nanoparticles SiO by gas phase method 2 (Note that the nanoparticles in this step can be obtained commercially, and the commercially obtained nanoparticles can also achieve the purpose of the present invention);

[0058] 2) Mix sodium chloride and lithium carbonate evenly and add them to the molten salt tank from the feeding port, open the valve between the interlayer and the solar heat collection system to let the heat carrier heated by the solar heat collection system flow to the interlayer and statically heat it into the molten salt tank The solids are all melted, kept for 10-30 minutes, naturally cooled to room temperature and crushed mechanically;

[0059] Then add potassium carbonate and sodium carbonate to the molten salt tank, stir to mix evenly to o...

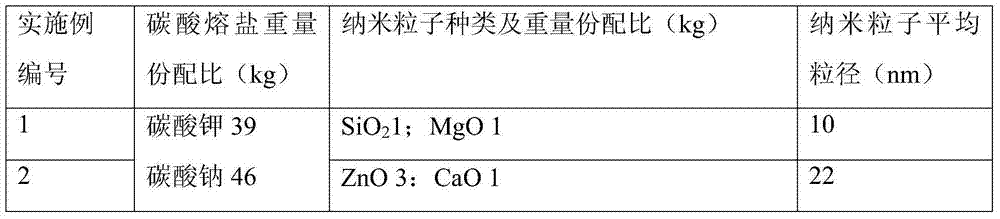

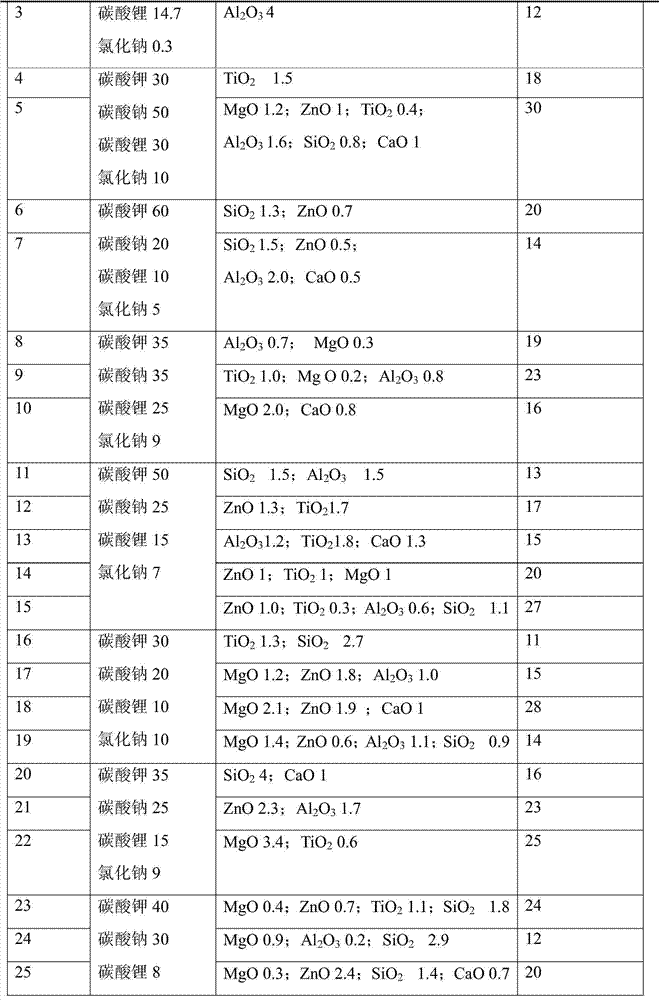

Embodiment 1~25

[0065] Examples 1-25 were all obtained according to the above-mentioned preparation method. Table 1 shows the formulations of various examples of the present invention and the particle sizes of nanoparticles in the formulations, as well as the formulation (X1) of carbonate molten salts according to the prior art. Among them, the Chinese invention patent with application number 200910037348.7 discloses a lithium-containing carbonate molten salt Salt heat transfer heat storage medium and its preparation method, X1 is lithium-containing carbonate molten salt (without nanoparticles) obtained by the inventor according to the formula and preparation method described in Example 4 of the specification;

[0066] Table 1. Formula of carbonate nano molten salt and particle size of corresponding nanoparticles

[0067]

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com