Compound Plastic Additives

A technology of additives and plastics, which is applied in the formulation and preparation of high-grade composite plastic additives, can solve the problems of increased quality risk, large difference in performance of metal fatty carboxylate, etc., and achieves easy processing, excellent comprehensive performance, and realization of profit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

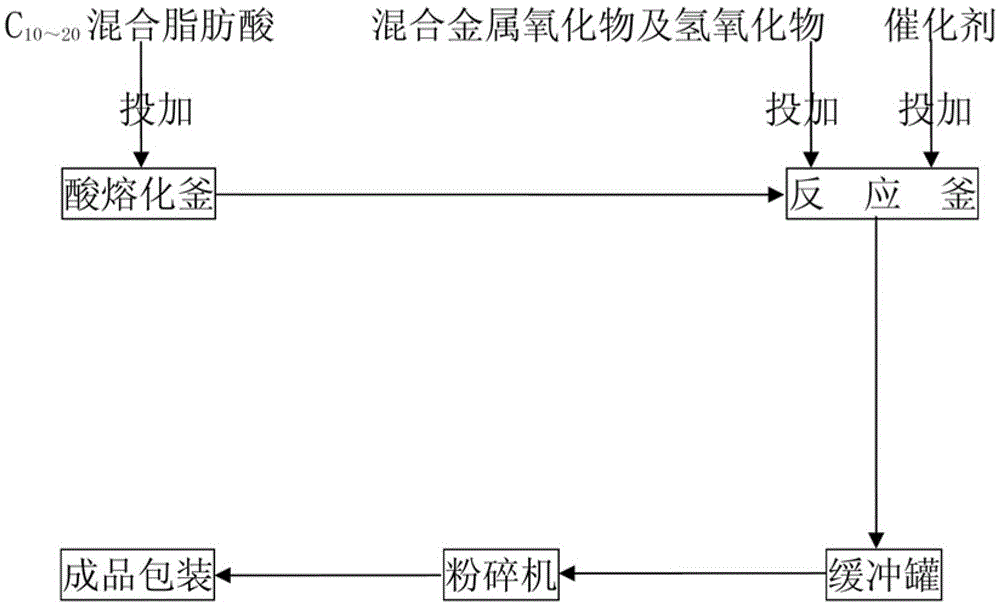

[0018] Specific implementation mode one: see figure 1 , The composition and weight percentages of this specific implementation are: 8% metal oxide, 78% C10-20 mixed fatty acid, and 0.5% catalyst.

[0019] The metal oxides are zinc oxide and calcium hydroxide, and the weight percentages of zinc oxide and calcium hydroxide are: 15%-40%: 60%-85%.

[0020] Its preparation process is:

[0021] 1. Acid melting process: In a container with a certain capacity, add an appropriate amount of C10-20 mixed fatty acids, slowly increase the temperature at normal pressure to melt, control the temperature at 70°C-90°C, start stirring slowly, C10-20 mixed fatty acids Melt slowly until completely melted before proceeding to the next step.

[0022] 2. Chemical synthesis process: transfer the molten C10-20 mixed fatty acid to the reaction kettle, slowly add the metal oxide and hydroxide in a good proportion, then slowly add a certain amount of catalyst, cover it to seal it, Then slowly raise th...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that its composition and weight percentage are respectively: 10% metal oxide, 85% C10-20 mixed fatty acid, 0.8% catalyst, and its preparation method is the same as The specific embodiment one is the same.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 in that its composition and weight percentage are: 12% metal oxide, 87% C10-20 mixed fatty acid, and 1% catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com