A strip steel surface oxide removal method with low acid consumption and high surface quality

A surface oxide and high surface technology, which is applied in the field of deep processing of ordinary hot-rolled flat products, can solve problems such as the surface quality of strip steel that cannot meet the use requirements and uneven reaction, and achieve shortening of acid reaction time, short pickling time, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

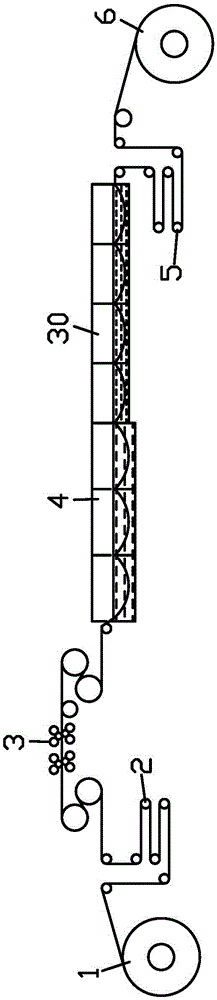

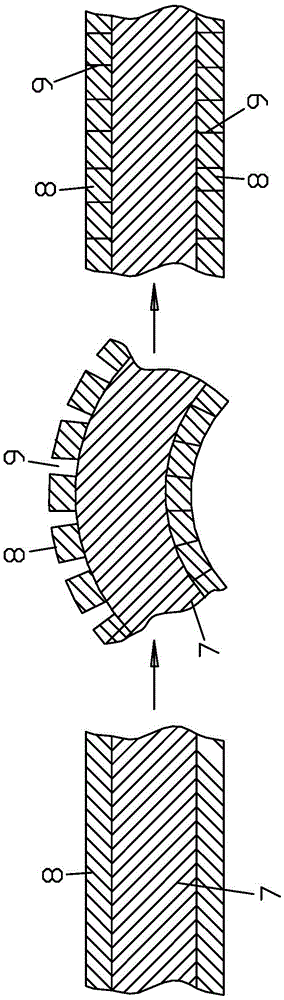

[0039] Such as Figure 7 and Figure 8 Shown, the present invention relates to a kind of low acid consumption high surface quality band steel surface oxide removal method, described oxide comprises Fe 2 o 3 31. Fe 3 o 4 32. FeO33, specifically comprising the following steps:

[0040] A. Uncoiler 1 uncoils;

[0041] B. The tempering machine 11 crushes and peels off the oxide 8 on the surface of the steel strip 7;

[0042] C. The multi-roller straightener 12 further breaks and peels off the oxide 8 on the surface of the strip 7;

[0043] D. the scrubbing roller 16 in the scrubbing device 15 removes the oxide 8 that comes off and loosens on the surface of the strip steel 7;

[0044] E. Pickling 4 and rinsing 30 the strip steel 7 after smoothing, straightening and scrubbing;

[0045] F. enter the mechanical grinding device 17 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com