Method for judging freeze drying precooling temperatures of tobacco leaf samples by aid of eutectic crystal points and eutectic melting points

A technology of eutectic point and eutectic point, which is applied in the direction of drying solid materials, drying solid materials without heating, tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

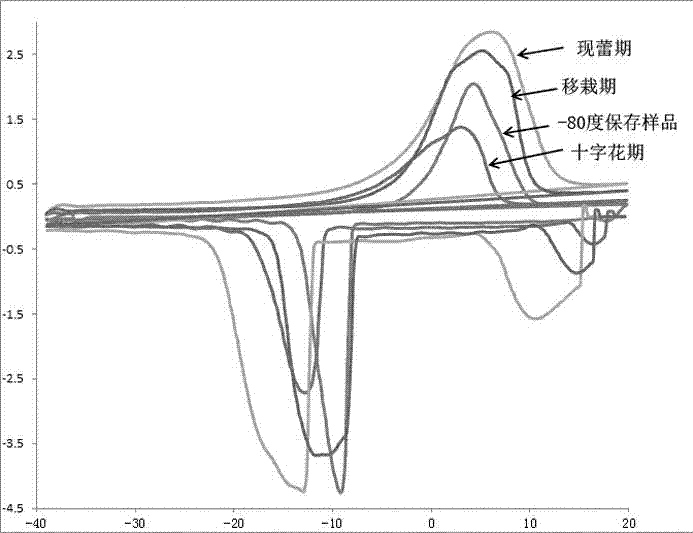

[0019] Samples of fresh tobacco leaves at different stages (cross-flowering stage, transplanting stage, budding stage) and tobacco leaves stored at -80°C were taken, and their heat flow curves were measured by differential scanning calorimetry. figure 1 Shown are the DSC heat flow curves of cruciferous tobacco leaves and tobacco leaves stored at -80°C. The eutectic points and eutectic points of the four samples are shown in Table 1. In order to save energy and improve drying efficiency, combined with the eutectic point and eutectic point of different fresh tobacco leaves, the primary drying temperature (or eutectic drying temperature) of tobacco samples was set at -20°C, and the secondary drying temperature (or eutectic drying temperature) was set at -20°C. drying temperature) is 0°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com