Composite busbar insulation supporting device and IGBT power module

A technology of insulating support and composite busbar, which is applied in the field of converters, can solve the problems of composite busbar deformation and poor electrical safety of IGBT power modules, and achieve the effect of avoiding deformation and improving electrical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

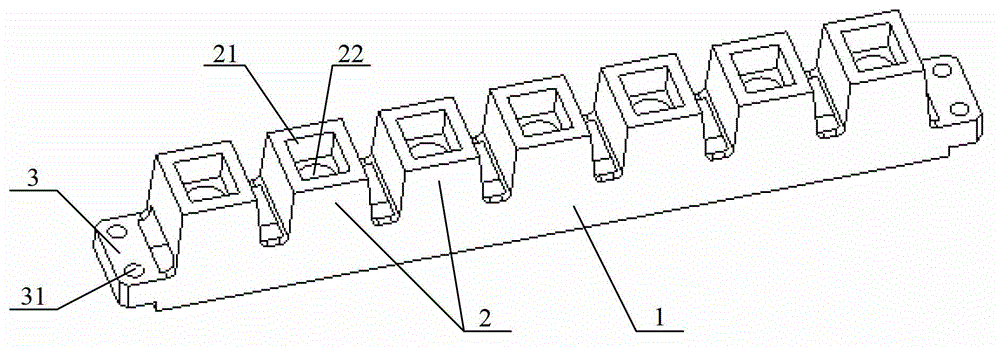

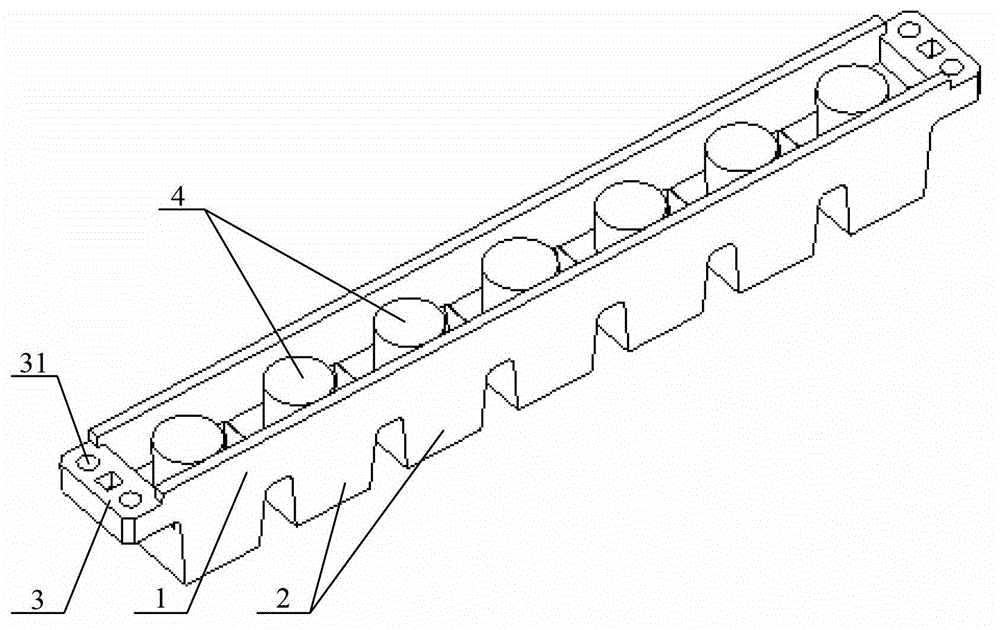

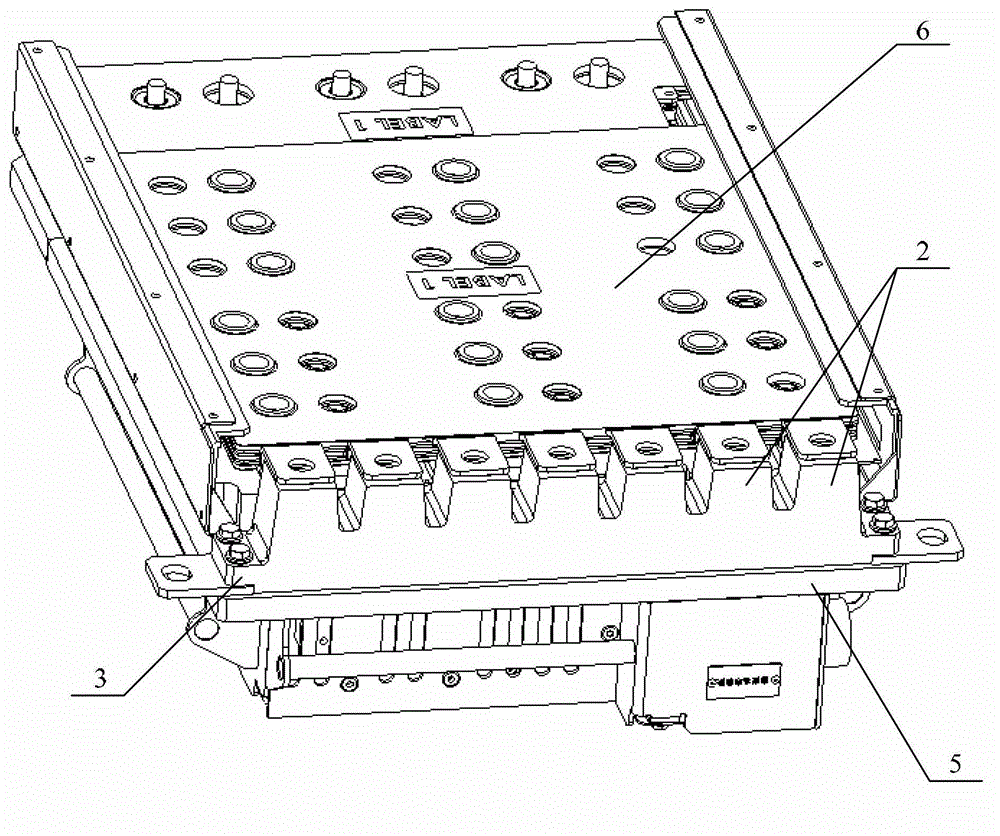

[0019] refer to figure 1 with 2 , figure 1 The first schematic diagram of the composite busbar insulation support device provided by the embodiment of the present invention; figure 2 It is the second schematic diagram of the composite busbar insulation support device provided by the embodiment of the present invention.

[0020] Such as figure 1 with 2 As shown, the composite busbar insulation support device provided in this embodiment includes a strip-shaped insulation support body 1, and a plurality of bosses 2 are arranged at intervals on the upper surface of the insulation support body 1, and the bosses 2 have nut installation counterbores 21 and bolt blind holes 22, the two ends of the insulating support body 1 have mounting ears 3, and the mounting ears 3 are provided with mounting holes 31 for mounting with the IGBT power module.

[0021] The material of the insulating support body 1 and the boss 2 can be sheet molding compound (SMC for short), and the insulating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com