Built-in type switch cabinet

A switchgear and center-mounted technology, which is applied in the direction of switchgear components, horizontally isolated switchgear, busbar/line layout, etc., can solve the problem of inability to truly judge whether the fracture is disconnected, potential safety hazards, invisible to users, etc. Problems, to achieve the effect of helping the heat dissipation of the contacts, solving the temperature rise of the contacts, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

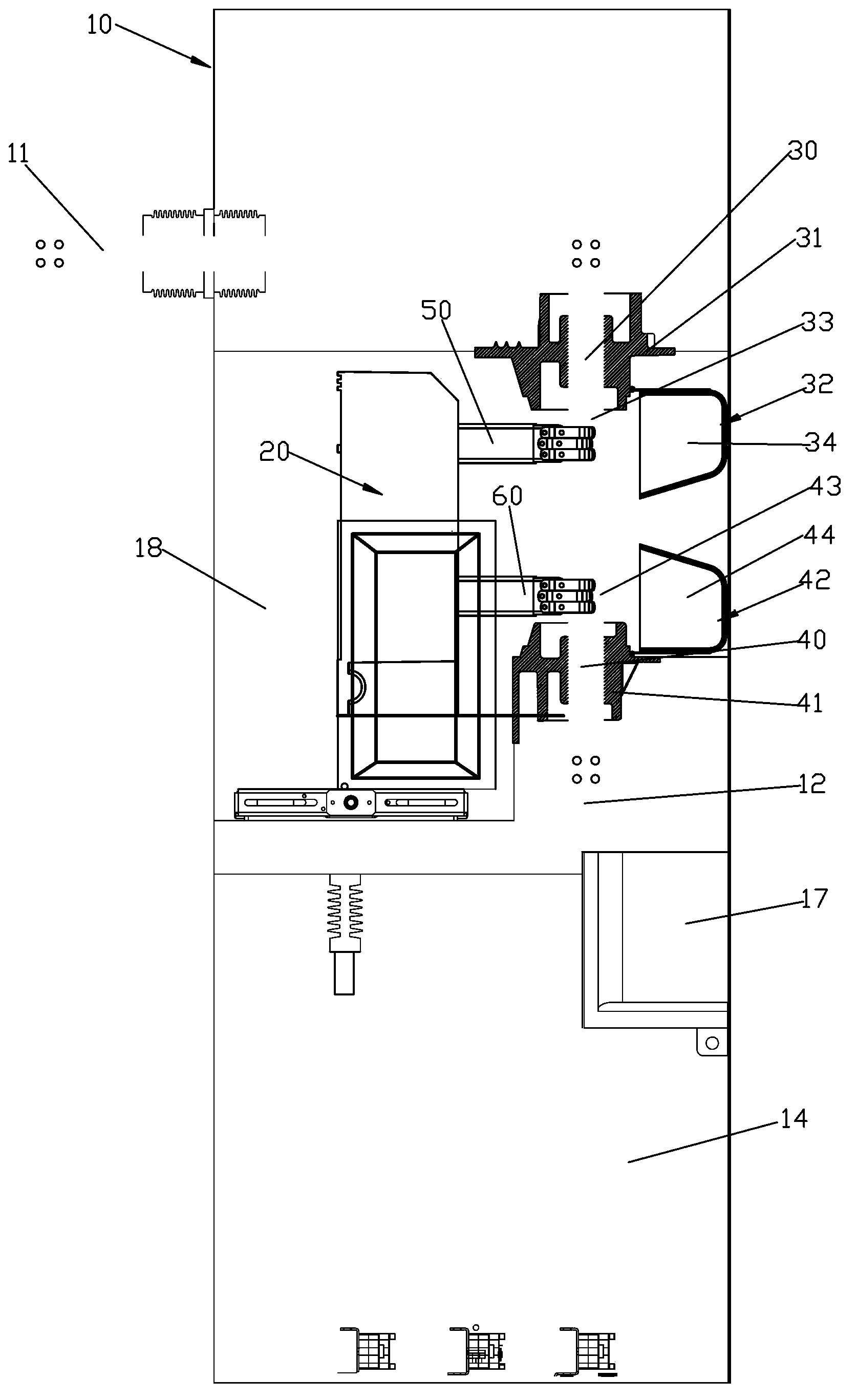

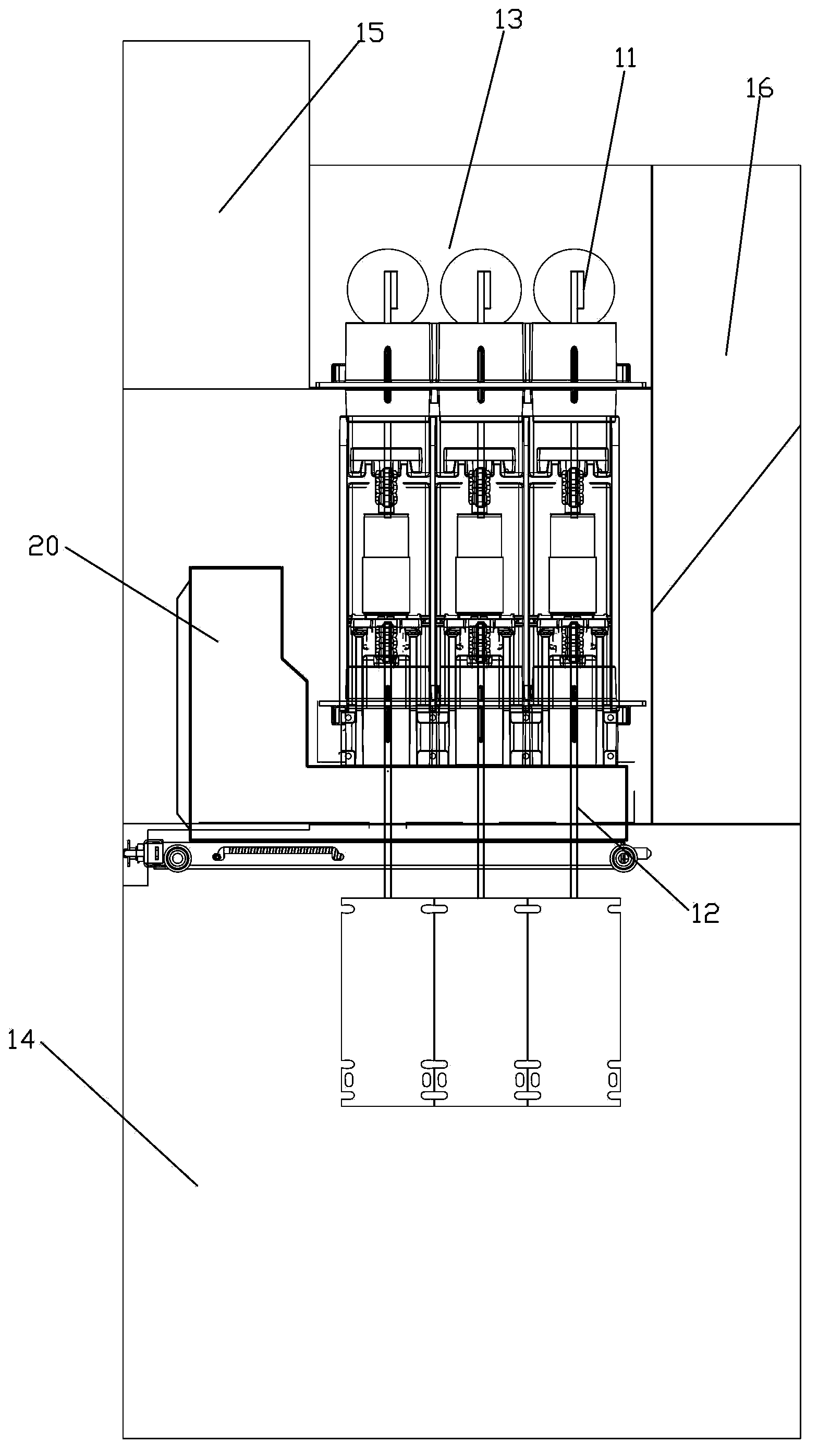

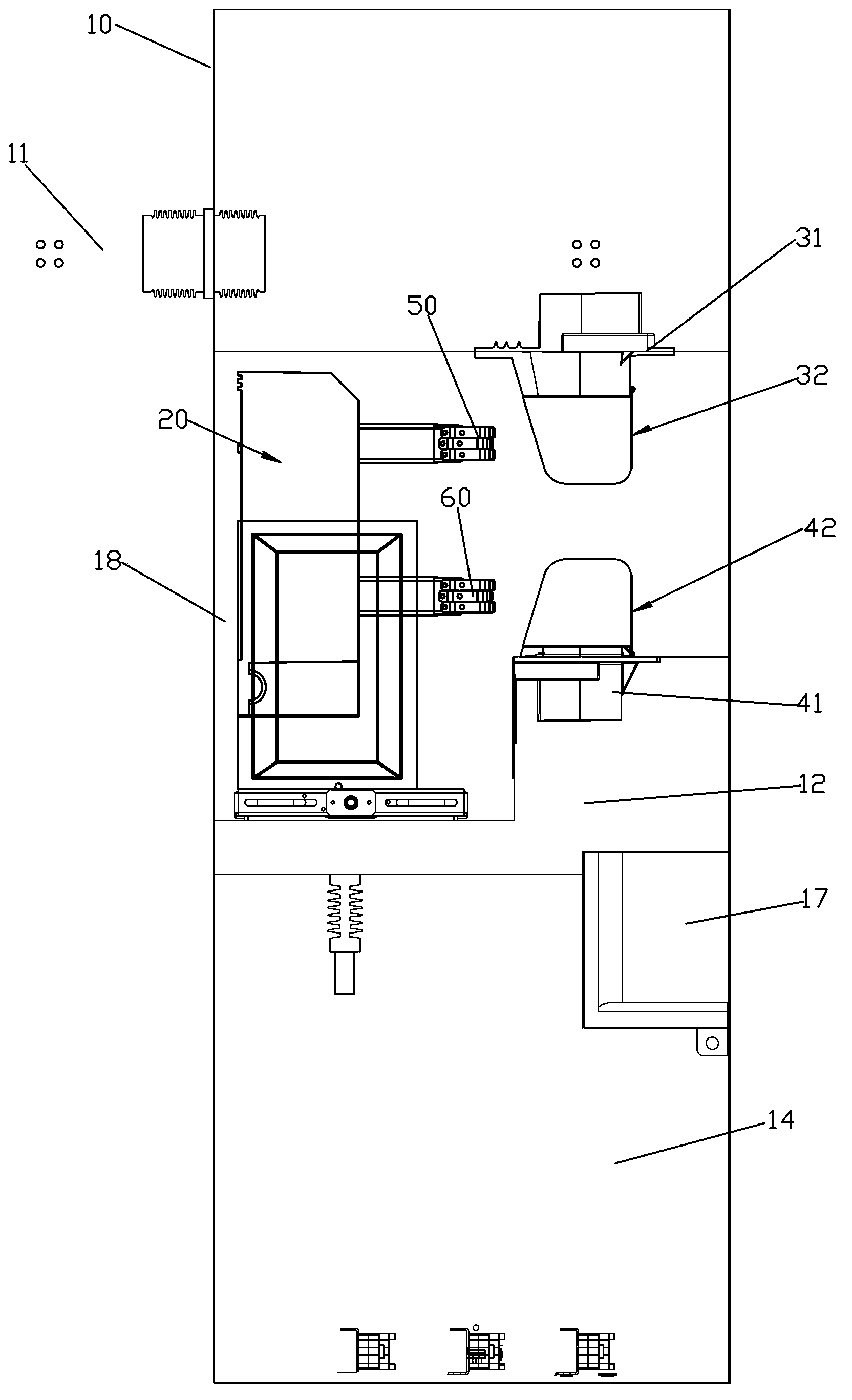

[0030] Please check Figure 1 to Figure 5 , middle-mounted switchgear, such as 12KV-40.5KV medium-voltage switchgear, including a cabinet 10 and a circuit breaker 20, the cabinet 10 has a front cabinet, the cabinet 10 is provided with a main busbar 11, a branch busbar 12, Bus room 13, cable room 14, low voltage room 15, circuit breaker room 18, arcing channel 16, CT17. In this embodiment, the cabinet body 10 is provided with left and right guide rails. The front cabinet board is provided with an opening and a cabinet door connecting the opening, the cabinet door is opened, and the circuit breaker is pushed back into the cabinet from the cabinet front of the front cabinet board.

[0031] The cabinet body 10 is provided with three-phase static contact units, and the three-phase static contact units are arranged in front and back. Each phase static contact unit includes an upper static contact 30 and a lower static contact 40 , the upper static contact 30 is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com