Display panel, preparation method thereof and display device

A display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the display panel picture quality, poor display panel picture quality, small display picture, etc., so as to improve the display picture quality and reduce fine bright spots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

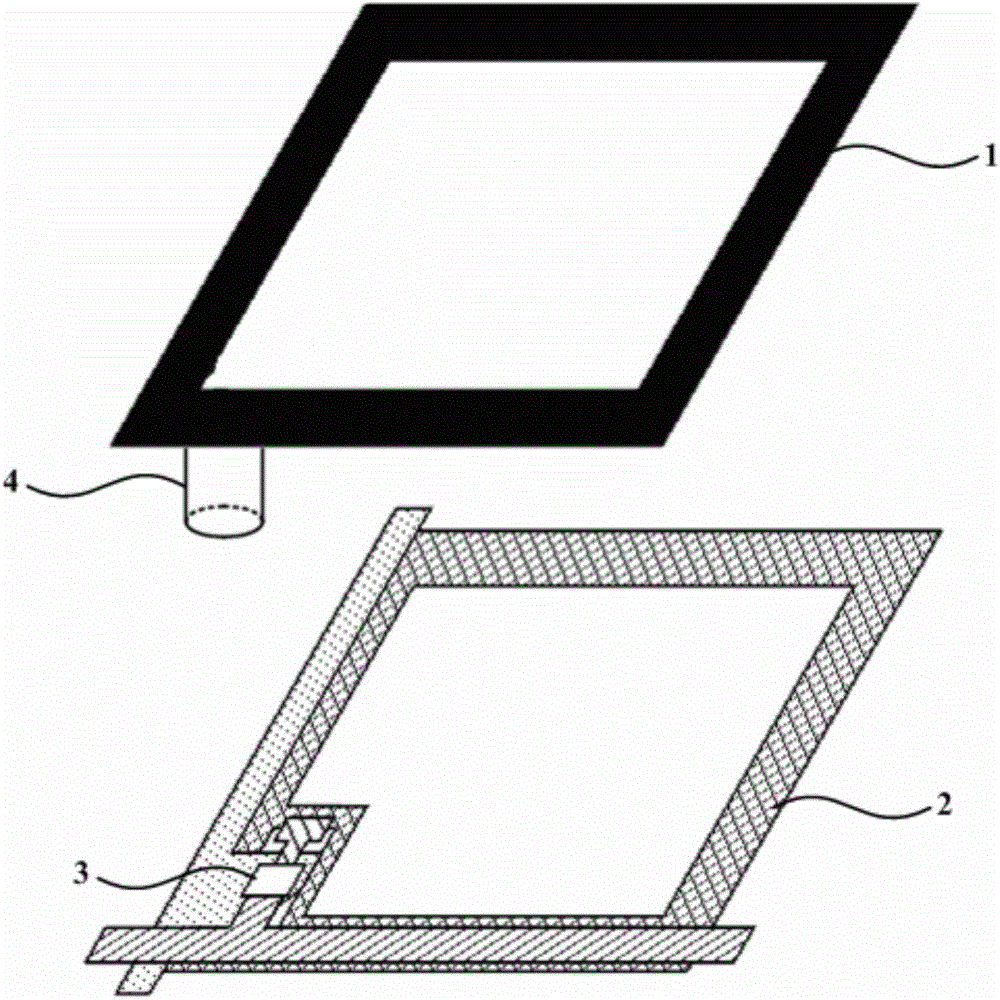

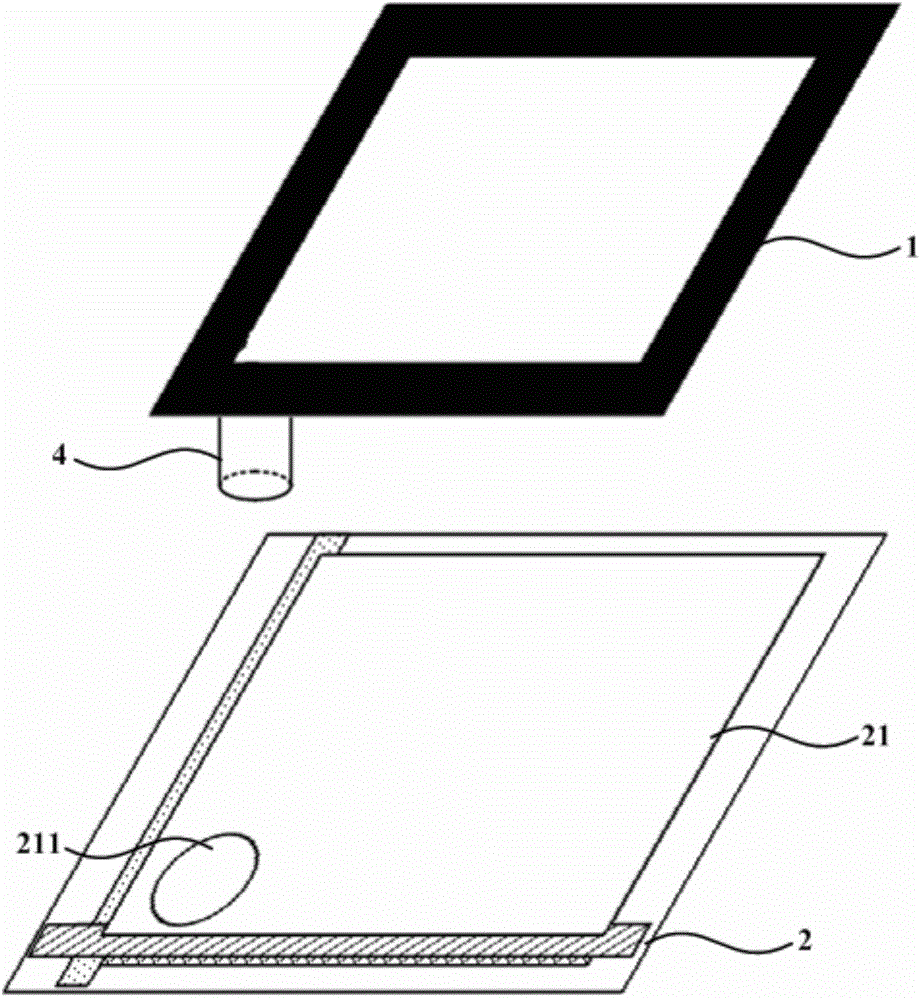

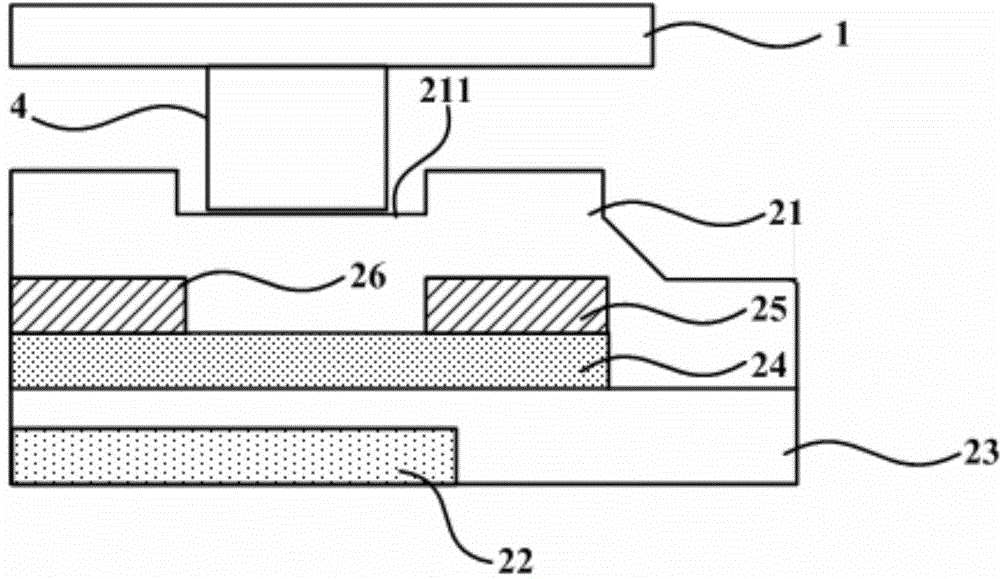

[0053] Embodiments of the present invention also provide a method for preparing a display panel, such as Figure 5 as shown, Figure 5 It is a schematic flow chart of a method for preparing a display panel according to an embodiment of the present invention, and the method includes:

[0054] Step 101, forming at least one spacer on the first substrate;

[0055] Step 102, forming an alignment layer on the second substrate, the alignment layer having a depression corresponding to each of the spacers;

[0056] Step 103 , boxing the first substrate provided with at least one spacer and the second substrate, each of the spacers abutting against the corresponding concave portion.

[0057] Preferably, the formation of the alignment layer on the second substrate further includes:

[0058] An adhesive layer is formed within each of the recessed portions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com