A cylindrical lens type naked eye 3D module

A naked eye, 3D technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as poor display effect and unstable structure, and achieve the effect of improving 3D display effect, improving assembly alignment accuracy, and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific implementation examples in conjunction with the accompanying drawings.

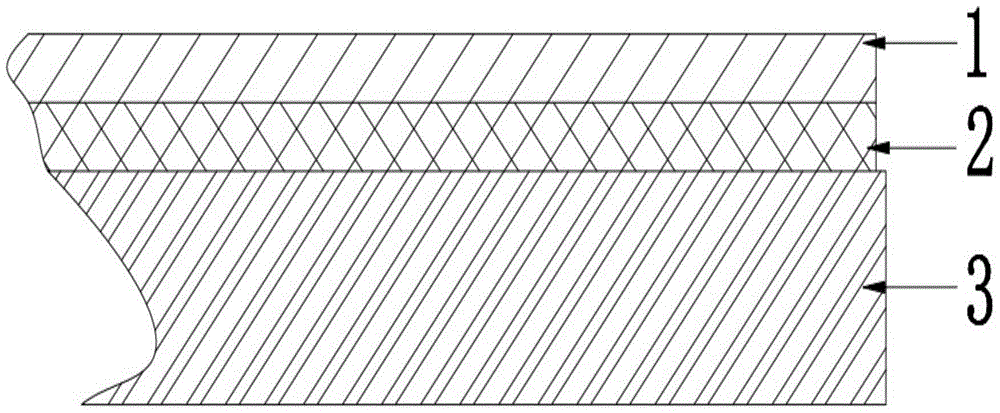

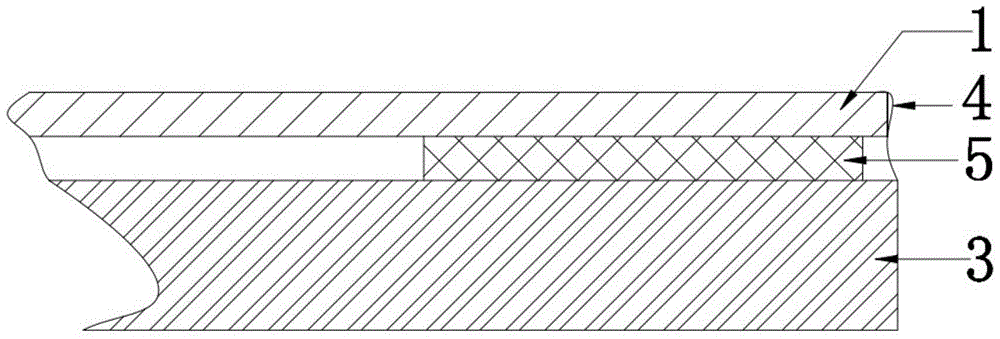

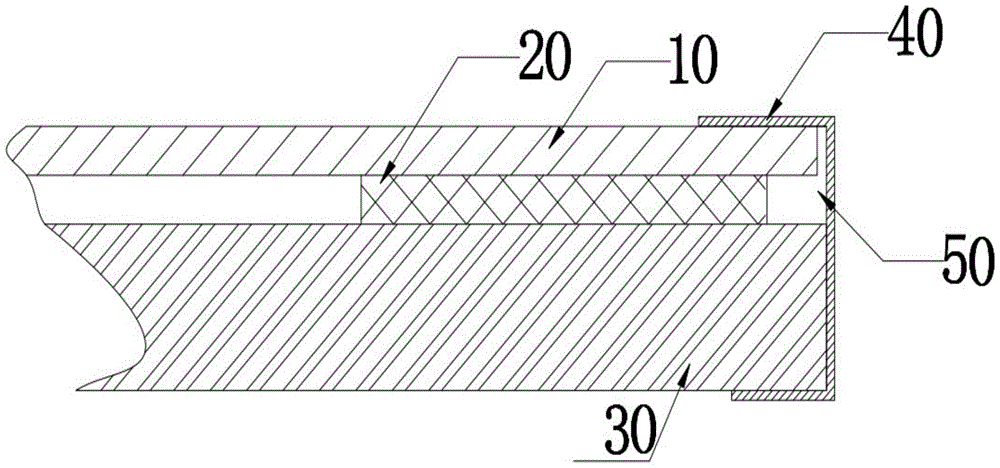

[0021] See image 3 The embodiment of the present invention provides a lenticular type naked eye 3D module, which includes a grating glass 10, a mat 20, and a liquid crystal screen 30 sequentially arranged from top to bottom. The top and bottom surfaces of the mat are both provided with double Surface adhesive layer (not shown);

[0022] It also includes a concave sheet metal frame 40; the grooves of the concave sheet metal frame are used to limit and clamp the component composed of the grating glass, the cushion material, the double-sided adhesive layer and the liquid crystal screen; the concave sheet metal frame The size of the groove wall in the groove is matched with the thickness of the component composed of the grating glass, cushion material, double-sided adhesive layer and liquid crystal screen;

[0023] A filling la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com