Detecting device for wax content in synthetic gas

A detection device and synthetic gas technology, applied in the direction of weighing by removing certain components, can solve the problem of inability to detect the wax content of synthetic gas, so as to avoid excessive wax content, solve the problem of wax clogging equipment, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

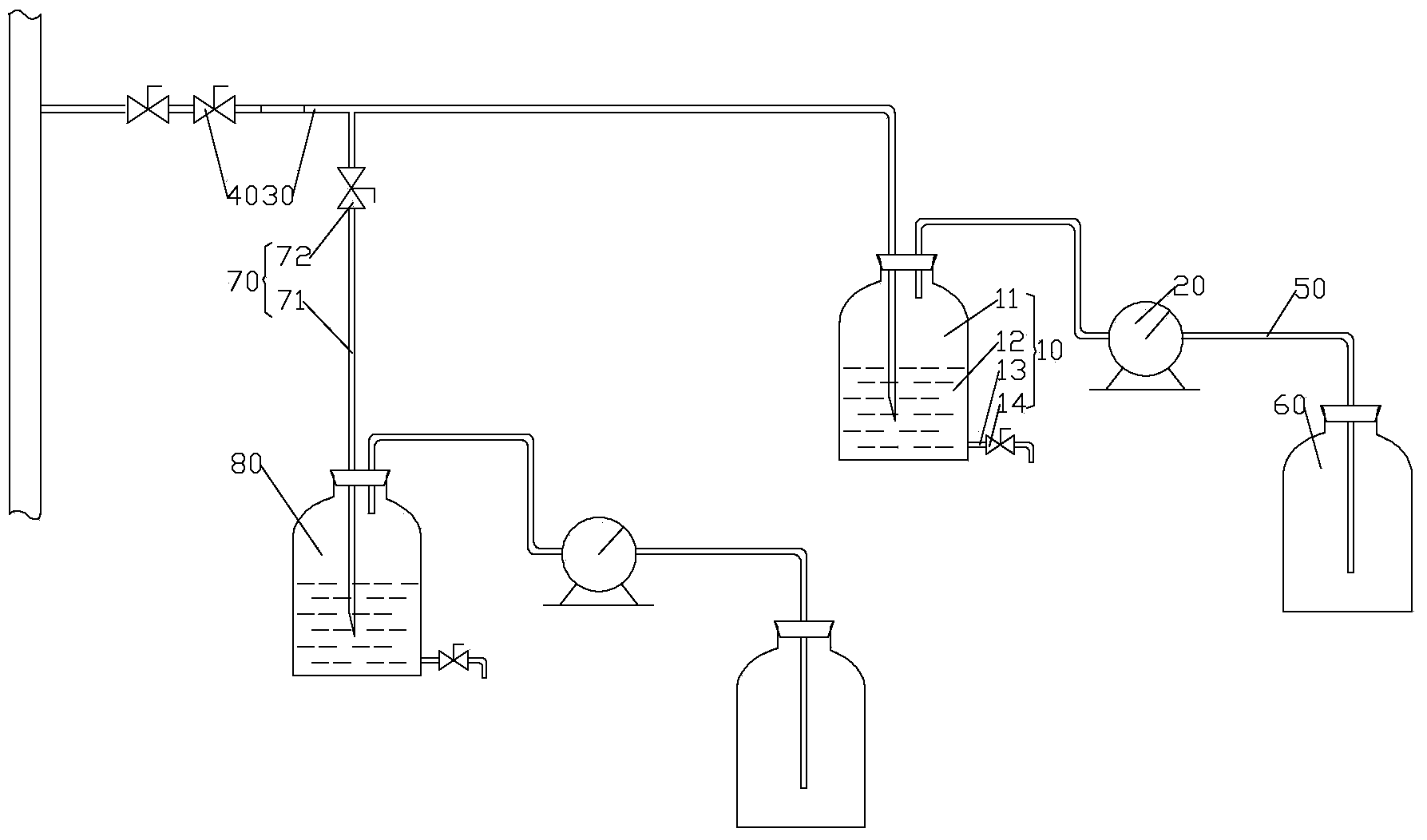

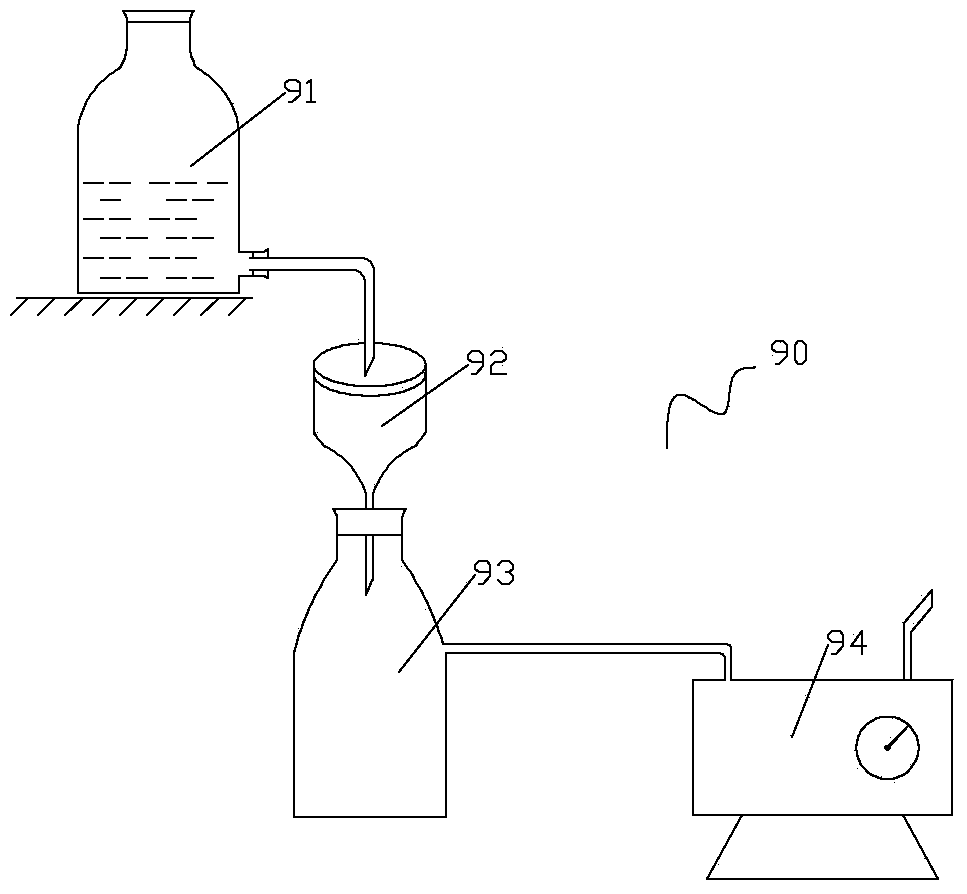

[0025] The invention provides a detection device for wax content in synthesis gas. Such as figure 1 and figure 2 As shown, the detection device includes a first cooling part 10, a flow detection element 20 and a weighing part, and the synthesis gas is passed into the first cooling part 10 to cool and separate wax and gas; the flow detection element 20 is arranged on the first cooling part 10 The outlet port of the first cooling unit 10 is used to detect the volume of gas discharged from the first cooling unit 10; the weighing unit weighs the initial mass and cooling mass of the first cooling unit 10. When using the detection device in the present invention, the wax and gas are separated in the first cooling unit 10, and the wax condenses into a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com