Non-destructive welded joints of inner-coated steel pipes in long-distance pipelines

A technology of welded joints and pipeline bands, which is applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, passing components, etc., which can solve the problems of eddy currents, affecting the diameter of pipelines, and the quality of rust removal is difficult to reach the factory operation level and other problems, to achieve the effect of high operability and increase process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

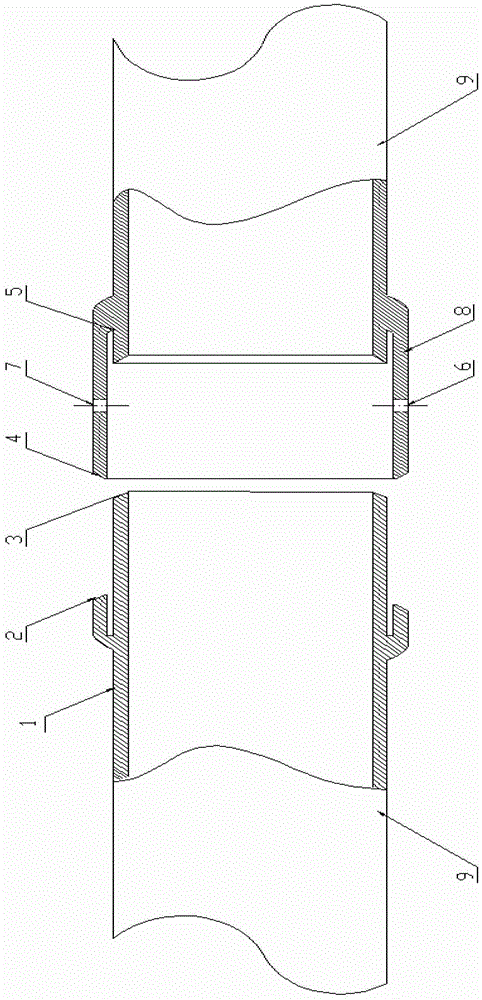

[0019] Such as figure 1 , is a structural schematic diagram of the present invention, which is a non-destructive welded joint of a long-distance pipeline with an inner coating steel pipe, including a flared welded joint 8 and a shrinked welded joint 1 that are inserted and welded to each other, and both welded joints have a certain thickness. The end wall, as shown in the figure, the width of the shaded part is the thickness of the end wall, the inside of the flared welded joint and the top of the end wall of the necked welded joint have an insertion groove for insertion fit, and the necked welded joint The lead-in groove 3 and the lead-in groove 5 of the flared welded joint are sized to match each other; the top of the end wall of the flared welded joint and the outer wall of the shrinked welded joint have mutually matched welded grooves, wherein the welded groove of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com