Guide rod and guide device

A guide rod and guide head technology, applied in the field of guide rods, can solve the problems of poor guidance accuracy, damage to copper tubes and fins, and inability to guide copper tubes, so as to prevent damage and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to solve the problems of poor guiding accuracy and imprecise pipe threading process, a guide rod and a guiding device are proposed to improve the accuracy of guiding and the precision of pipe threading process.

[0030] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

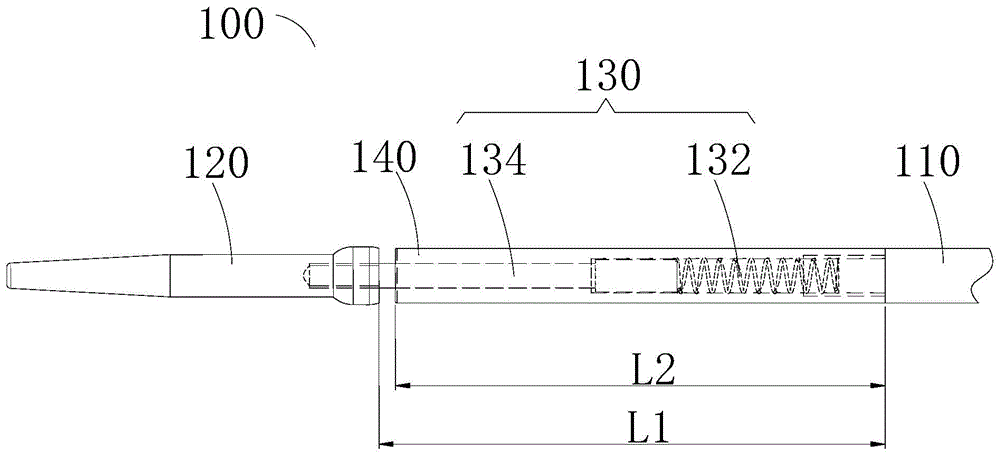

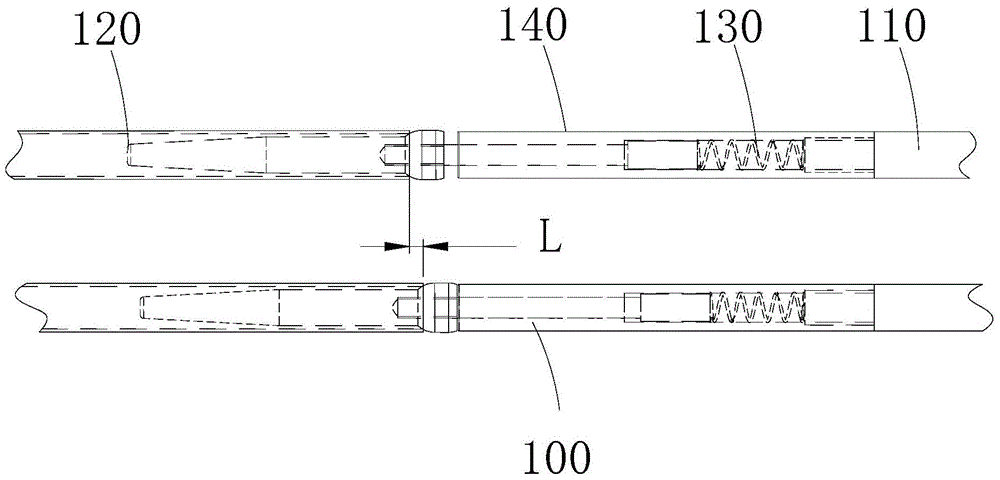

[0031] see figure 1 As shown, it is a schematic front view of the guide rod of the present invention. The guide rod 100 of the present invention includes a body 110 , a guide head 120 and an elastic connection assembly 130 . Both the body 110 and the guide head 120 are rod-shaped, and can be conveniently penetrated into the copper pipe to guide its axial position during use.

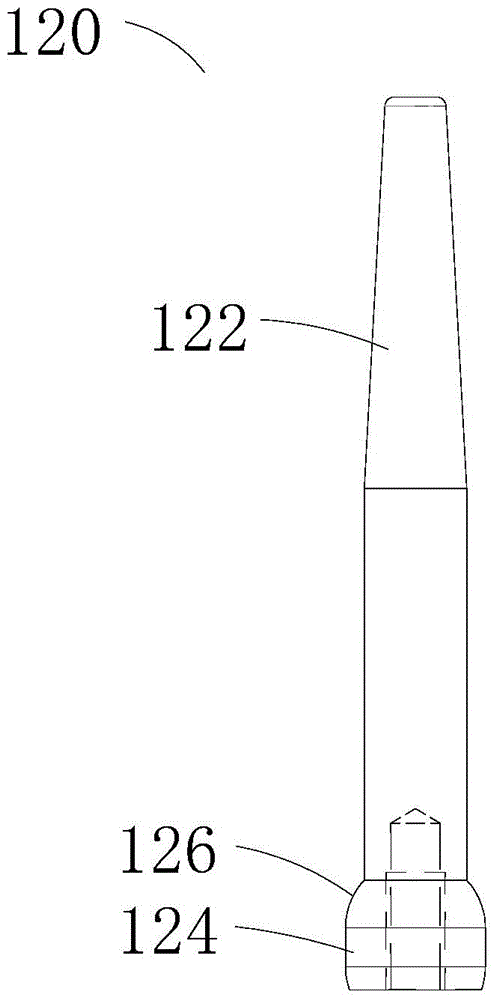

[0032] see figure 2 As shown, it is a schematic front view of the guide head of the guide rod of the present invention, the guide head 120 includes a larger end 124 and a smaller end 122, and the guide hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com