A kind of self-cleaning aramid fiber membrane and its preparation method and application in gas separation

A self-cleaning and aramid fiber technology, applied in the field of self-cleaning aramid fiber film and its preparation, can solve the problems of low reaction efficiency and poor durability, and achieve high temperature resistance, excellent performance and excellent self-cleaning function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

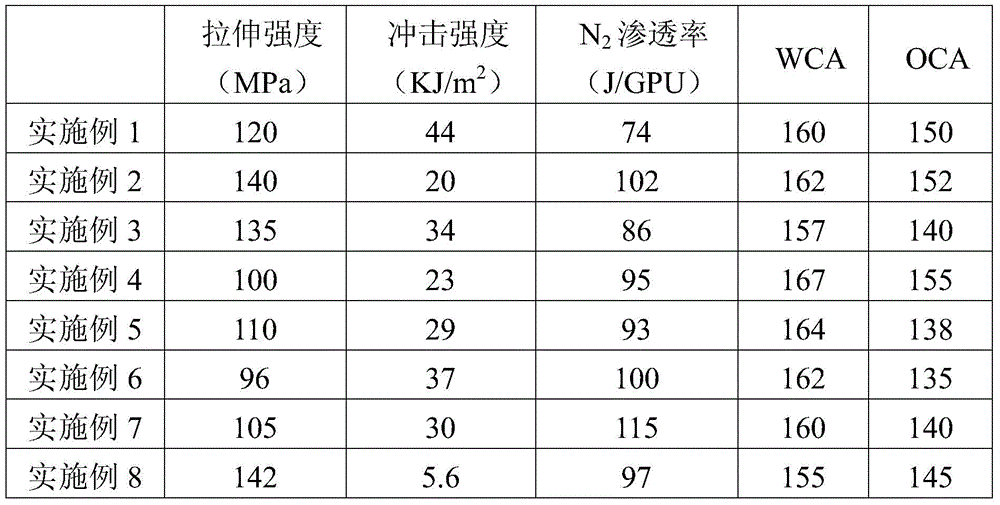

Examples

Embodiment 1

[0040] Example 1: Preparation of a self-cleaning aramid membrane

[0041] (1) Add KOH to dimethyl sulfoxide (DMSO), stir until KOH is completely dissolved, then add aramid II, stir at room temperature to form a solution with a mass fraction of 4%, and the amount of KOH is N equivalent in aramid II 1 times. Then add PEG-1000 with 10% aramid mass to the above solution, stir evenly to form a casting solution, and then vacuum degas the casting solution for use. Then spread the casting solution on a smooth glass plate, and use a scraper to scrape out a 300-400um film. The scraped film was evaporated at 20°C for 10 seconds, and then immersed in water to gel until the film was detached from the glass plate to obtain a gel film. The gel film was soaked in water for 4 days to completely remove the porogen and solvent. Finally, it is treated at 120° C. until the film is completely dry to obtain an aramid fiber film.

[0042] (2) Put the aramid membrane prepared in (1) into the fluori...

Embodiment 2

[0046] Example 2: Preparation of a self-cleaning aramid membrane

[0047] (1) Add potassium tert-butoxide to N,N-dimethylformamide, stir until potassium tert-butoxide is completely dissolved, then add aramid fiber II, stir at room temperature to form a solution with a mass fraction of 5%, tert-butyl The dosage of potassium alkoxide is 0.8 times of N equivalent in aramid fiber II. Then add PVP-25 with 20% aramid mass to the above solution, stir evenly to form a casting solution, and then vacuum degas the casting solution for use. Then spread the casting solution on a smooth glass plate, and use a scraper to scrape out a 300-400um film. The scraped film was evaporated at 30° C. for 30 seconds, and then immersed in water to gel to obtain a gel film. The gel film was soaked in water for 7 days to completely remove the pore-forming agent and solvent. Finally, it is treated at 150° C. until the film is completely dry to obtain an aramid fiber film.

[0048] (2) Put the aramid fil...

Embodiment 3

[0049] Example 3: Preparation of a self-cleaning aramid membrane

[0050] (1) Add NaH to N-methylpyrrolidone, stir until NaH is completely dissolved, then add aramid fiber III, stir at room temperature to form a solution with a mass fraction of 8%, and the amount of NaH is 1.5 times the N equivalent in aramid fiber III . Then add PEG-600 with 30% aramid weight to the above solution, stir evenly to form a casting solution, and then vacuum degas the casting solution for use. Then spread the casting solution on a smooth glass plate, and use a scraper to scrape out a 300-400um film. The scraped film evaporated the solvent at 25°C for 20 seconds, and then sank into water to gel to obtain a gel film. The gel film was soaked in water for 7 days to completely remove the pore-forming agent and solvent. Finally, it is treated at 80° C. until the film is completely dry to obtain an aramid fiber film.

[0051] (2) Put the aramid membrane prepared in (1) into the fluorine-containing epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com