pinch fitting

A technology of clamping pipe and joint seat, applied in the field of pipe joints, to achieve the effect of uniform clamping force, convenient assembly and disassembly, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

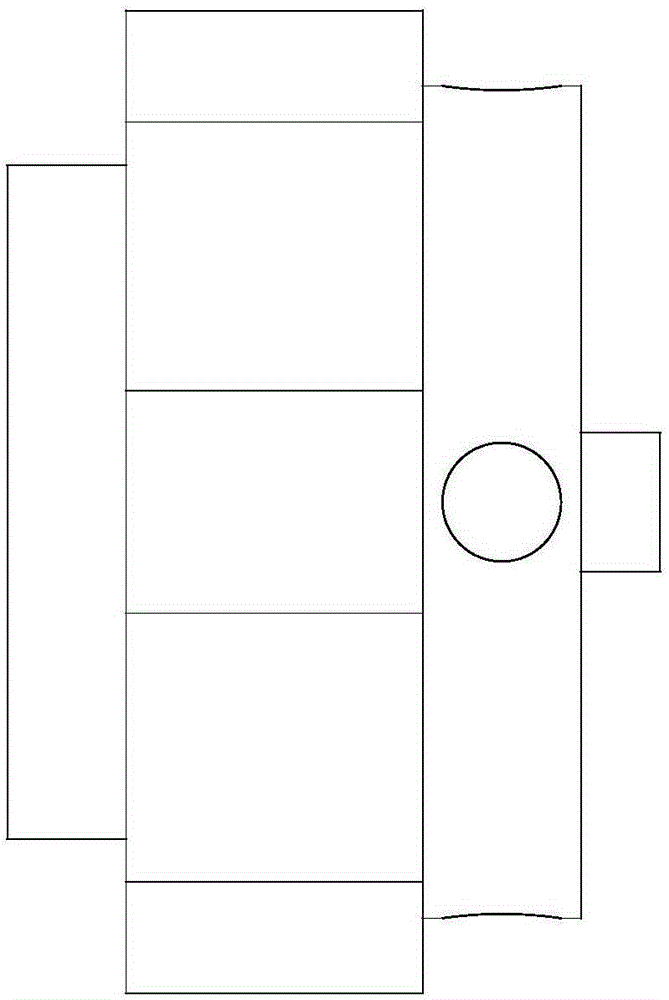

[0029] Such as Figure 1-9 As shown, the pinch joint of this embodiment includes a joint seat 3, a taper sleeve 2 and a clamping head 1, wherein: one end of the joint seat 3 has a socket 31 for inserting into the connected hose, and the joint seat 3 The center of the center has flow holes 32 connecting the two ends of the joint seat 3, and the side of the joint seat 3 has external threads; the two ends of the taper sleeve 2 are oppositely provided with two sets of contraction grooves 21, and the two sets of contraction slots 21 are arranged alternately along the circumference of the taper sleeve 2, Thereby, the deformation of the taper sleeve 2 is flexible, and the inner surface of the taper sleeve 2 has two sets of raised clamping blocks 22. The same group of clamping blocks 22 is located at the same height and is evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com