Direct-current bus voltage ripple compensation method

A DC bus voltage and ripple compensation technology, which can be applied to DC circuits to reduce harmonics/ripples, etc., can solve the problems of increased material cost and assembly cost, large capacitor volume, high cost, etc., and achieves material cost and performance. The effect of reducing consumption, prolonging life and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

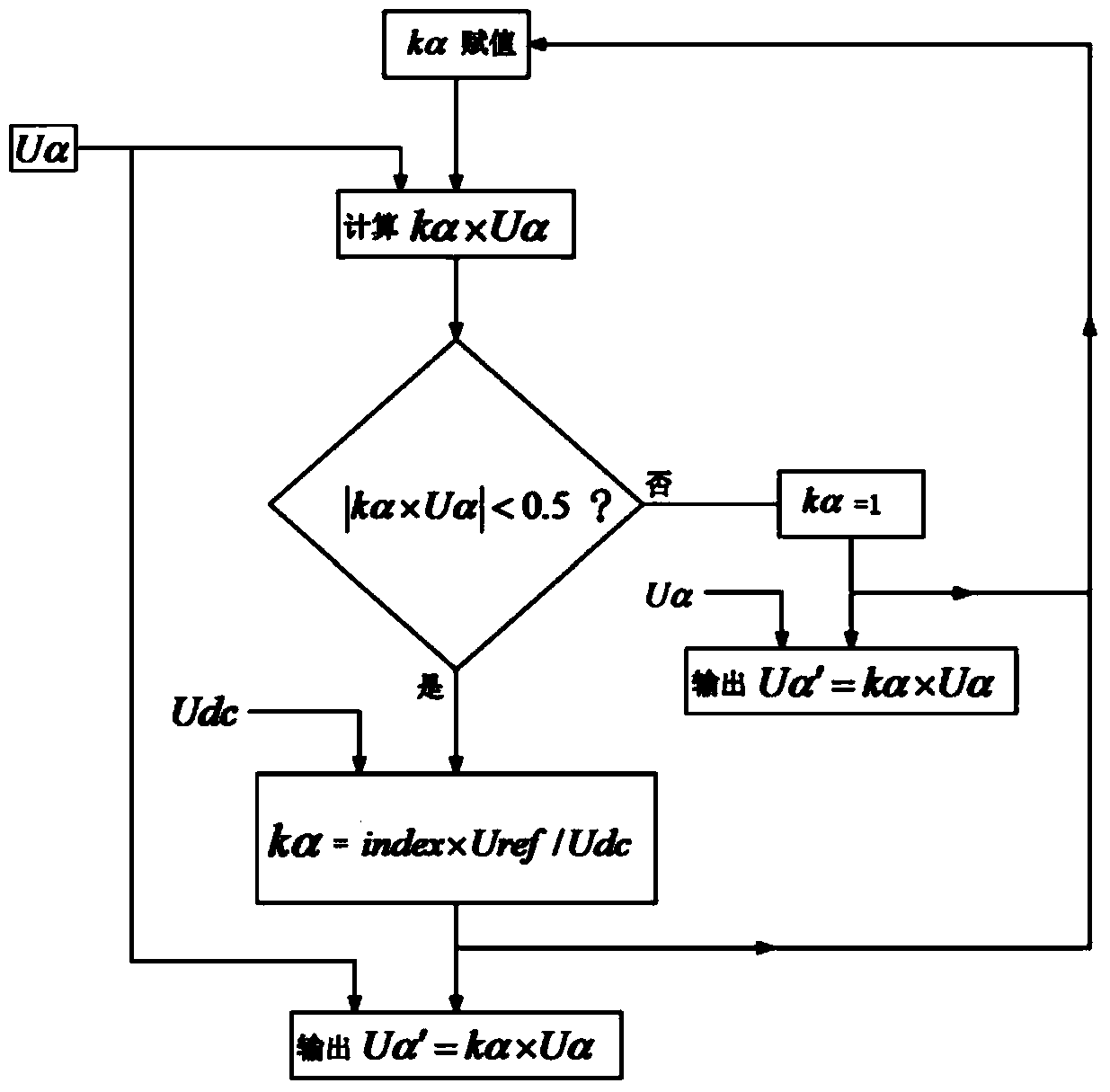

[0021] This DC bus voltage ripple compensation method adopts figure 2 The software control logic shown: Compensate and calculate the α-axis voltage component Uα and β-axis voltage component Uβ respectively output by inverse PARK transformation to obtain the corresponding α-axis compensated voltage component Uα′ and β-axis voltage component Uβ′, Then input the voltage component Uα' after α-axis compensation and Uβ' after compensation on the β-axis to the SVPWM circuit;

[0022] The voltage component Uα' after α-axis compensation and the voltage component Uβ' after β-axis compensation are obtained by the following calculation method:

[0023] Uα'=kα×Uα

[0024] Uβ′=kβ×Uβ

[0025] And kα, kβ are determined by the following formula:

[0026] kα = index ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com