Remote fault diagnosis system and method for concrete batching plants

A fault diagnosis system and fault diagnosis technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of inability to troubleshoot, inconvenient transportation, and time-consuming problems, achieve obvious social and economic benefits, and solve the problems of long maintenance cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

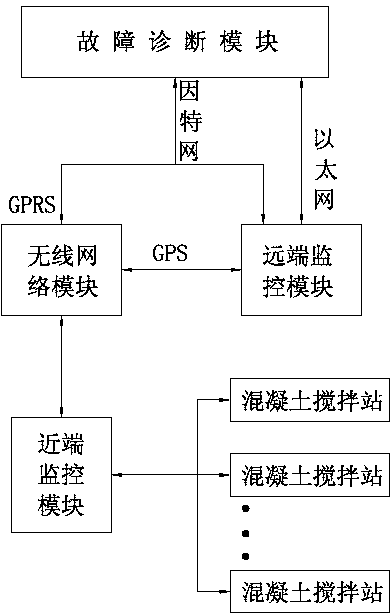

[0025] Such as figure 1 The shown remote fault diagnosis system for a concrete mixing plant includes at least one concrete mixing plant, a near-end monitoring module, a wireless network module, a remote monitoring module, and a fault diagnosis module.

[0026] The near-end monitoring module includes at least one computer, which can monitor the production process parameters, production data, actuators and sensors of the concrete mixing plant in real time, and save the data in the local hard disk.

[0027] Described wireless network module comprises GPRS wireless transceiver module and GPS wireless transceiver module, and described GPRS wireless transceiver module can upload the data of near-end monitoring system to fault diagnosis module by GPRS network and Internet; Described GPS wireless transceiver module can stir The geographical location information of the station is sent to the remote monitoring module; the remote monitoring module and the fault diagnosis module are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com