Optical fiber probe with polarization maintaining property and preparation method thereof

An optical fiber probe and polarization-maintaining fiber technology, applied in the field of weak optical signal detection, can solve the problems of weakening signal light intensity, reducing signal-to-noise ratio, reducing spatial resolution, etc. good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the optical fiber probe with polarization-maintaining properties is as follows:

[0037] (1) Select an elliptical core polarization-maintaining fiber, cut it to a length of 12 cm, remove the resin coating, and obtain a bare fiber. The bare fiber is cleaned with alcohol and deionized water in turn.

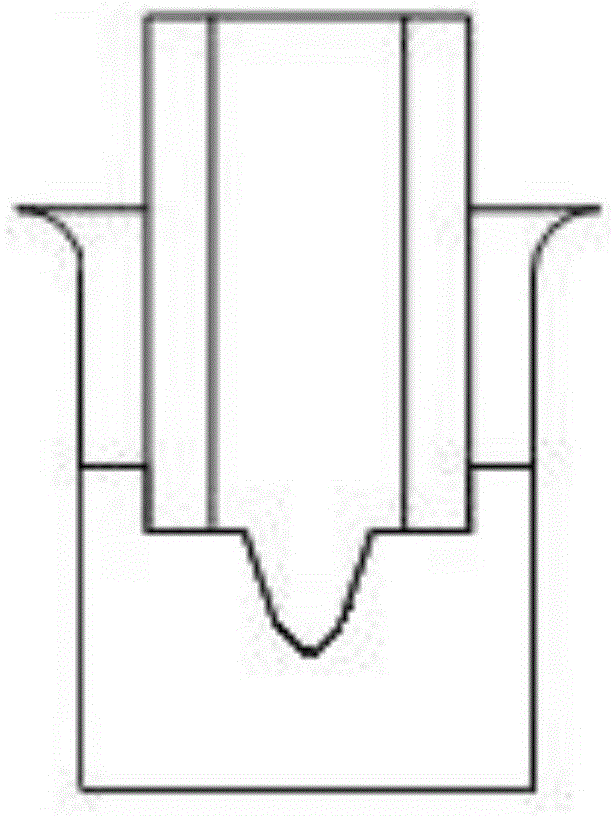

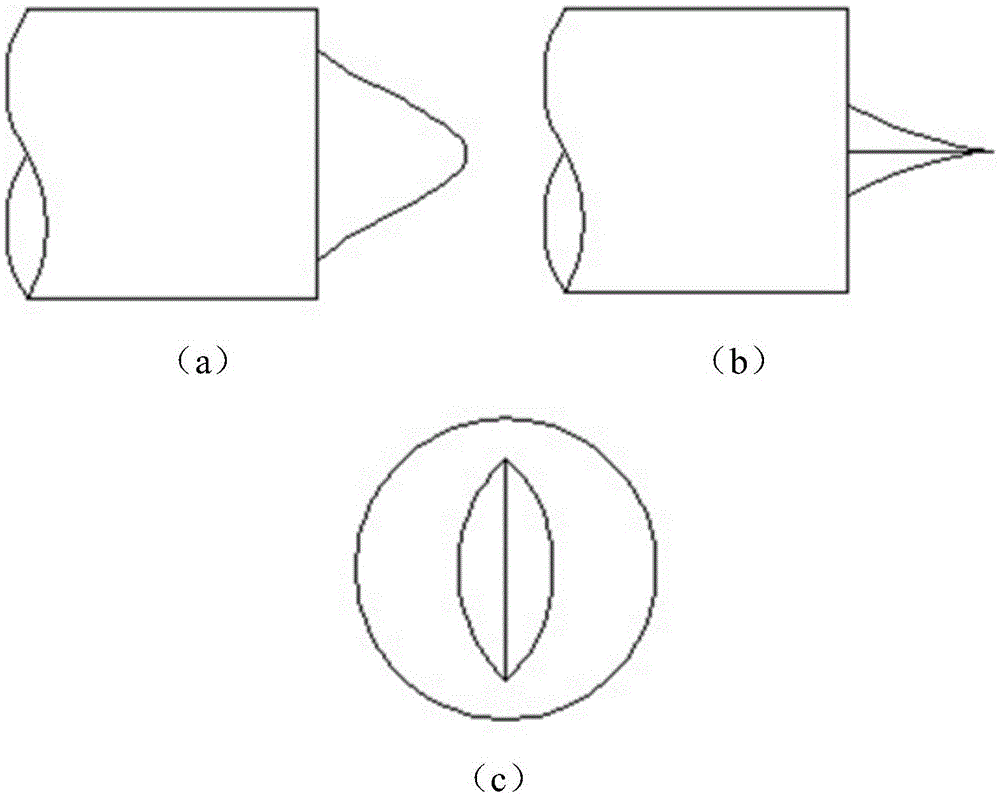

[0038] (2) Mix HF solution with a mass fraction of 40%, deionized water and a NH4F solution with a mass fraction of 40% in a volume ratio of 3:5:40 to obtain an etching solution, and cover the surface of the etching solution with a layer of glycerin As the protective liquid, the thickness of the protective liquid was 2 mm. like figure 1 As shown, a part of the bare fiber was inserted vertically into the etching solution, so that the lower end of the fiber was exposed to the etching solution, and after etching for 10 hours, the needle tip was formed. The needle tip is duckbill-like, the lower end surface of the needle tip is oval, the two curved su...

Embodiment 2

[0044] The preparation method of the optical fiber probe with polarization-maintaining properties is as follows:

[0045] (1) Select an elliptical core polarization-maintaining fiber, cut it to a length of 10 cm, remove the resin coating, and obtain a bare fiber. Clean the bare fiber with alcohol and deionized water in turn.

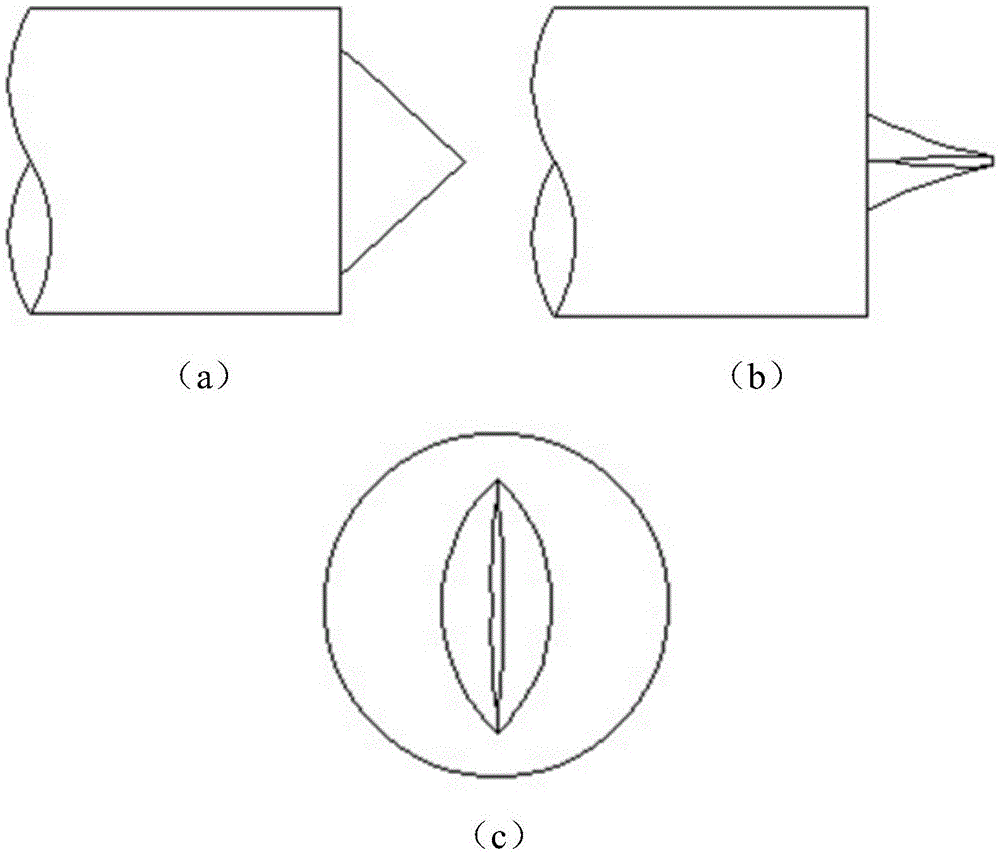

[0046] (2) Mix HF solution with a mass fraction of 40%, deionized water and a NH4F solution with a mass fraction of 40% in a volume ratio of 3:5:40 to obtain an etching solution, and cover the surface of the etching solution with a layer of glycerin As the protective liquid, the thickness of the protective liquid was 2 mm. The bare fiber part was inserted vertically into the etching solution, so that the lower end of the fiber was exposed to the etching solution, and after etching for 10 hours, the needle tip was formed. The needle tip is duckbill-like, the lower end surface of the needle tip is oval, the two curved surfaces forming the duckbill structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com