A self-priming Venturi scrubber performance test system

An experimental system, Venturi technology, is applied in the field of self-priming Venturi scrubber performance experiment system, which can solve the problems that threaten the human living environment and cannot test the reliability of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

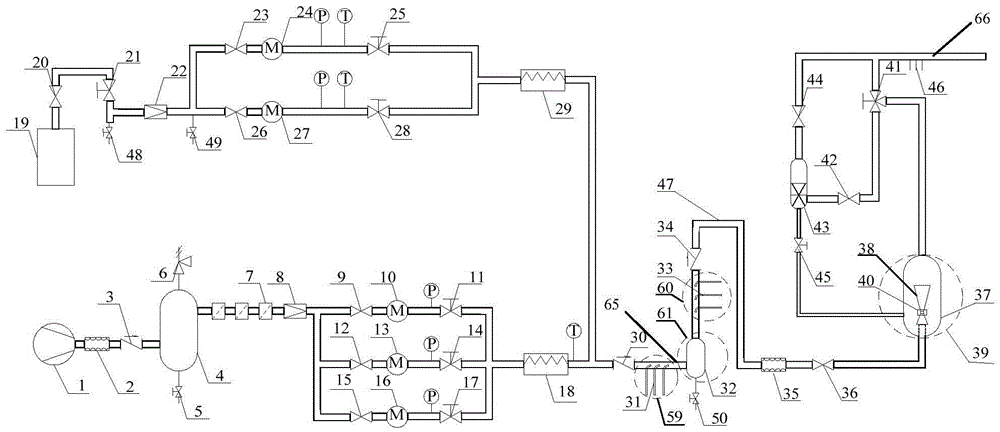

[0028] Such as figure 1 As shown, the experimental system consists of a self-priming Venturi water washer, an air supply circuit, a steam supply circuit, a gas mixing distribution circuit, an inlet sampling section, a self-priming Venturi water washer injection characteristic measurement circuit, an outlet sampling section and corresponding The data acquisition system consists of the outlet of the air supply circuit and the outlet of the steam supply circuit converging and then connected to the inlet of the gas mixing and distribution circuit, the outlet of the gas mixing and distribution circuit is connected to the inlet sampling section, and the outlet of the inlet sampling section is connected to the self-priming Venturi water scrubber , The self-priming Venturi water scrubber is externally connected to the injection characteristic measurement circuit.

[0029] Such as figure 1As shown, the air supply circuit is composed of an air compressor 1, an air storage tank 4, a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com