External pilot balance type kingston valve

A balanced, sea-opening valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of manual valve opening, easy cleaning, easy blocking of pilot holes, etc., and achieve the effect of long service life and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

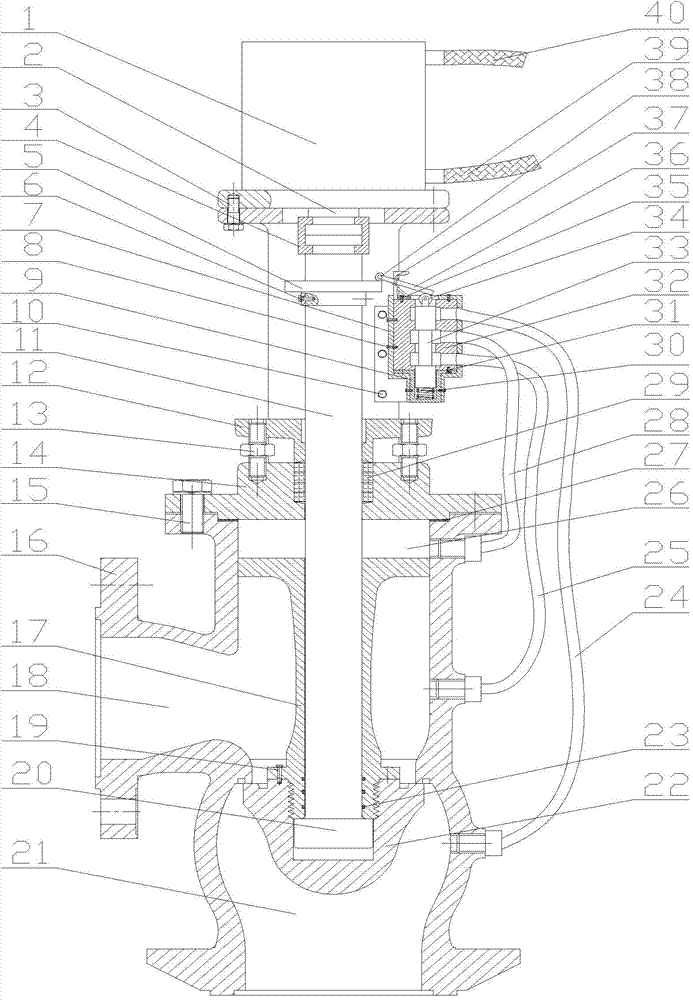

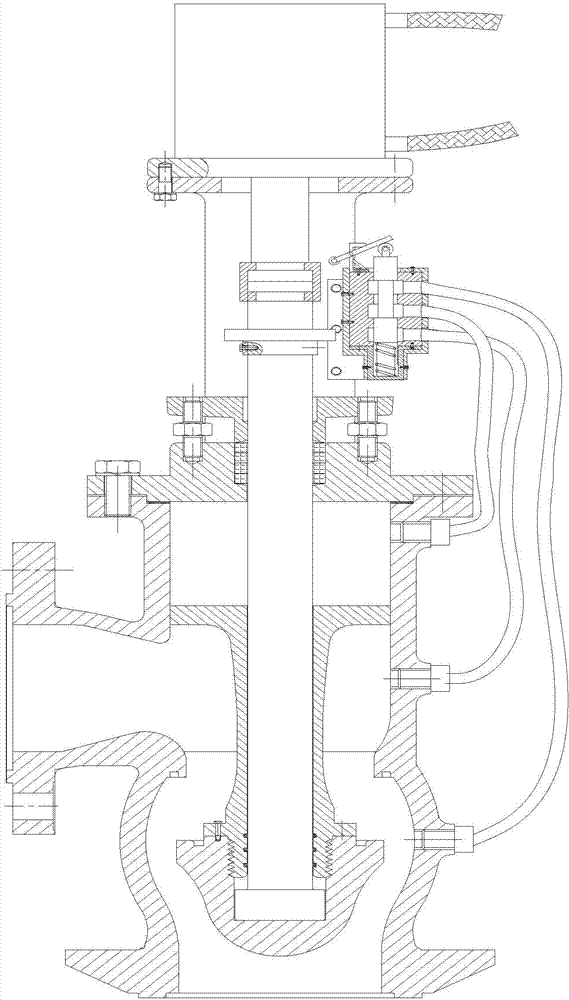

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~4 , the present invention mainly includes hydraulic cylinder parts 1-3, 39-40, valve stem parts 5-6, 11, 20, etc., packing parts 12-13, 29, valve cover parts 14-15, etc., valve body part 16, Piston part 17, valve head part 19-20, 22-23, pilot pipe control part 24-25, 27, 30-38, etc.

[0019] There are first-second hydraulic cylinder oil ports 39 and 40 on the upper and lower sides of the double-acting hydraulic cylinder 1, and the up-and-down movement of the piston rod 2 is driven by the different oil in and out sequences of the first-second hydraulic cylinder oil ports 39 and 40 , the piston rod 2 and the valve rod 11 are connected together through the adapter sleeve 4 . The double-acting hydraulic cylinder 1 is connected to the valve cover 14 through four first bolts 3 .

[0020] The reversing block 5 is fixed on the corresponding pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com