Ship gas/dual fuel engine LNG gasifying system based on exhaust energy recycling and control method thereof

A dual-fuel engine and energy recovery technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as limited installation space, increased heat transfer loss, and increased heat absorption, so as to improve the working environment and improve utilization The effect of high efficiency and heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in more detail below in conjunction with the accompanying drawings:

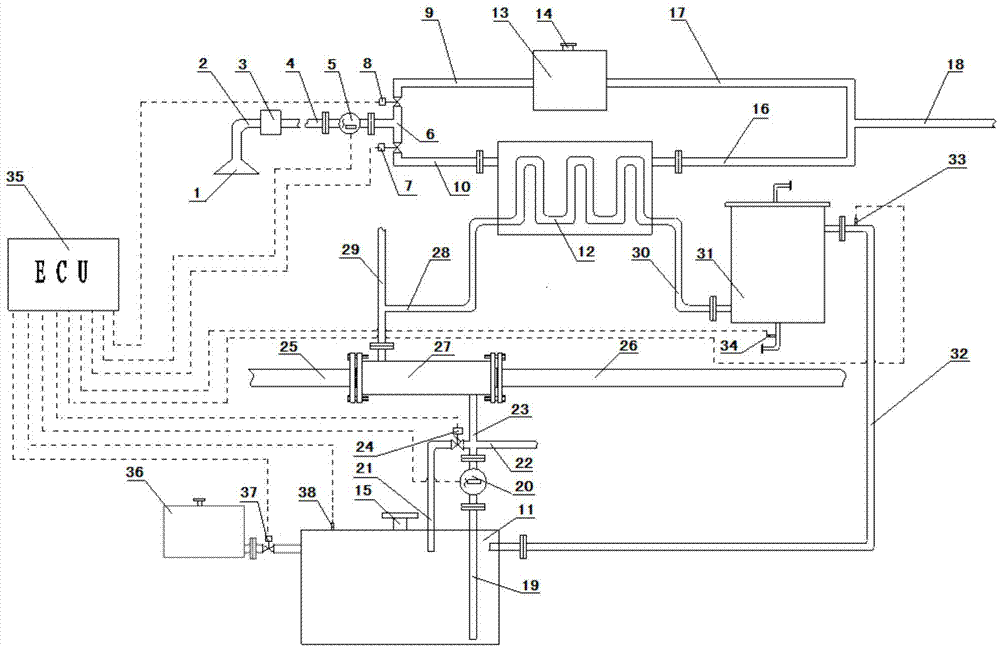

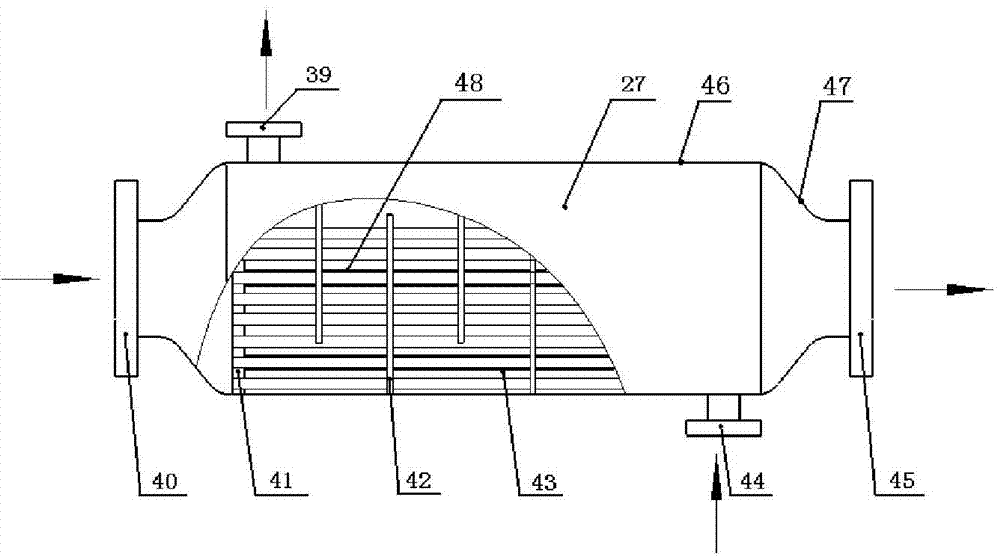

[0021] combine Figures 1 to 5 , LNG heating system for marine gas / dual fuel engine based on exhaust energy recovery, including: liquid collecting pan 1, liquid filter 3, adjustable flow pumps 5 and 20, remote control shut-off valves 24 and 37, heat exchange medium tank 11, Radiator 12, automatic replenishment tank 36, liquid level sensor 38, engine expansion tank 13, remote control butterfly valves 7 and 8, exhaust heat exchanger 27, LNG vaporizer 31, pipelines 2, 4, 6 and 9, etc. Lan and control system 35. The LNG system consists of two cycles: closed cycle and open cycle. The closed cycle is composed of heat exchange medium tank 11, adjustable flow pump 20, exhaust heat exchanger 27, LNG vaporizer 31, pipelines 19, 23, 28, 30, 32 and flanges. The adjustable flow pump 20 pumps the heat exchange medium through the pipeline 19 inserted into the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com