Large-deformation broken surrounding rock roadway management method

A technology for crushing surrounding rock and large deformation, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of restricting mine safety production and profitability, the deformation of surrounding rock cannot be effectively controlled, and the need for three or four supports, etc. problems, to achieve significant social benefits, convenient implementation, and increased anchorability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0026] The treatment method of the large-deformation broken surrounding rock roadway of the present invention, the steps are as follows:

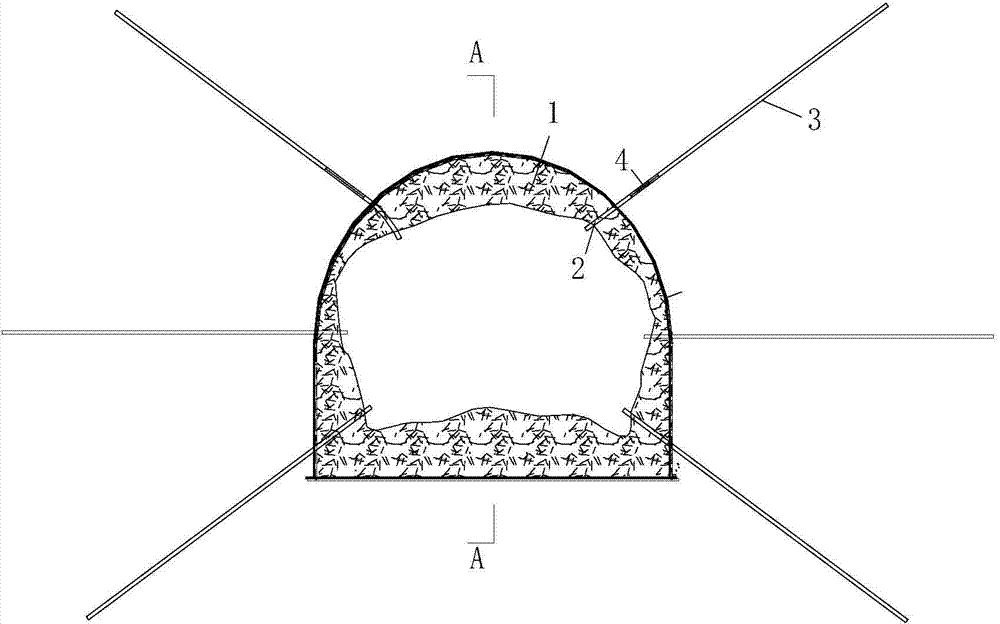

[0027] a, first construct deep grouting holes 3 at the top, side and bottom corners of the deformed roadway 1; Yes: the depth of the top hole is 20-40m, the depth of the side grouting hole is 5-20m, the depth of the bottom hole is 5-15m,

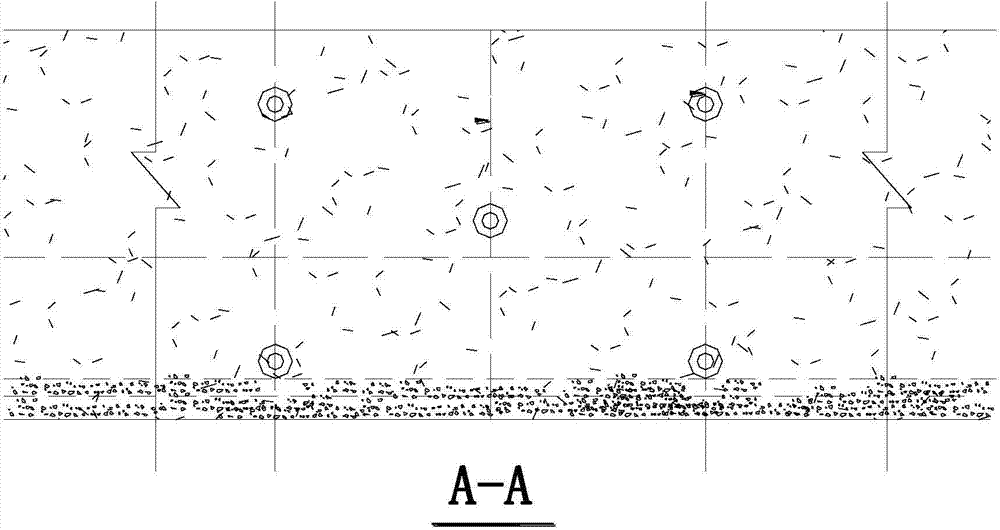

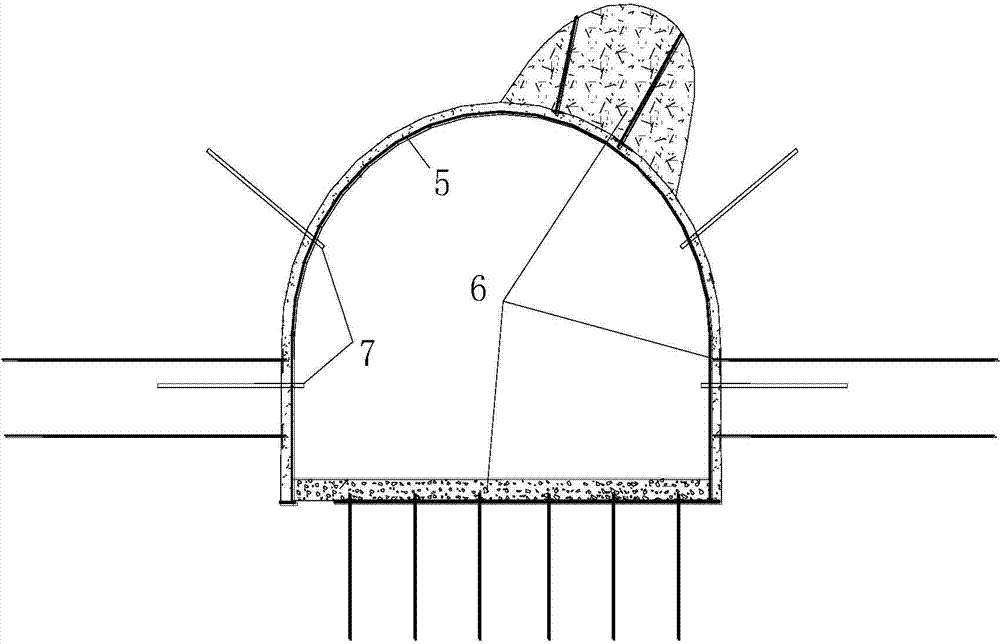

[0028] b. Install the flexible PPR deep hole grouting anchor rod 2 in the constructed deep grouting hole 3, the PPR deep hole grouting anchor rod used is 4m; use the grouting hole sealing device 4 to seal the hole, and seal the hole The anchoring force is not less than 60KN, and the grouting hole sealing device 4 is set at the peripheral position of the contour line of the original design section 5 of the roadway. After the grouting hole sealing device 4 is arranged, the full-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com