Packaging feeding machine of plastic injection molding products

A technology for injection molding products and feeders, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of pollution of injection molding products, low manual operation efficiency, and lack of suitable automatic transportation, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

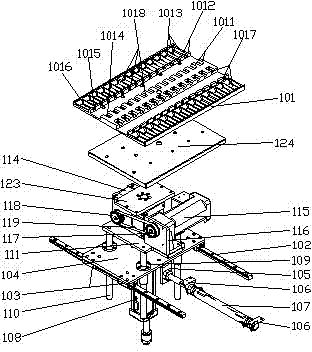

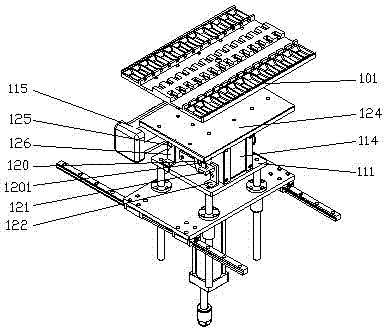

[0081] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. This embodiment is a packaging feeder for conveying plastic tableware.

[0082] 1. The general structure and working principle of the whole machine

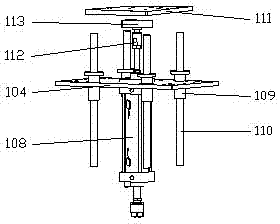

[0083] Such as figure 1As shown, the receiving mechanism 1 is installed in the middle of the feeder, the receiving translation device 11 is installed on the frame of the feeder, and the product loading plate 101 is installed on the receiving translation device 11 . The first retrieving mechanism 2 is installed on the upper left end of the feeder, the retrieving translation device 21 is installed on the frame, the retrieving lifting device 22 is installed on the retrieving translation device 21, and the retrieving gripper device 23 is installed on the reclaiming lifting device. On the device 22, a plurality of retrieving grippers 24 arranged in a row are arranged on the retrieving gripper device 23. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com