Filter tow packing machine and control method thereof

A control method and tow technology, applied in the field of tobacco production equipment, can solve the problems of different heights of tow packages, increased transportation costs, and impact on the transportation of tow packages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

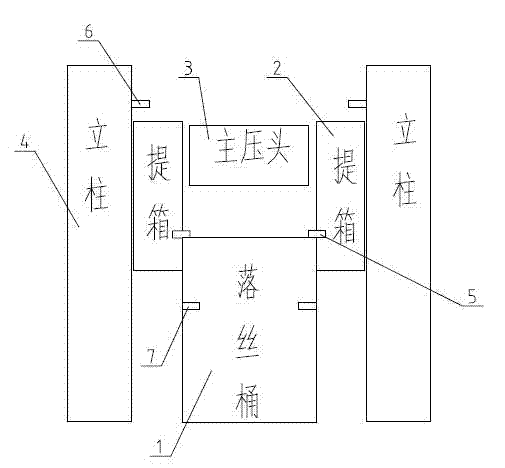

[0019] like figure 1 Shown: a tow baler, including a doffing barrel 1, a suitcase 2, a main pressure head 3, a column 4 and a power unit (not shown in the figure), the suitcase 2 is arranged on the column 4, and the The suitcase 2 can move up and down along the column 4, the doffing barrel 1 is arranged on the side of the suitcase 2 away from the column 4, and the doffing barrel 1 can be driven by the suitcase 2 to move along the column 4. Moving up and down, the doffing barrel 1 can also move horizontally along the direction perpendicular to the suitcase 2 and the column 4, the main pressure head 3 can move up and down along the direction of the upright 4, and the doffing barrel 1 , the movement of the suitcase 2 and the main pressure head 3 is driven by the power device, and also includes a controller (not shown in the figure), a doffing barrel position sensor 5, a suitcase position sensor 6 and the position of the main pressure head Sensor 7, the doffing barrel position se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com