Cartoned cigarette collecting machine

A technology of collecting machine and bar cigarette, which is applied in packaging automatic control, packaging, packaging protection and other directions, can solve the problems such as the impact of the lifting cam, the too fast action of the push plate, and the large impact of the lifting rod on the cam surface, so as to increase the conveying capacity. Friction, reduce the frequency of downtime, and solve the effect of rebound phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

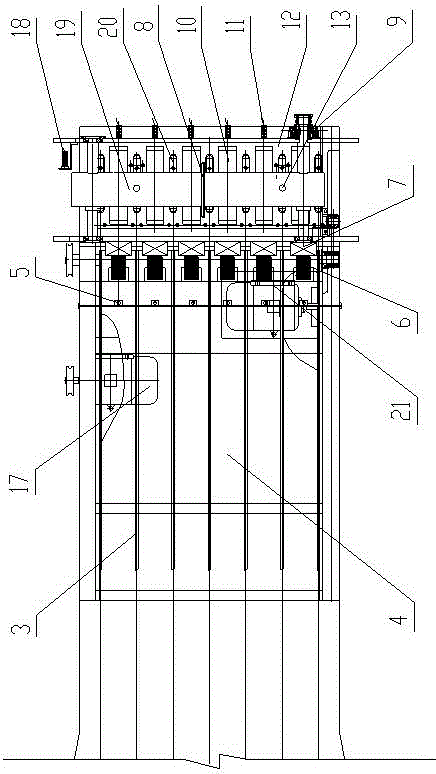

[0053] like figure 1 , 2 As shown, the present invention includes a cigarette sliding reversing bucket and a sliding channel 2 connected to the tail of the sliding reversing bucket, as well as a frame 22 and a conveying mechanism, a lifting mechanism, and a smoking conveying device installed on the frame 22. The lower end of the sliding channel 2 is connected with the frame 22 . A lifting mechanism is arranged at the outlet of the conveying mechanism, and a smoke removing conveying device is arranged above the lifting mechanism.

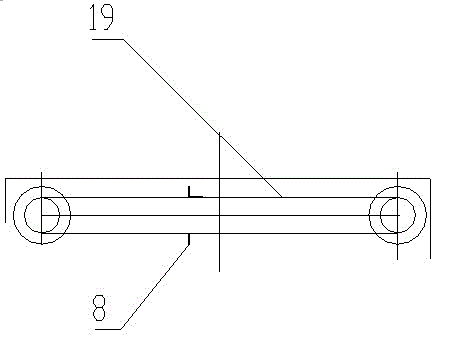

[0054] The conveying mechanism includes several guide rails 3 juxtaposed in parallel, a conveyor belt 4 located under the guide rails 3 and a brush 6 , and the brush 6 is located above the traveling end of the conveyor belt 4 . The conveyor belt 4 is driven by a conveyor belt motor 17 . The left end of the guide rail 3 is correspondingly connected with the lower end of the sliding channel 2 .

[0055] The lifting mechanism includes a lifting moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com