Method for assembling nano-particles carrying laminin and SDF-1alpha on surfaces of Ti materials

A technology of laminin and SDF-1, which is applied to devices for coating liquids on surfaces, special surfaces, coatings, etc., can solve the problems of insufficient blood compatibility, limited application, etc., and achieve a simple preparation process and fixation method. Easy to operate, inhibit thrombosis, inhibit the effect of smooth muscle hyperplasia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

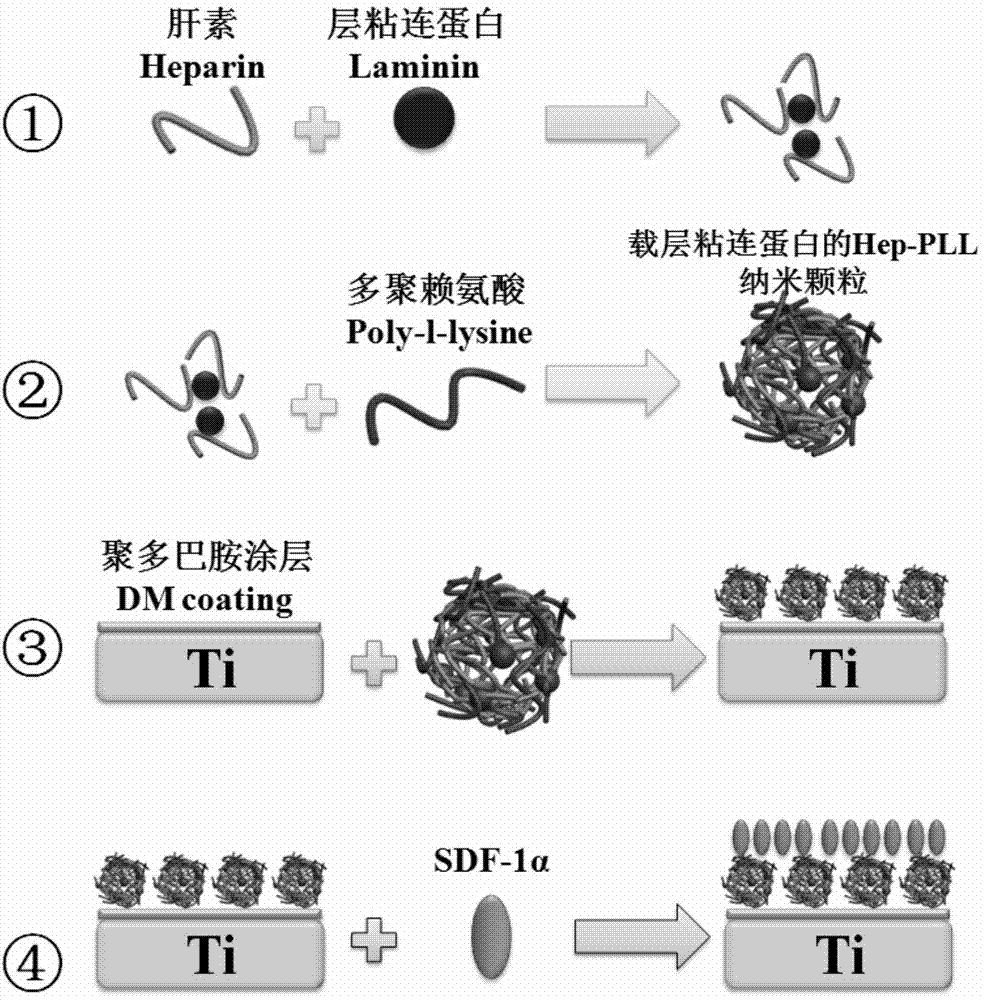

[0026] see figure 1 , the first embodiment of the present invention is a method for loading laminin nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0027] A, polydopamine is deposited on the surface of cardiovascular metal Ti material to deposit polydopamine coating, and dry at 37°C;

[0028] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 30 μg / ml to a heparin sodium solution with a concentration of 10 mg / ml, and let stand at 37°C for 1 hour; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 0.3mg / ml;

[0029] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 50°C for 24 hours, and wash with phosphate buffered saline (PBS) and double distilled water...

Embodiment 2

[0032] A method for loading laminin-loaded nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0033] A, polydopamine is deposited on the surface of the metal Ti material to deposit a polydopamine coating, and dry at 37 ° C;

[0034] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 300 μg / ml to a heparin sodium solution with a concentration of 30 mg / ml, and let stand at 37°C for 3 hours; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 1.0mg / ml;

[0035] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 15°C for 6 hours, and wash with phosphate buffered saline (PBS) and double distilled water respectively Rinse and save for later use;

[0036] D. Assemb...

Embodiment 3

[0038] A method for loading laminin-loaded nanoparticles and SDF-1α on the surface of a Ti material, the steps of which are:

[0039] A, polydopamine is deposited on the surface of the metal Ti material to deposit a polydopamine coating, and dry at 37 ° C;

[0040] B. Preparation of laminin-loaded nanoparticles Add an equal volume of laminin solution with a concentration of 200 μg / ml to a heparin sodium solution with a concentration of 20 mg / ml, and let stand at 37°C for 2 hours; Under stirring conditions, add an equal volume of heparin sodium and laminin mixture dropwise to a polylysine (PLL, MW150-300KDa) solution with a concentration of 0.5mg / ml;

[0041] C. Nanoparticle immobilization Soak the sample deposited with polydopamine in step A in the nanoparticle suspension obtained in step B, react under shaking conditions at 37°C for 12 hours, and wash with phosphate buffered saline (PBS) and double distilled water respectively Rinse and save for later use;

[0042] D. Assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com