Rotating-shaft-type baked wheat cake furnace

A biscuit oven and rotating shaft technology, applied in food ovens, climate change adaptation, baking, etc., can solve the problems of unpopularity, high carbon consumption, and no flavor of biscuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

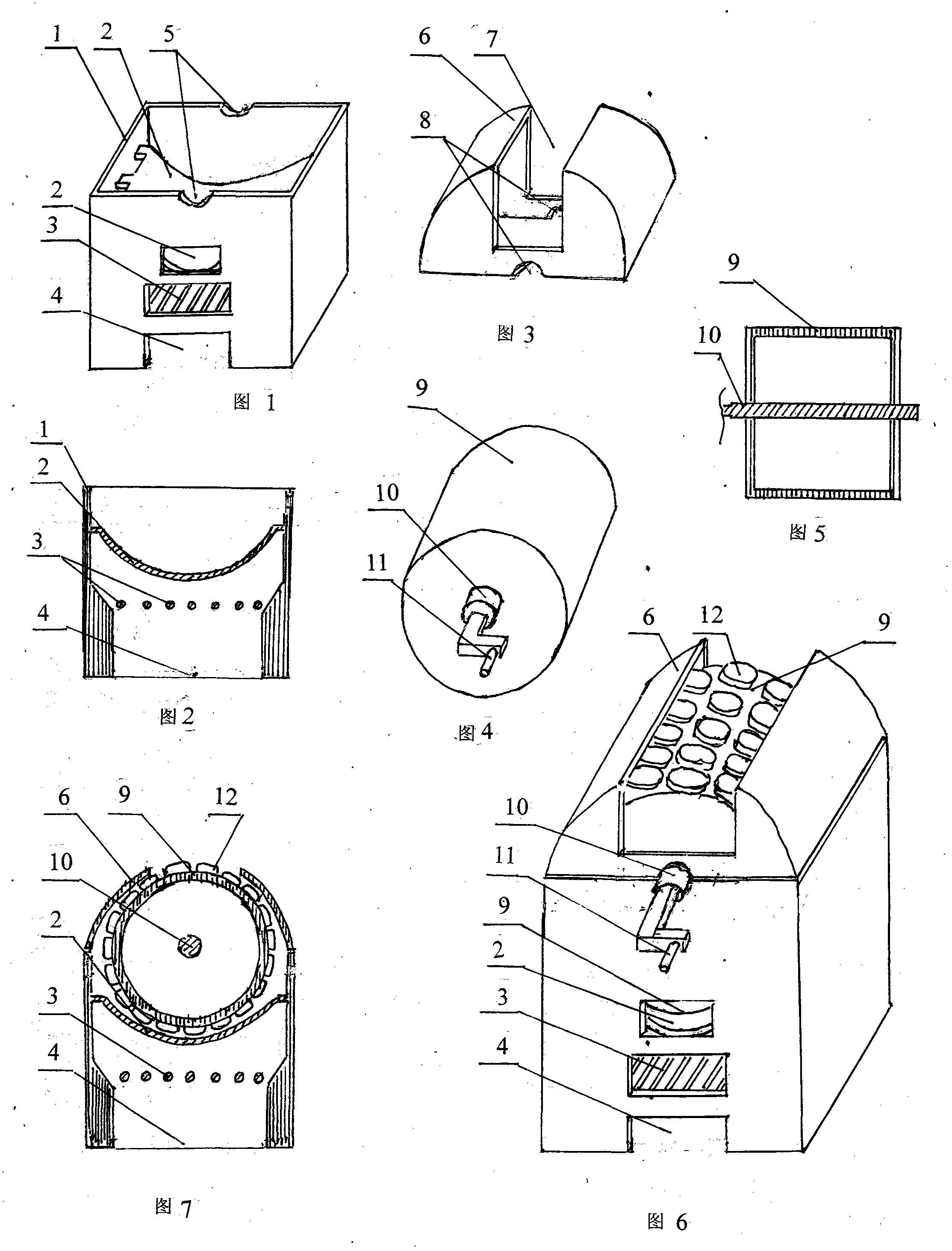

[0006] Such as Image 6 Shown, first Figure 4 The shown baking shaft is placed on the shaft opening 5 of the upper opening of the furnace body through the two ends of the force shaft 10, and then image 3 The stove hood shown is buckled on the upper mouth of the stove body, so that part of the baked veneer 9 on the baking shaft is exposed at the U-shaped notch 7 of the stove hood. After pasting the raw cake on the baking veneer 9, shake the handle 11 Put the raw cake 12 into the cavity of the furnace, and finally remove the cooked cake from the U-shaped gap and paste the raw cake, and the operation is repeated. If any cooked cake falls off on the picking plate 2, it can be picked out from the picking opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com