Production system and production method of optical display device

An optical display and production system technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy dust adhesion and poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

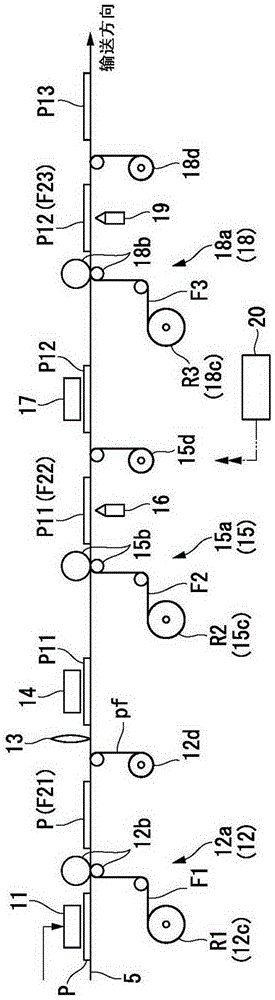

[0047] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. In this embodiment, as a production system of an optical display device, a film bonding system constituting a part thereof will be described.

[0048] In particular, as described in detail below, in the film bonding system of the first embodiment, the bonding devices 12, 15, 18 and the cutting devices 16, 19 are arranged below the roller conveyor 5 (line), The cutting device 13 is arranged above the roller conveyor 5 .

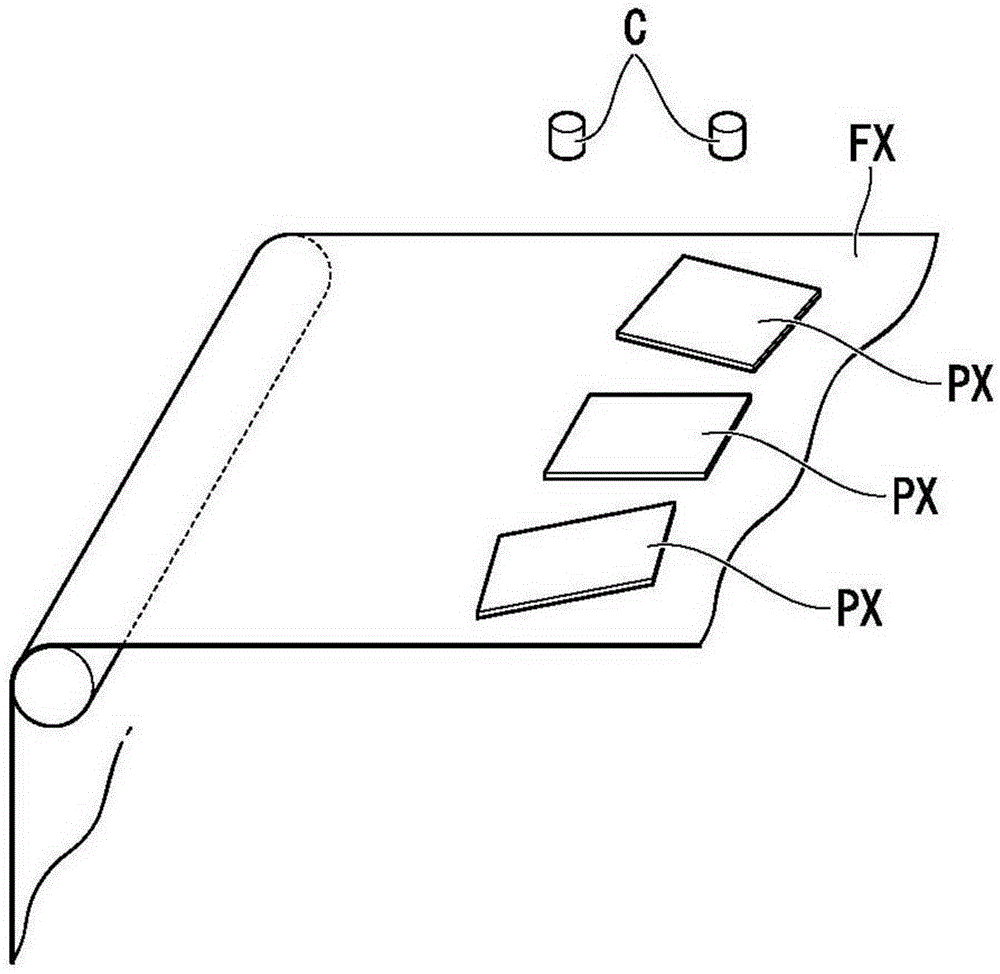

[0049] figure 1 It shows the schematic structure of the film bonding system 1 of this embodiment. The film bonding system 1 bonds film-shaped optical members such as polarizing films, retardation films, and brightness enhancement films to panel-shaped optical display components such as liquid crystal panels and organic EL panels. The film bonding system 1 manufactures the optical member bonding body containing the said optical display component ...

no. 2 approach )

[0115] Hereinafter, a second embodiment of the present invention will be described with reference to the drawings. In this embodiment, as a production system of an optical display device, a film bonding system constituting a part thereof will be described.

[0116] In the second embodiment, the same symbols are assigned to the same components as those in the first embodiment, and descriptions thereof are omitted or simplified.

[0117] In particular, as described in detail below, in the film bonding system of the second embodiment, the bonding devices 112, 115, 118 and the cutting devices 116, 119 are arranged on the roller conveyor 105, and the cutting device 113 It is arranged under the roller conveyor 105 .

[0118] Figure 13 It shows the schematic structure of the film bonding system 101 of this embodiment. The film bonding system 101 bonds a film-shaped optical member such as a polarizing film, a retardation film, or a brightness enhancement film to a panel-shaped opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com