Sintering machine production increase modification system and process

A sintering machine and machine head technology, which is applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems such as the difficulty of passing the audit of the environmental protection department, the unsuitable modification of the desulfurization system, and the difficulty in achieving the purpose of increasing production. Reduce solid fuel consumption, low renovation cost, and improve the effect of negative air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

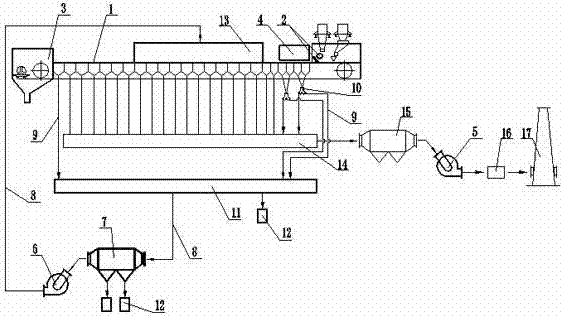

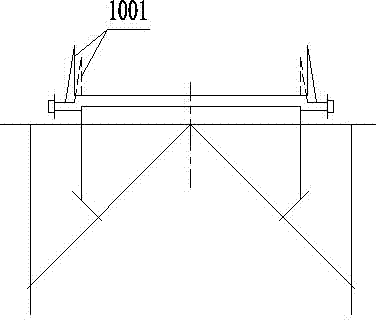

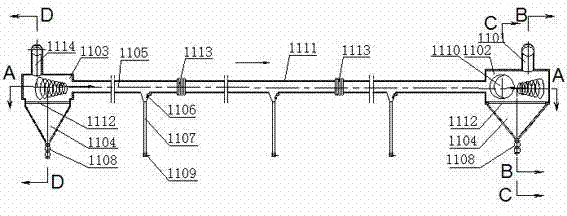

[0031] Such as figure 1 As shown, a sintering machine production increase reconstruction system includes a sintering machine trolley 1, a feeding device 2 arranged at the front end of the trolley 1, an ignition furnace 4, a discharge device 3 arranged at the rear end of the trolley 1, and a 1 A plurality of sintering bellows at the bottom, a main flue 14 connected to each sintering bellows, a main electrostatic precipitator 15 connected to the outlet of the main flue 14, a main exhaust fan 5 connected to the outlet of the main electrostatic precipitator 15, and a main exhaust fan 5 connected to the main The flue gas desulfurization equipment 16 and the chimney 17 at the outlet of the exhaust fan 5, in addition, a flue gas circulation system is added. The flue gas circulation system consists of a collection and discharge pipeline 11 connected to the sintering machine head and tail bellows respectively by means of a circulation branch pipe 9, a circulation main pipeline 8 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com