High-efficiency catalytic combustion device and combustion method for low-concentration methane containing dust and sulfur

A catalytic combustion, low-concentration technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of catalyst activity regeneration purging, complex removal process, impurity gas removal and catalytic combustion cannot be realized , to achieve the effect of full energy utilization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

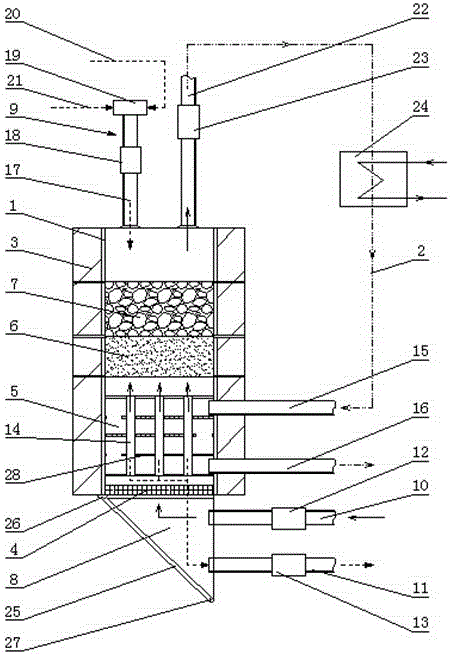

[0029] Such as figure 1 As shown, the high-efficiency catalytic combustion device for dust-containing, sulfur-containing and low-concentration methane includes a combustion cylinder 1 and a flue gas circulation preheating unit 2 . An insulating layer 3 is provided on the outer wall of the combustion tube 1, and a dust removal plate 4, a preheating chamber 5, a desulfurization adsorption layer 6 and a catalytic combustion layer 7 are sequentially arranged in the combustion tube 1 from bottom to top. An air intake cavity 8 is arranged below the combustion cylinder 1 , and a reverse gas purging unit 9 is arranged above the combustion cylinder 1 .

[0030] Among them, a low-concentration methane inlet pipe 10 and a purge gas discharge pipe 11 are arranged on the side wall of the air intake chamber 8, a solenoid valve I12 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com