Tamper hydraulic system and construction machinery

A technology of hydraulic system and rammer, which is applied in the direction of mechanical equipment, infrastructure engineering, fluid pressure actuation device, etc., can solve the problems of hammering efficiency drop, difficulty in controlling lifting oil pressure release time, slow pressure drop, etc., to achieve reduction The effect of hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

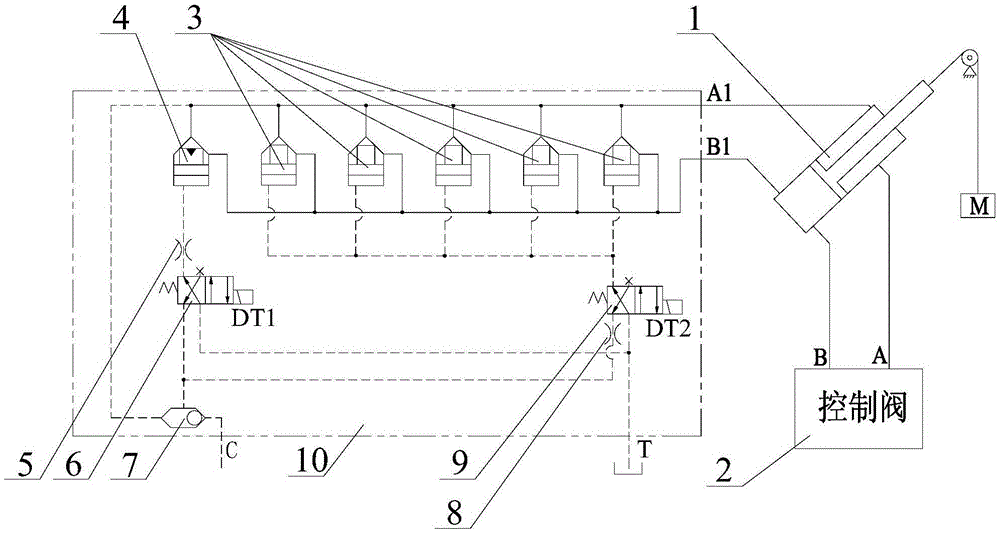

[0040] Please also refer to Figure 2 to Figure 5 , the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

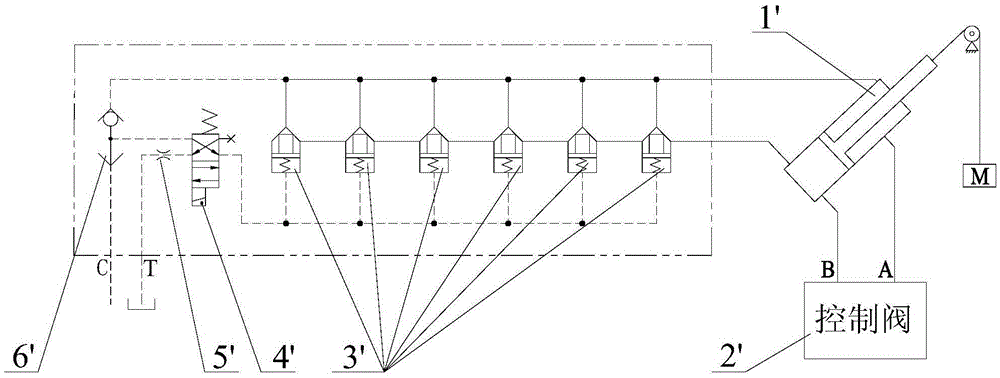

[0041] combine figure 2 As shown, the tamper hydraulic system of the first embodiment includes a lift cylinder 1, a control valve 2, a switch cartridge valve 3, a buffer cartridge valve 4, a first damper 5, a second reversing valve 6, a shuttle valve 7, a second Two dampers 8, the first reversing valve 9 and the oil tank.

[0042] Among them, the working oil ports A and B of the control valve 2 are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com