A method for preparing dry pu/pvdf hydrophobic polyurethane coating for synthetic leather

A polyurethane coating and synthetic leather technology, applied in the direction of polyurea/polyurethane coatings, synthetic resin layered products, coatings, etc., can solve the problems of poor hydrophobic performance and anti-pollution performance, unfavorable industrial production and economic benefits, and high industrial costs. problems, to achieve the effect of large value, good piezoelectricity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing synthetic leather with dry process PU / PVDF hydrophobic polyurethane coating, comprises the following steps:

[0022] 1) First mix HDS-50HF polyurethane PU and polyvinylidene fluoride PVDF according to the mass fraction ratio of 100:5;

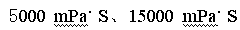

[0023] 2) Add nitrogen nitrogen dimethylformamide DMF: acetone MEK = 40:20 mass parts solvent, the solvent includes dimethyl formamide DMF and acetone MEK, disperse the two in the organic solvent, and then add mass parts It is 15 parts of color paste auxiliary materials, configured as a surface layer; also configured according to the ratio of HDA-20 polyurethane PU: nitrogen nitrogen dimethyl formamide DMF: acetone MEK: color paste = 100:20:20:15 For the adhesive layer, the surface layer slurry and the adhesive layer fabric were fully stirred with a vacuum mixer at room temperature for 2 hours, so that their viscosities were respectively at , using a vacuum machine to vacuumize the modified solution for degassing...

Embodiment 2

[0026] A method for preparing synthetic leather with dry process PU / PVDF hydrophobic polyurethane coating, comprises the following steps:

[0027] 1) First mix HDS-50HF polyurethane PU resin and polyvinylidene fluoride PVDF according to the mass fraction ratio of 100:10;

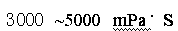

[0028] 2) Add nitrogen nitrogen dimethylformamide DMF: acetone MEK=40:20 solvent in parts by mass, the solvent includes dimethylformamide DMF and acetone MEK, disperse the two in the organic solvent, and then add mass parts 15 parts of color paste and other auxiliary auxiliary materials are configured as a surface layer; also configured as a bonding agent according to the ratio of polyurethane PU: nitrogen nitrogen dimethyl formamide DMF: acetone MEK: color paste = 100:20:20:15 layer, the surface layer slurry and the adhesive layer fabric were fully stirred at room temperature with a vacuum mixer for 2 hours, so that their viscosities were respectively at , using a vacuum machine to vacuumize the modified ...

Embodiment 3

[0031] A method for preparing synthetic leather with dry process PU / PVDF hydrophobic polyurethane coating, comprises the following steps:

[0032] 1) First, mix HDS-50HF polyurethane PU and polyvinylidene fluoride PVDF according to the mass fraction ratio of 100:15. When the ratio of PU to PVDF exceeds 100:15, the film will become hard and brittle, which is not conducive to synthetic leather. ;

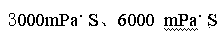

[0033] 2) Add nitrogen nitrogen dimethylformamide DMF: acetone MEK = 40:20 mass parts solvent, the solvent includes dimethyl formamide DMF and acetone MEK, disperse the two in the organic solvent, and then add mass parts It is 15 parts of color paste and other auxiliary materials, configured as a surface layer; also configured according to the ratio of HDA-20 polyurethane PU: nitrogen nitrogen dimethyl formamide DMF: acetone MEK: color paste = 100:20:20:15 To form a cohesive layer, the surface layer slurry and the cohesive layer fabric were fully stirred with a vacuum mixer at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com