Sizing bucket of CNC sizing machine

A technology of sizing barrel and sizing machine, which is applied in the field of sizing barrel, can solve the problems of production cost, sizing quality, and weaving quality, and achieve the effects of scientific design, unstable sizing quality, and accurate ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below.

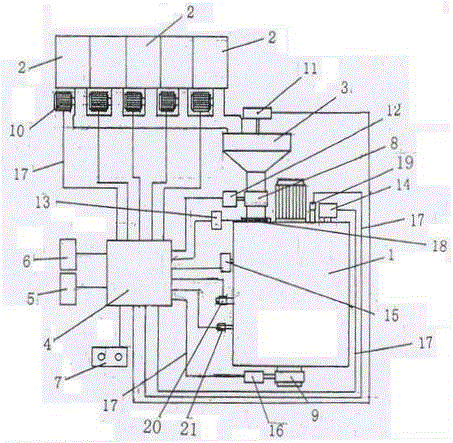

[0018] As shown in the figure, the sizing barrel of the CNC sizing machine is equipped with a weighing funnel 3 for feeding materials on the barrel body 1. The weighing funnel 3 is connected to several feeding boxes 2 through the feeding pipe, and the feeding box 2 The motors 10 are connected to the single-chip microcomputer 4 through wires 17 respectively. The weighing funnel 3 is connected with the single-chip microcomputer 4 through the weighing sensor 11 . A feed valve sensor 12 is provided on the feed valve 8 where the barrel body 1 is connected with the weighing funnel 3 , and the feed valve sensor 12 and the feed valve 8 are connected with the single-chip microcomputer 4 . A pulp bucket cover valve sensor 13 and a pulp bucket cover valve 18 are equipped with on the staving 1 top, and the pulp bucket cover valve sensor 13 and the pulp bucket cover valve 18 are connected with the single-chip mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com