Color reflective heat-insulation exterior wall elastic coating and preparation method thereof

An elastic coating and reflective technology, applied in the field of coatings, can solve the problems of poor elasticity and single color of thermal insulation coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

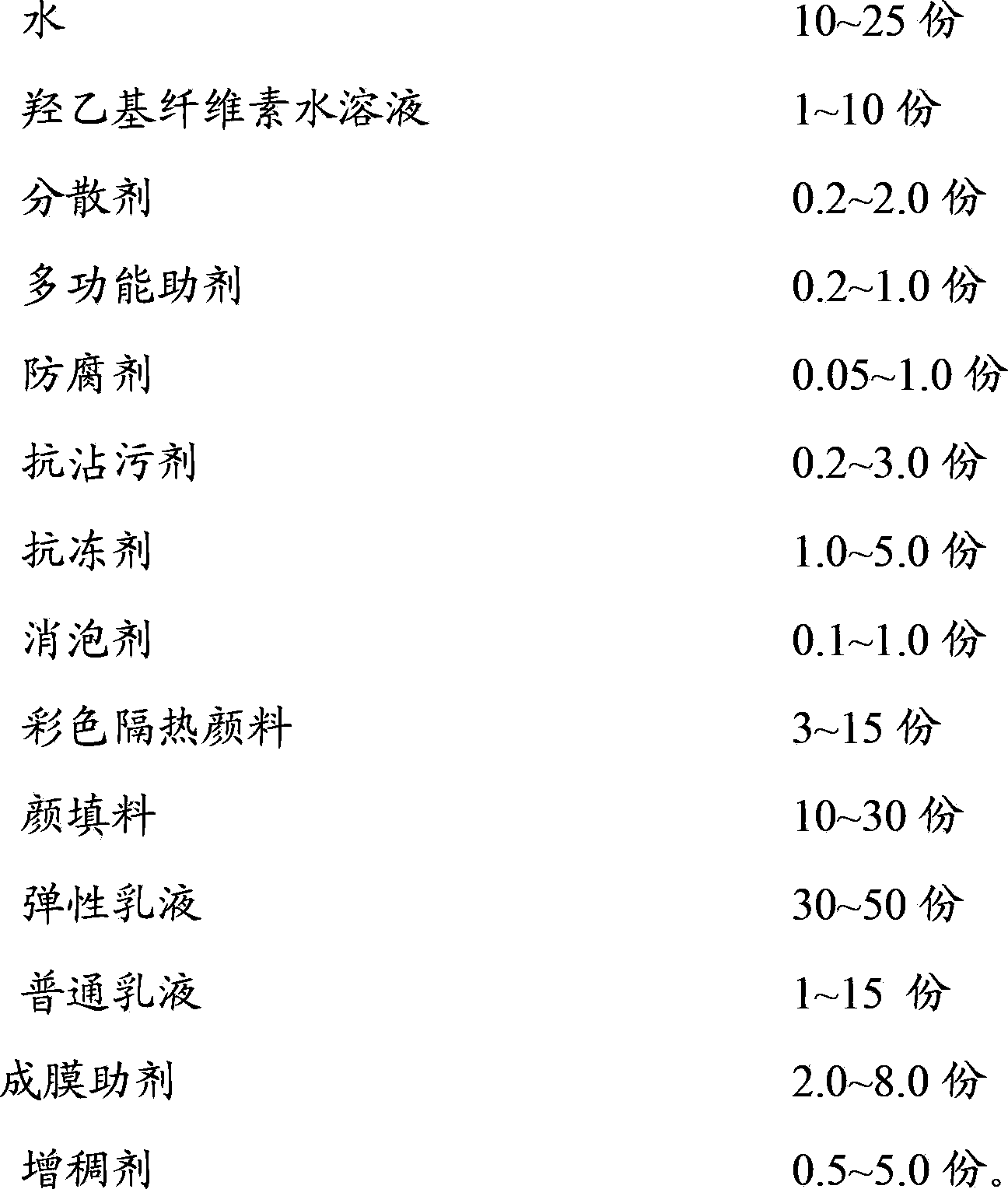

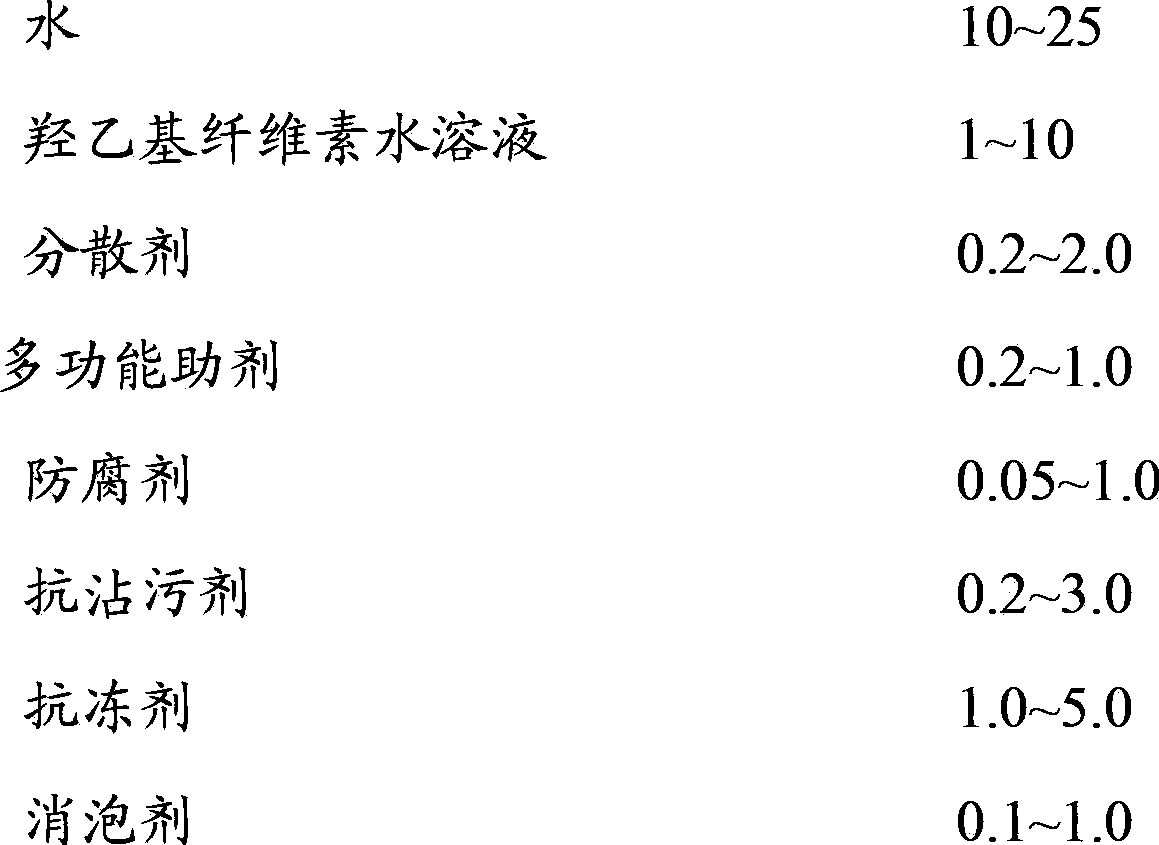

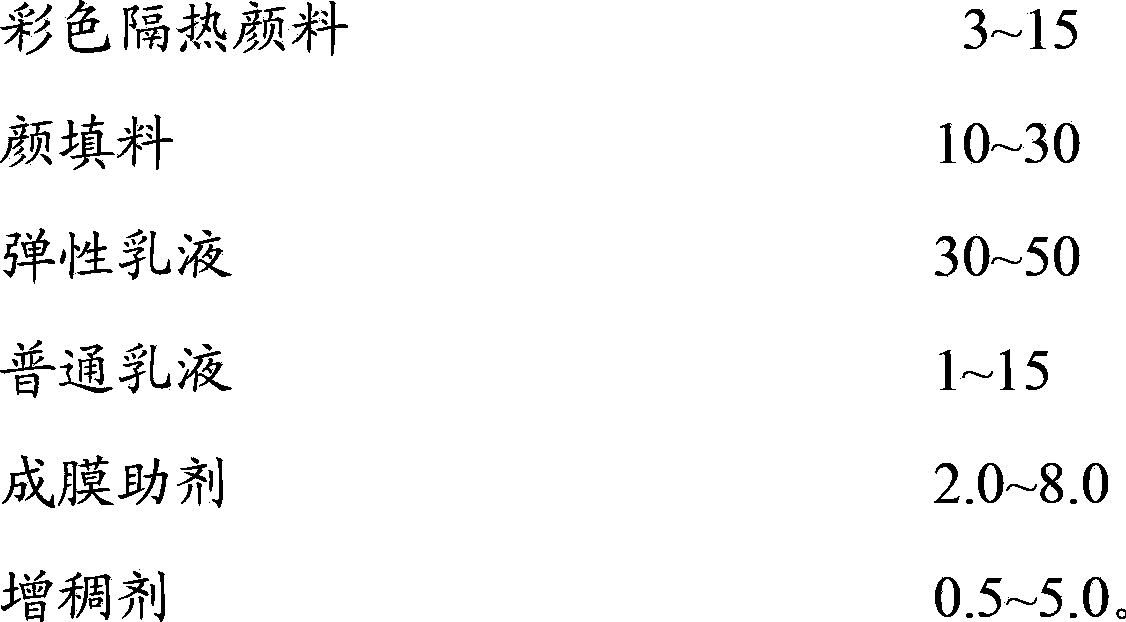

[0022] Embodiments of the present invention further provide a method for preparing the above-mentioned colored reflective elastic coating for heat-insulating exterior walls, which includes the following steps:

[0023] Step S01, preparing the first mixture:

[0024] Add 15~25 parts of water to the container, and add 1.0~10.0 parts of hydroxyethyl cellulose aqueous solution, 0.2~2 parts of dispersant, 0.2~1.0 parts of multifunctional additives, 0.05~ 1.0 part preservative, 0.2~3.0 part anti-fouling agent, 1.0~5.0 part antifreeze and 0.1~0.5 part defoamer, the time interval between adding each two components is 2~10 minutes;

[0025] Step S02, preparing a second mixture:

[0026] Adjust the rotation speed to 1000~1500rpm, add 3~15 parts of color heat insulating pigments and 10~30 parts of pigments and fillers, and stir for 5~60 minutes;

[0027] Step S03, preparing a third mixture:

[0028] Adjust the speed to 800~1200rpm, add 30~50 parts of elastic emulsion, 1~15 parts of or...

Embodiment 1

[0038] Example 1 (brown)

[0039]Add 18 parts of water to the paint tank, adjust the speed to 500rpm, add 3 parts of 2% HEC aqueous solution, 0.6 parts of dispersant KPA, 0.2 parts of multifunctional additive AMP-95, 0.2 parts of preservative NipacideDFX / 1, 0.5 parts of anti-fouling agent SRC-220, 1.0 parts of antifreeze propylene glycol (industrial grade) and 0.2 parts of defoamer BYK-024, each component is added to disperse for 3 minutes; adjust the speed to 1500rpm, add 5 parts of color insulation Pigment Brown 20C819 (Schete), 8 parts of rutile titanium dioxide R706, 15 parts of 1250 mesh heavy calcium powder, 6 parts of 1250 mesh kaolin, disperse at high speed for 30 minutes; adjust the speed to 800rpm, add 35 parts of elastic emulsion 9389 (BATF ), 5 parts of pure acrylic emulsion 2806 (BATF), and then add 1.2 parts of film-forming aid alcohol fat 12 and 0.4 parts of defoamer BYK024 after 5 minutes; finally adjust the speed to 600rpm and add 0.5 parts of thickener ASE-60...

Embodiment 2

[0040] Example 2 (yellow)

[0041] Add 20 parts of water to the paint tank, adjust the speed to 500rpm, add 2.0 parts of 5% HEC aqueous solution, 0.8 parts of dispersant BYK-191, 0.3 parts of multifunctional additive DeuAdd MA-95, and 0.1 parts of preservative V698K1, 1.0 parts of anti-fouling agent SRC-220, 1.0 parts of antifreeze propylene glycol (industrial grade) and 0.3 parts of defoamer BYK-024, disperse each component for 3 minutes; adjust the speed to 1500rpm, add 10 parts of color Heat-insulating pigment Yello10C112 (Schete), 6 parts of rutile titanium dioxide R244, 10 parts of 1250 mesh heavy calcium powder, 4 parts of 1250 mesh kaolin, 5 parts of barite powder 10HB (nano powder), high-speed dispersion for 30 minutes; Adjust to 800rpm, add 37 parts of elastic emulsion 2438M in turn, and then add 1.5 parts of film-forming aid alcohol fat 12, 0.3 parts of defoamer BYK-021 in turn after 5 minutes; finally adjust the speed to 600rpm, add 0.6 parts of thickener TT -935,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com