Cold ceramic glaze with sterilization and antibacterial functions and preparation method thereof

A ceramic and functional technology, applied in the field of ceramic cold glaze and its preparation, can solve the problems of not being able to effectively save energy and reduce fuel consumption, and achieve the effects of good blank glaze adaptability, energy saving, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

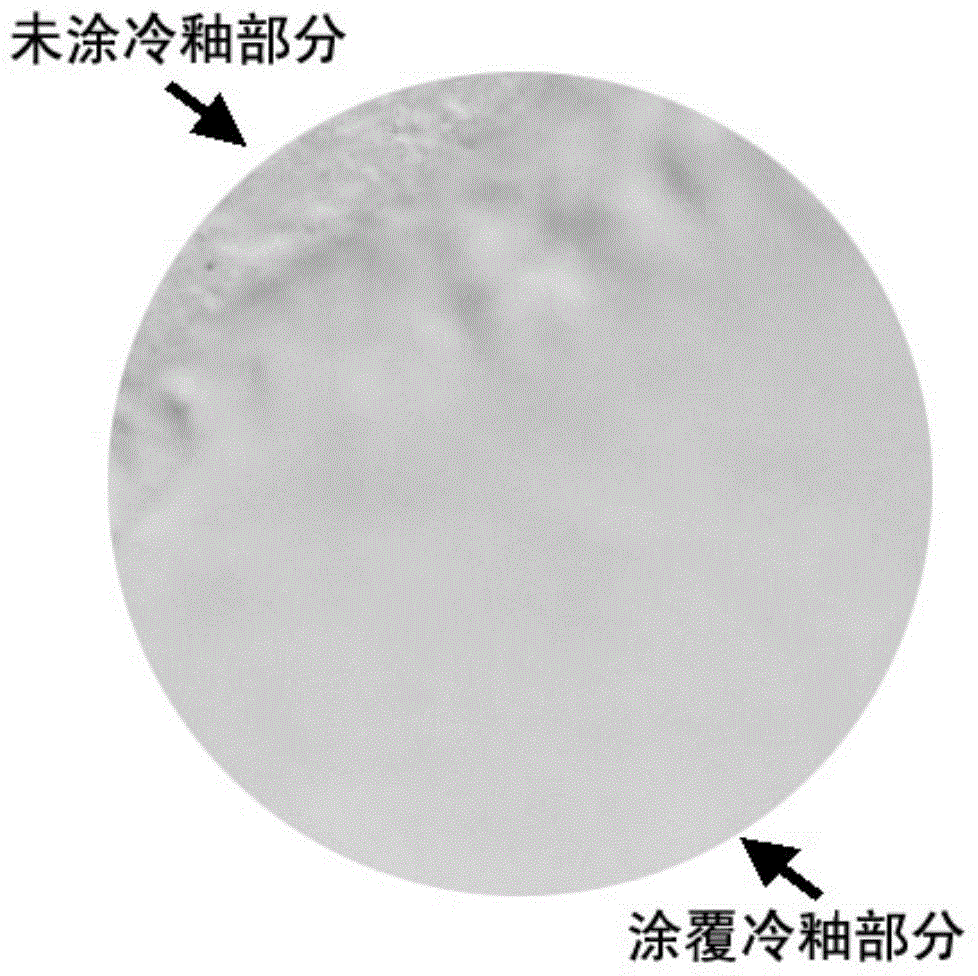

Image

Examples

Embodiment 1

[0023] A kind of ceramic cold glaze with antibacterial, degerming function, its preparation method comprises the steps:

[0024] (1) In parts by weight, prepare 1 part of tetrabutyl titanate, 1 part of ethyl orthosilicate, 1 part of absolute ethanol, 1 part of 200 mesh metakaolin, 1 part of 300 mesh alumina, and the modulus is 1 part of water glass solution of 3, 0.5 part of sodium hydroxide, and 1 part of water;

[0025] (2) Mix tetrabutyl titanate, ethyl orthosilicate and absolute ethanol prepared in step (1), and stir with a mechanical stirrer for 2 hours to obtain a premixed solution;

[0026] (3) Add metakaolin, alumina, water glass, sodium hydroxide, water successively to the premixed liquid, and mix for 2 hours under stirring with a mechanical stirrer to form a mixed slurry;

[0027] (4) Brush the mixed slurry on the ceramic body to be decorated, place it at room temperature for 3 days to dry, and the ceramic cold glaze is formed on the surface of the ceramic body.

...

Embodiment 2

[0033] A kind of ceramic cold glaze with antibacterial, degerming function, its preparation method comprises the steps:

[0034] (1) In parts by weight, prepare 1 part of tetrabutyl titanate, 8 parts of ethyl orthosilicate, 4 parts of absolute ethanol, 3 parts of 250 mesh metakaolin, 4 parts of 300 mesh alumina, and the modulus is 3, 2 parts of water glass solution, 1 part of sodium hydroxide, 5 parts of water;

[0035] (2) Mix tetrabutyl titanate, ethyl orthosilicate and absolute ethanol prepared in step (1), and stir with a mechanical stirrer for 3 hours to obtain a premixed solution;

[0036] (3) Add metakaolin, aluminum oxide, water glass, sodium hydroxide, water successively to the premixed liquid, and mix for 3 hours under stirring with a mechanical stirrer to form a mixed slurry;

[0037] (4) Apply the mixed slurry to the ceramic body to be decorated, and place it in a curing box at 60° C. for 2 days, and the ceramic cold glaze is formed on the surface of the ceramic b...

Embodiment 3

[0043] A kind of ceramic cold glaze with antibacterial, degerming function, its preparation method comprises the steps:

[0044] (1) In parts by weight, prepare 8 parts of tetrabutyl titanate, 8 parts of ethyl orthosilicate, 8 parts of dehydrated alcohol, 4 parts of 250 mesh metakaolin, 4 parts of 300 mesh alumina, and the modulus is 3 parts of water glass solution, 2 parts of sodium hydroxide, and 10 parts of water;

[0045] (2) Mix tetrabutyl titanate, ethyl orthosilicate and absolute ethanol prepared in step (1), and stir with a mechanical stirrer for 2.5 hours to obtain a premixed solution;

[0046](3) Add metakaolin, aluminum oxide, water glass, sodium hydroxide, water successively to the premixed liquid, and mix for 3 hours under stirring with a mechanical stirrer to form a mixed slurry;

[0047] (4) Apply the mixed slurry to the ceramic body to be decorated, and place it in a curing box at 80° C. for 2 days, and the ceramic cold glaze is formed on the surface of the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com