Method for coagulation-ion exchange-coagulation circulating reflux treatment of secondary effluent

A technology of secondary effluent and ion exchange, applied in ion exchange water/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc. Dosage and other issues to achieve the effect of improving flocculation effect, improving efficiency and reducing turbidity of effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

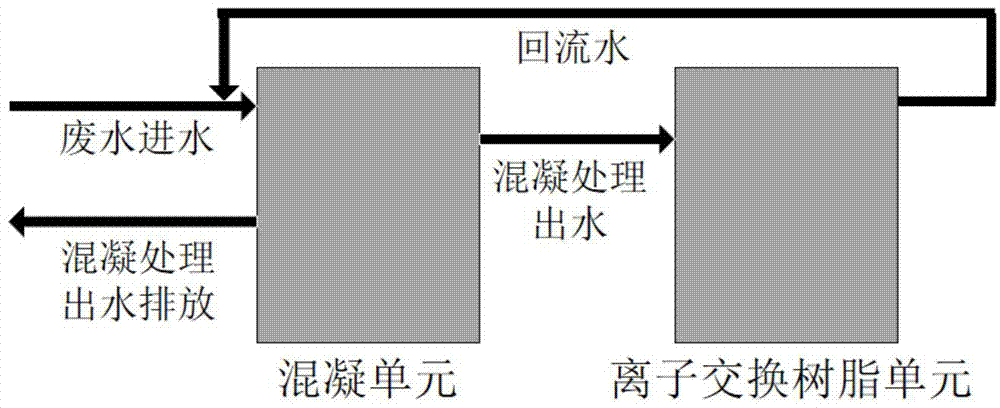

[0029] Such as figure 1 The flow chart of the influent and effluent water of the medium coagulation-ion exchange-coagulation treatment process is shown: a secondary biochemical treatment system using anaerobic, anoxic, and aerobic microorganisms is used, and the effluent enters the coagulation unit. Cr Add 0.06g of polyaluminum chloride, stir at 100rpm for 2min, then reduce the stirring speed to 25rpm, continue stirring for 35min and then stop. After the flocs settle for 90min, discharge all the treated effluent into the anion exchange resin unit; coagulate effluent and D201 The anion exchange resin (see Table 1) reacts; the wastewater treated by the ion exchange resin unit is refluxed to the coagulation unit at a reflux ratio of 50%. Cr Add 0.06g of polyaluminum chloride, stir at 100rpm for 2min, then reduce the stirring speed to 25rpm, continue stirring for 35min and then stop. After the flocs settle for 90min, discharge all the treated effluent to other process sections, su...

Embodiment 2

[0033] Such as figure 1 The flow chart of the influent and effluent water in the medium coagulation-ion exchange-coagulation treatment process is shown: a secondary biochemical treatment system using anoxic, anoxic, and aerobic microorganisms is used, and the effluent enters the coagulation unit, according to the proportion per gram COD Cr Add 0.05g polyferric chloride, 0.004g / gCOD Cr Polyacrylamide (here expressed per gram of COD Cr Add 0.004g polyacrylamide (the same below), stir at 120rpm for 3min, then reduce the stirring speed to 30rpm, continue stirring for 40min and stop, after the flocs settle for 60min, discharge all the treated water into the anion exchange resin unit ; The coagulation effluent reacts with D213 anion exchange resin (see Table 1); the wastewater treated by the ion exchange resin unit is returned to the coagulation unit at a reflux ratio of 70%, and is treated according to the same coagulation conditions as mentioned above, and all of them are treate...

Embodiment 3

[0037] Such as figure 1 The flow chart of the influent and effluent water of the medium coagulation-ion exchange-coagulation treatment process is shown: a secondary biochemical treatment system using anoxic and aerobic microorganisms is used, and the effluent enters the coagulation unit, according to 0.15g / gCOD Cr Add polyaluminum ferric sulfate, stir at 110rpm for 2min, then reduce the stirring speed to 21rpm, continue stirring for 30min and then stop. After the flocs settle for 80min, discharge all the treated effluent into the anion exchange resin unit; the coagulation effluent is exchanged with D320 anion The resin (see Table 1) reacts; the wastewater treated by the ion exchange resin unit is refluxed to the coagulation unit at a reflux ratio of 95%, treated according to the same coagulation conditions as described above, and all the treated wastewater is discharged. This process has a chroma removal rate of 86%, COD Cr The removal rate is 68%, BOD 5 The removal rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com