Inverted umbrella-shaped impeller

An inverted umbrella type, impeller technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of large oxygen diffusion resistance and different oxygenation capacity, and achieve mixing and stirring. Uniform, complete oxygenation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

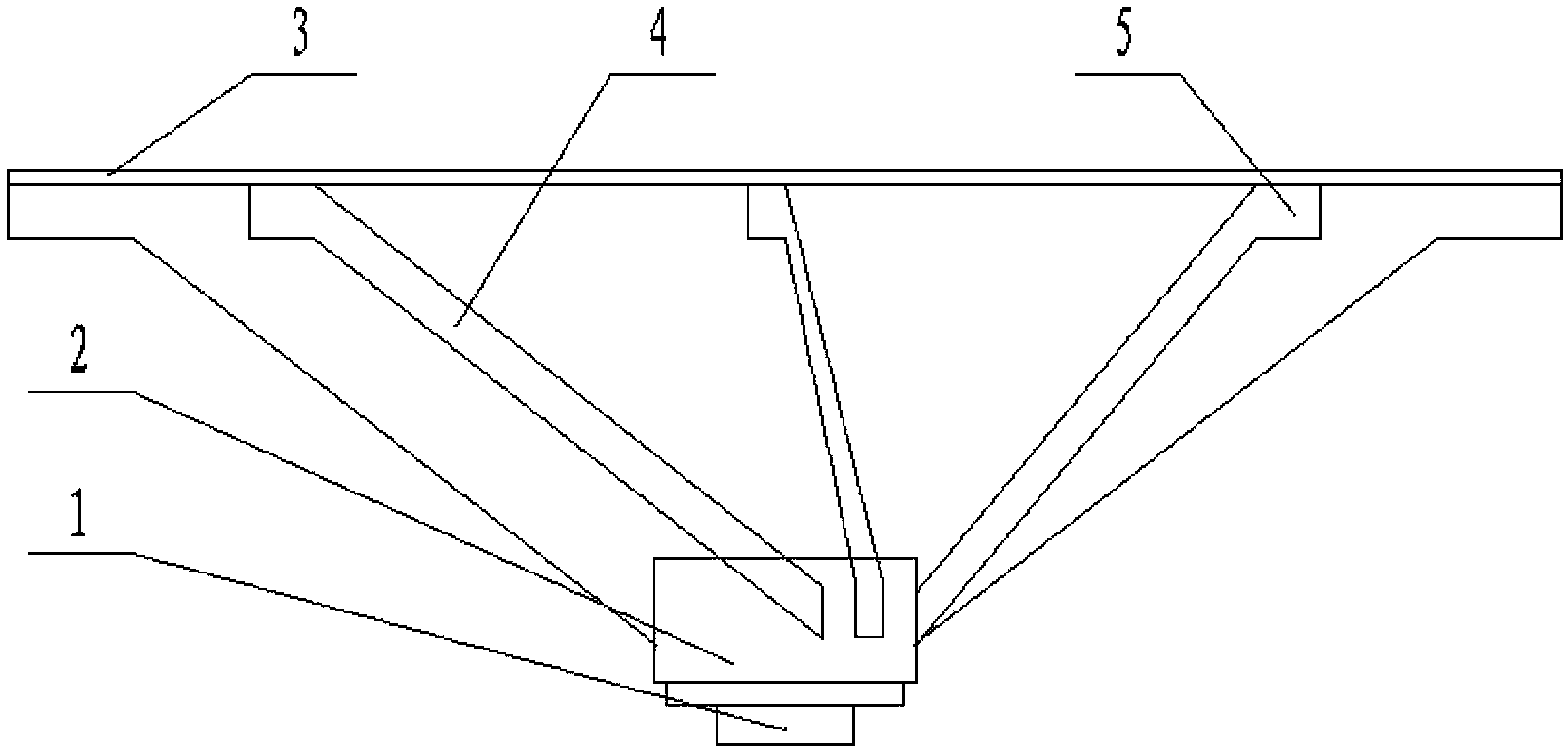

[0010] Such as figure 1 and figure 2 As shown, the inverted umbrella impeller includes a rotating shaft 1, a rotating shaft sleeve body 2, an annular flat plate 3, an umbrella rib blade 4, and an umbrella surface blade 5. The rotating shaft 1 is connected to the rotating shaft sleeve body 2, and the rotating shaft 1 is connected to the annular panel. The annular panel is connected to the The umbrella blades 5 are connected, the annular panel is connected with the rotating shaft 1, the umbrella rib blade 4 is connected with the umbrella surface blade 5, the umbrella rib blade 4 is connected with the rotating shaft 1, the rotating shaft 1 is connected with the rotating shaft sleeve body 2 by the connection mode selection key, and the annular panel is connected with the rotating shaft 1 The connection selects the sleeve key connection, the umbre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com