Mechanical cover distribution device

A cover separation and mechanical technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of poor quality of the manual cover separation system, and achieve the effects of uniform force, broad market prospects, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the drawings and embodiments.

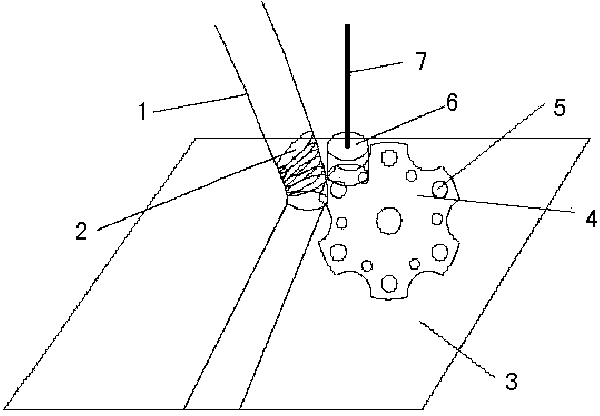

[0012] A mechanical lid separating device includes a guide lid cage 1, a lid 2, a base 3, a rotating disk 4, a lid drop hole 5, a lid separating device 6 and a rotating shaft 7. A guide lid cage 1 is installed on the base 3, The hollow cylindrical structure can be placed in the lid 2 in batches. The lid 2 is placed in the guide lid cage 1, and the lid divider 6 is provided next to the guide lid cage 1. The lid divider 6 is connected with the rotating shaft 7 and the lid divider 6 is set below There is a rotating disk 4 for rotation. The rotating disk 4 is provided with a cover hole 5, and a mold is set inside, which can be die-casted.

[0013] The lid divider 6 has a cylindrical structure, and the material is an electromagnet for sucking the lid 2.

[0014] Six cover drop holes 5 are uniformly distributed on the rotating disk 4, and the rotating disk 4 is driven to rotate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com