Double-beam balance suspending frame

A technology of balancing suspension and balancing beam, applied in suspension, interconnection system, transportation and packaging, etc., can solve problems such as deformation damage, bearing force limitation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

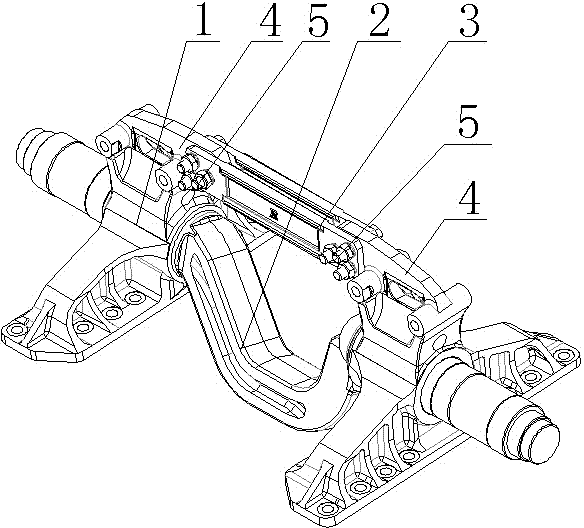

[0009] Such as figure 1 As shown, the double-beam balance suspension includes two bases 1 and a balance beam 2 installed on the bases. The middle of the balance beam is a "U"-shaped concave structure installed between the two bases. It is characterized by : it also includes a second balance beam 3, the second balance beam is cut from steel plate, with balance beam screw holes at both ends, an integral upward extension part 4 is arranged on the base, and the extension part The 4 side has the base screw hole that matches the balance beam screw hole, and the second balance beam is installed between the two bases through the balance beam screw hole and the base screw hole with the screw 5.

[0010] Further, the second balance beam 3 is composed of multiple steel plates.

[0011] The above descriptions are only specific embodiments of the present invention, but the structural features of the present invention are not limited thereto, and any changes or modifications made by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com