Soft magnetic ferrite core forming and blanking guide rail device

A soft ferrite and guide rail device technology, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of artificial order, waste of manpower, and difficulty in back-end production, so as to reduce the difficulty of employees' work. , The effect of improving product uniformity and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail:

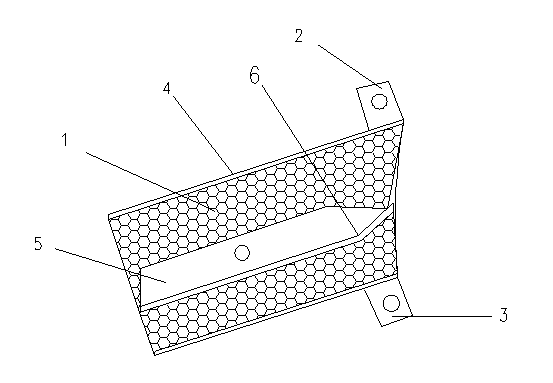

[0009] Such as figure 1 As shown, a soft ferrite magnetic core forming blank guide rail device includes a blanking plate 1, a left fixed part 2, a right fixed part 3, and a translation part 5, and is characterized in that: the blanking plate 1 is covered with holes type hollow, the two sides of the blanking plate 1 are provided with outer baffles 4, the blanking plate 1 is fixed on the press through 2 left fixed parts and 3 right fixed parts, and the blanking plate 1 is provided with a translation part 5, so The position of the translation component 5 in the blanking plate can be adjusted, and an inner baffle 6 is arranged on one side of the translation component 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com