Debugging method based on full-automatic battery-changing robot

A technology of a power exchange robot and a debugging method, applied in the field of robots, can solve the problems of large manual error, many calibration parameters, and long debugging cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

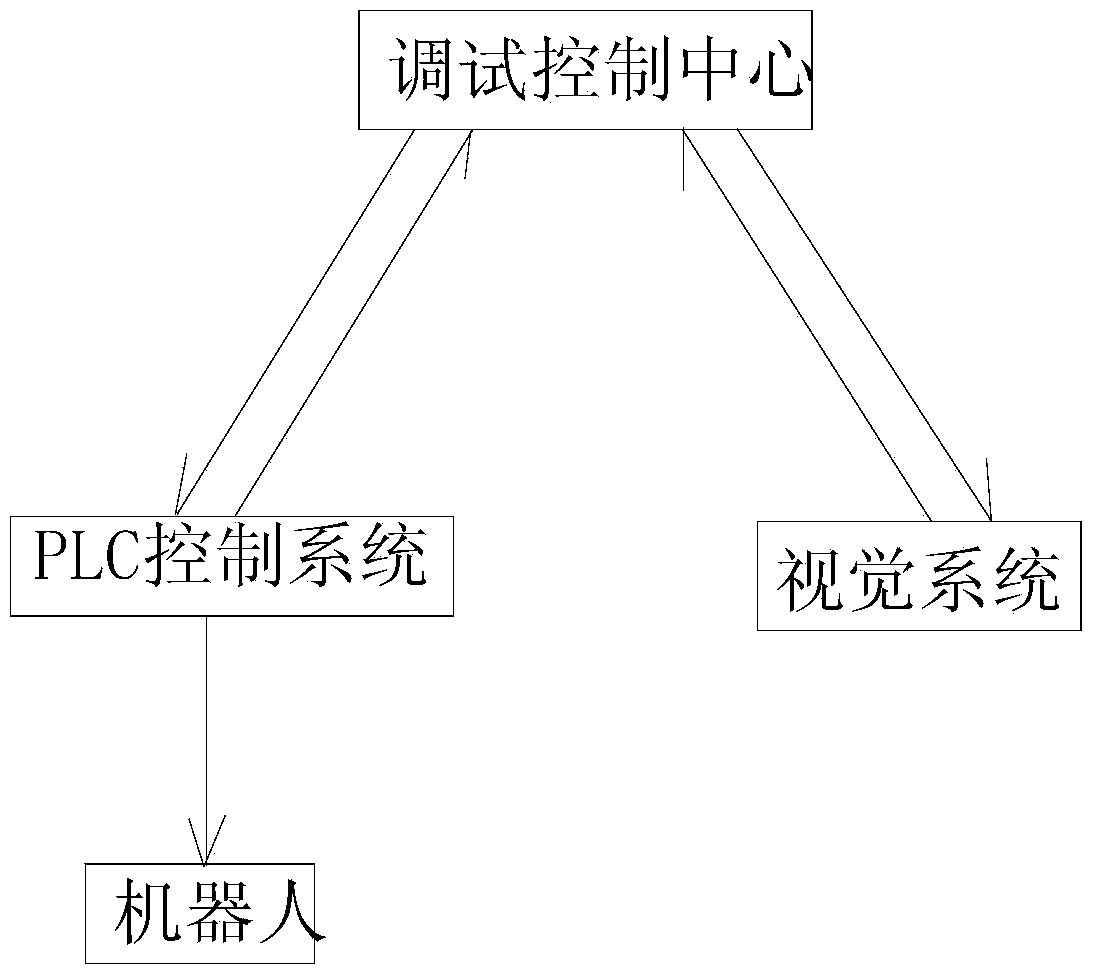

[0099] The present invention provides an automatic debugging method based on a fully automatic battery swapping robot, which includes the vision system function debugging of the battery swapping robot and a PLC controller in the face of the current situation of long debugging cycle, many calibration parameters and large manual errors in the existing debugging methods. The communication function debugging also includes the calibration of the battery box group coordinates and the calibration of the car battery pack pick-and-place coordinates.

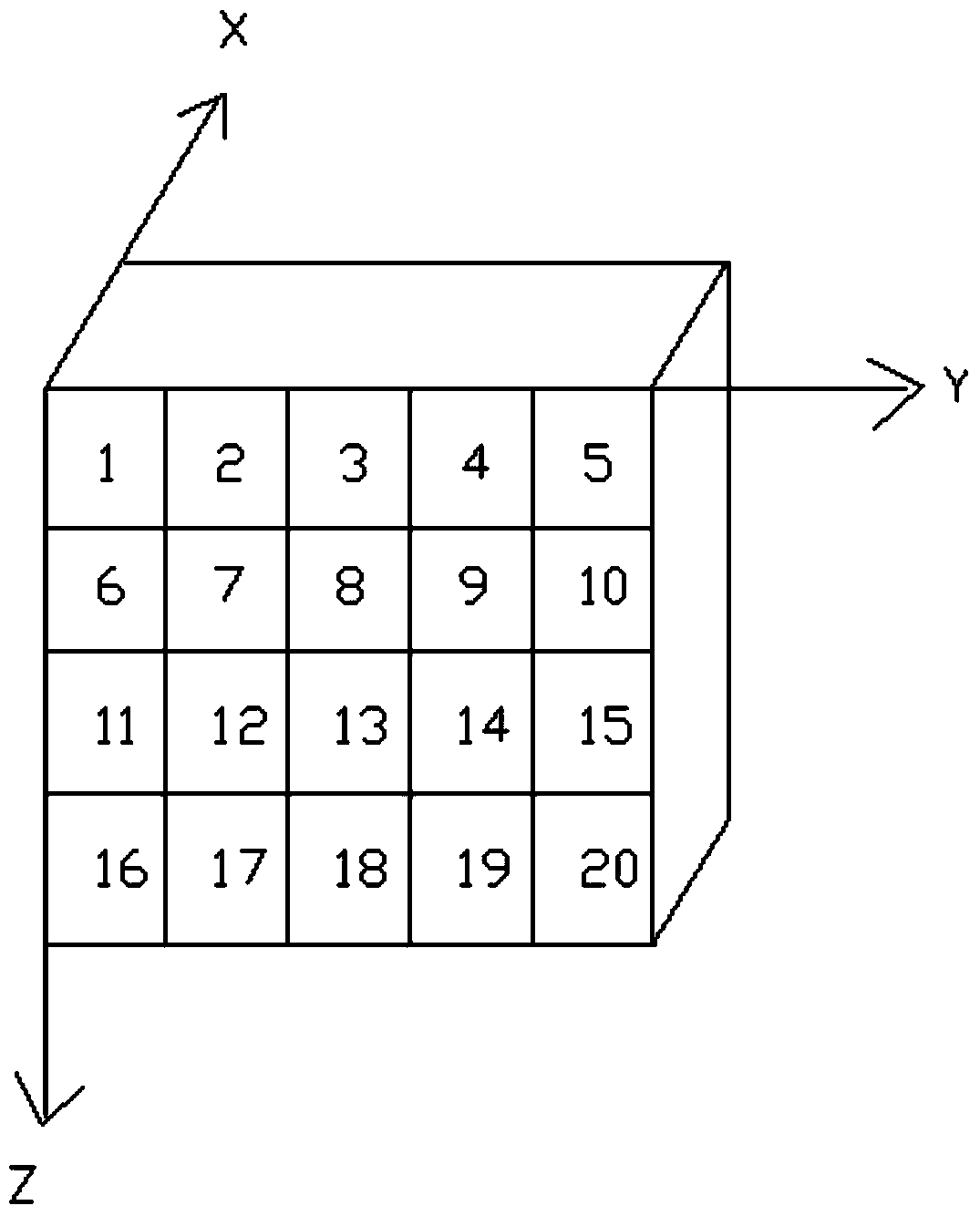

[0100] The vision system includes a top camera set above the electric vehicle for obtaining the position of the electric vehicle, and a side camera for obtaining the position of the battery to be replaced in the electric vehicle. The side camera is installed on the manipulator.

[0101] After the battery replacement robot is installed, use this method to complete the function debugging, coordinate calibration and debugging verification of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com