Probe cleaning method and probe cleaning device

A technology for cleaning devices and probes, applied in the field of probe cleaning and probe cleaning devices, can solve the problems that the accuracy and reliability of wafer test results need to be improved, and achieve the ability to prevent incomplete cleaning and remove impurities. , the effect of reducing cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the accuracy and authenticity of wafer testing in the prior art need to be improved.

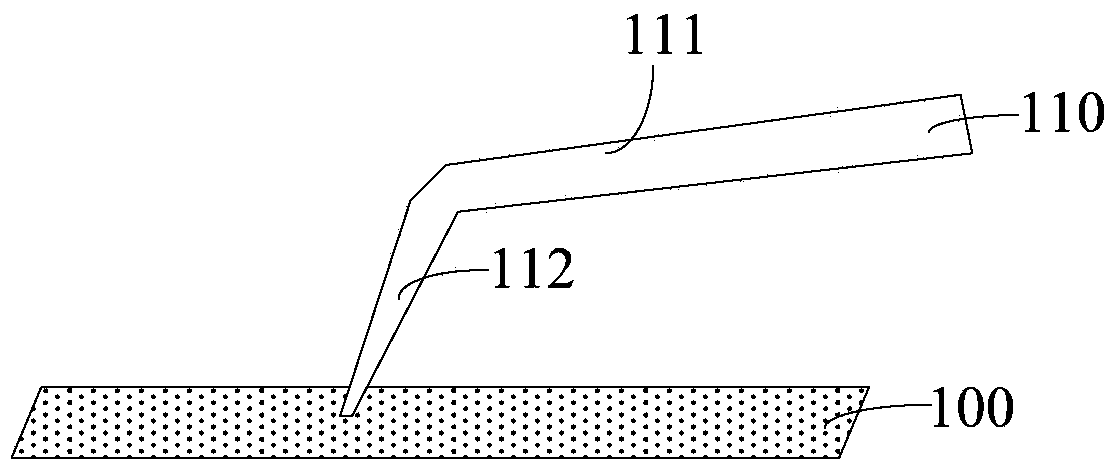

[0030] In order to solve the above problems, the analysis is carried out for wafer testing. Wafer testing has high accuracy in the electrical testing of the die, which is related to the production yield, cost and quality of the wafer. Because the surface of the tested die often forms an oxide film due to oxidation or pollution, or in order to avoid damage to the die to be tested, an isolation film is usually formed on the die for protection, and the isolation film is usually a poor conductor; If the isolation film at the die is not removed or is not removed cleanly during the test, the isolation film will hinder the contact and electrification effect between the probe and the wafer die to be tested, thereby affecting the accuracy and reliability of electrical testing.

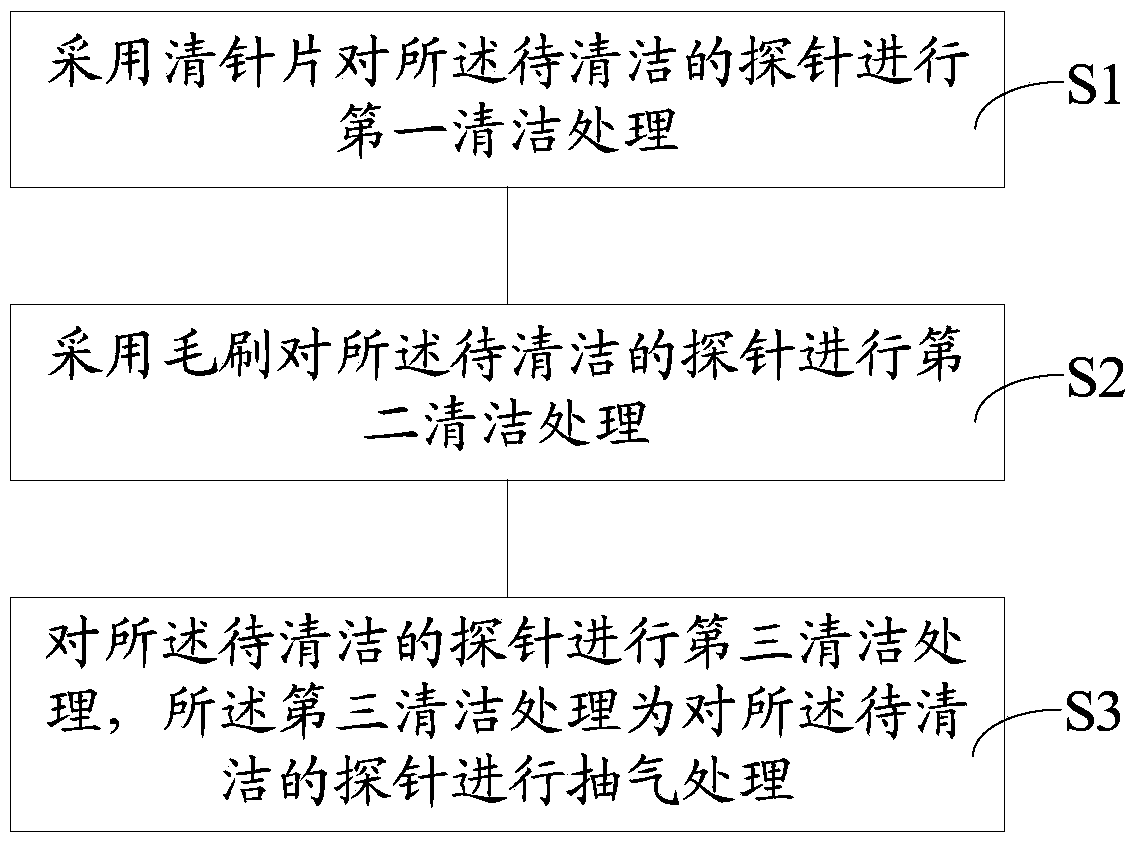

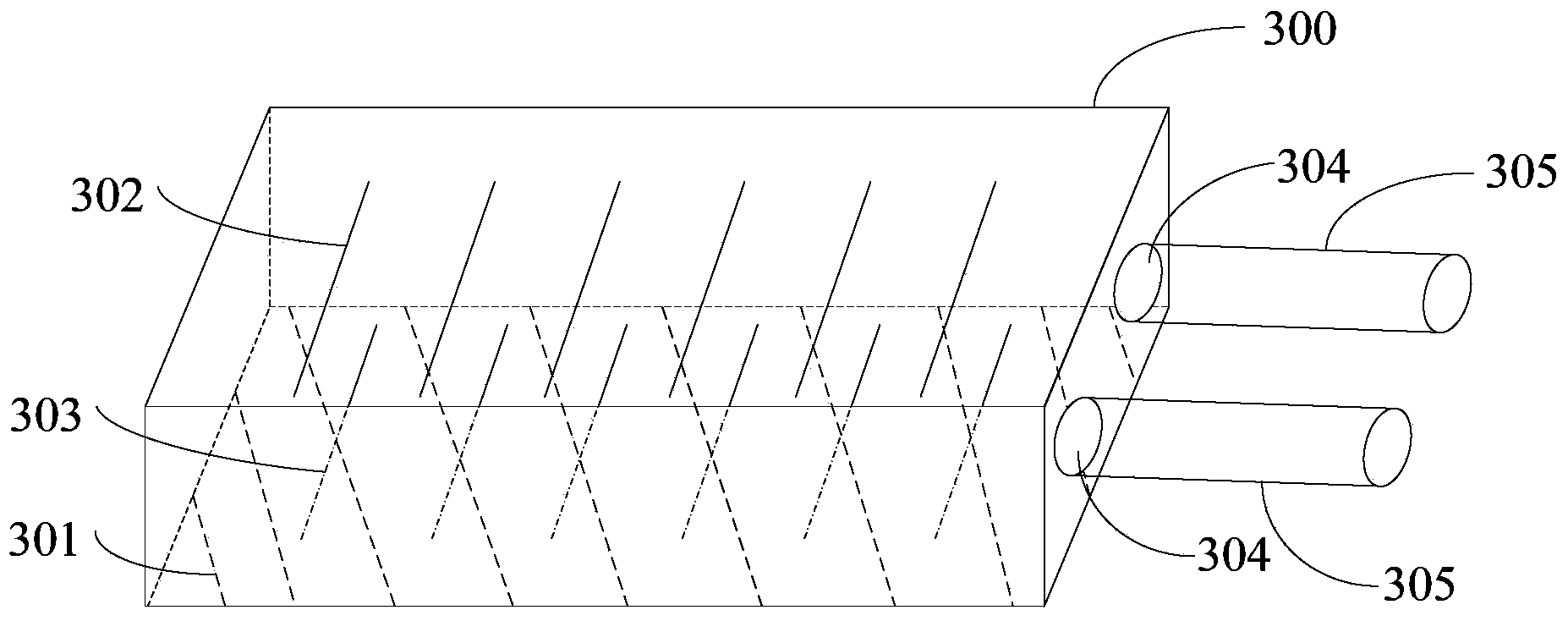

[0031] Therefore, when using a probe for electrical testing, a large co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com