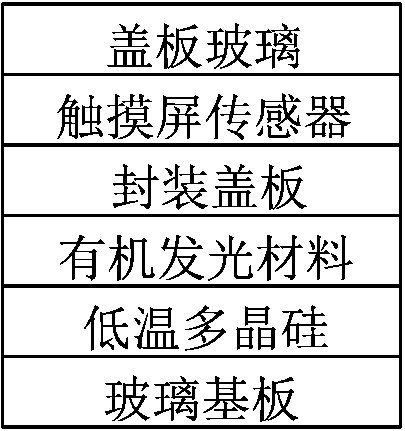

Method for manufacturing AMOLED display screen

A manufacturing method and display technology, applied in semiconductor/solid-state device manufacturing, data processing input/output process, instruments, etc., can solve the problems of complex manufacturing process, poor readability, thick display screen structure, etc. Low cost, simple and thin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following embodiments are designed according to the principles of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings and the following specific embodiments.

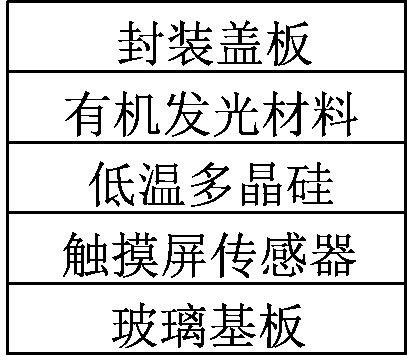

[0009] Such as figure 2 As shown, a touch-type AMOLED display in this embodiment includes a glass substrate, a low-temperature polysilicon layer covering the substrate, an organic light-emitting layer, and a packaging cover plate, and is characterized in that the glass substrate is arranged under the low-temperature polysilicon layer. There are touch screen sensors.

[0010] The specific process is: (1), making touch screen sensors on glass substrates; (2), making low-temperature polysilicon; (3), evaporating organic light-emitting materials; (4), packaging AMOLED devices; (5), AMOLED touch screen reduction Thin, packaging cover glass is reduced from 0.5mm to 0.3mm; (6), large AMOLED touch screen is cut into small cells; (7), small C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com