Capacitive touch panel

A capacitive touch and electrode technology, applied in the direction of electrical digital data processing, instruments, digital data processing components, etc., can solve the problem of large impedance, achieve low impedance, good signal transmission and sensing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the technical field of the present invention to further understand the present invention, several preferred embodiments and variant embodiments of the present invention are enumerated below, together with the accompanying drawings, to describe the composition of the present invention in detail.

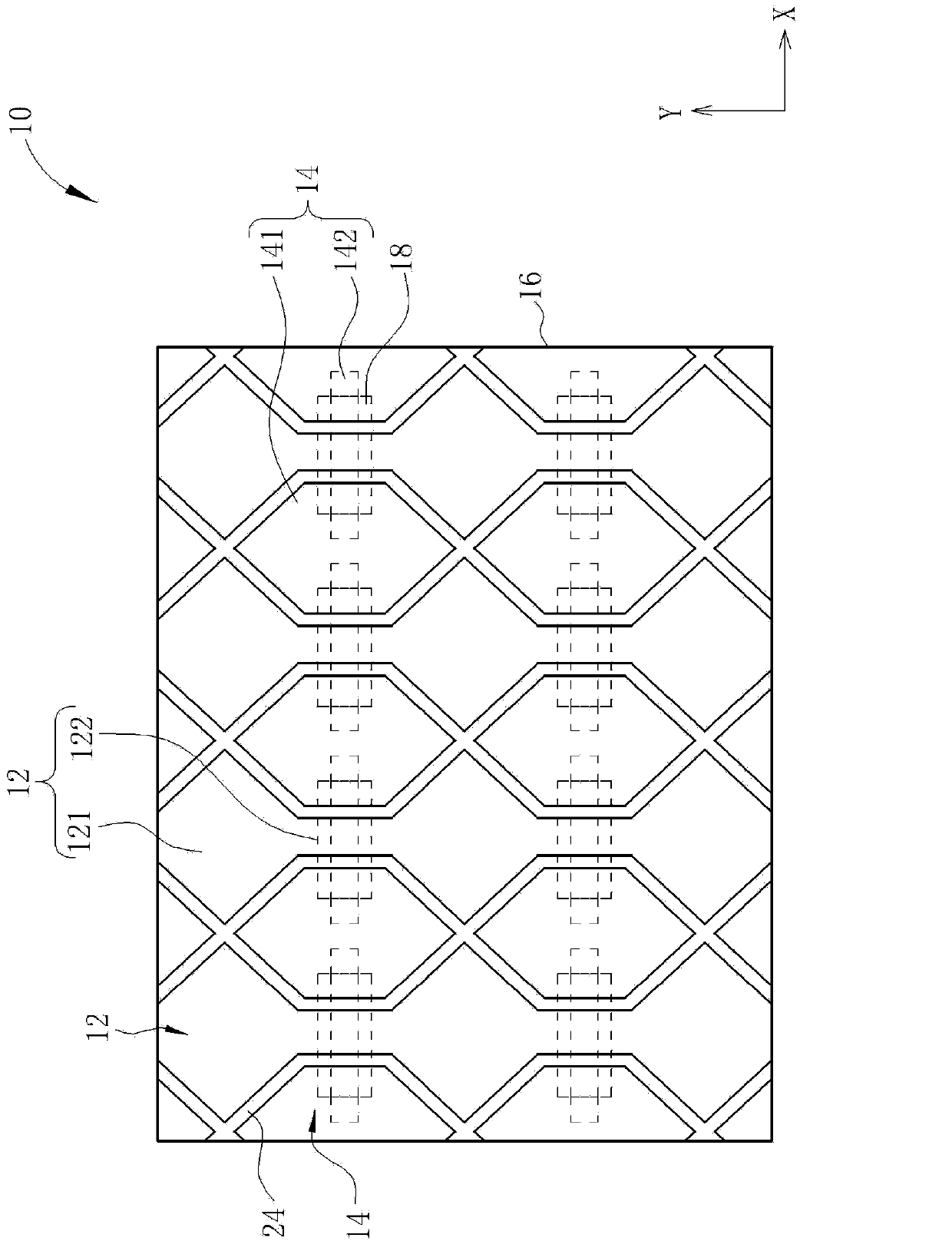

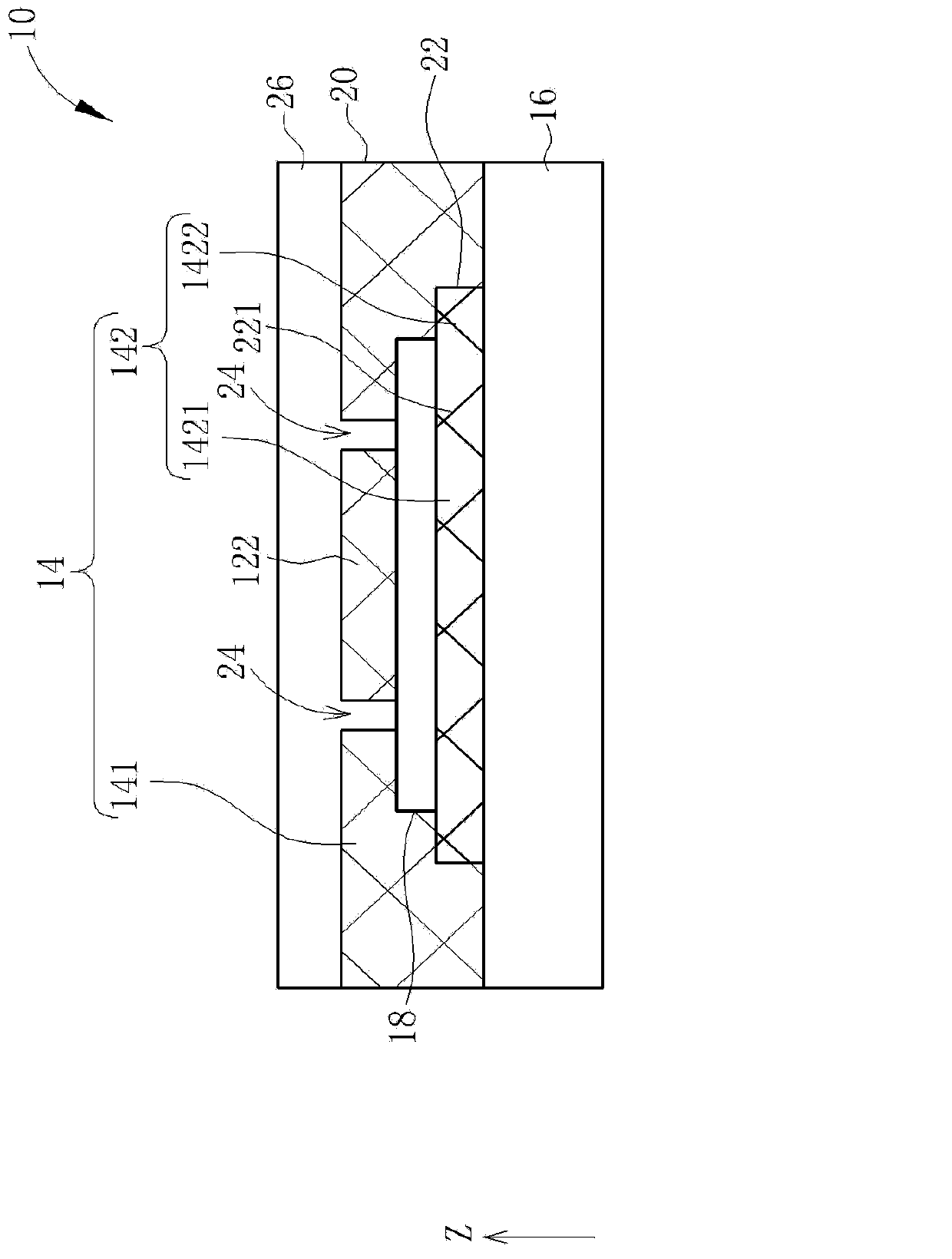

[0037] Please refer to figure 1 and figure 2 The capacitive touch panel 10 of the present invention includes a substrate 16 , at least one first electrode series 14 and at least one second electrode series 12 disposed on the surface of the substrate 16 . In this embodiment, the capacitive touch panel 10 includes a plurality of first electrode series 14 along the first direction ( figure 1 The X direction) is extended and arranged in multiple columns with a plurality of second electrode series 12 along the second direction ( figure 1 The Y direction) is extended and arranged in multiple columns, and the first direction intersects with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com