Belt conveyor automatic inspection system and method based on multi-rotor unmanned aerial vehicle

A multi-rotor unmanned aerial vehicle and belt conveyor technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of a large number of idlers, low detection accuracy, casualties, etc., to avoid Economic loss, avoidance of casualties, effects of broad applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

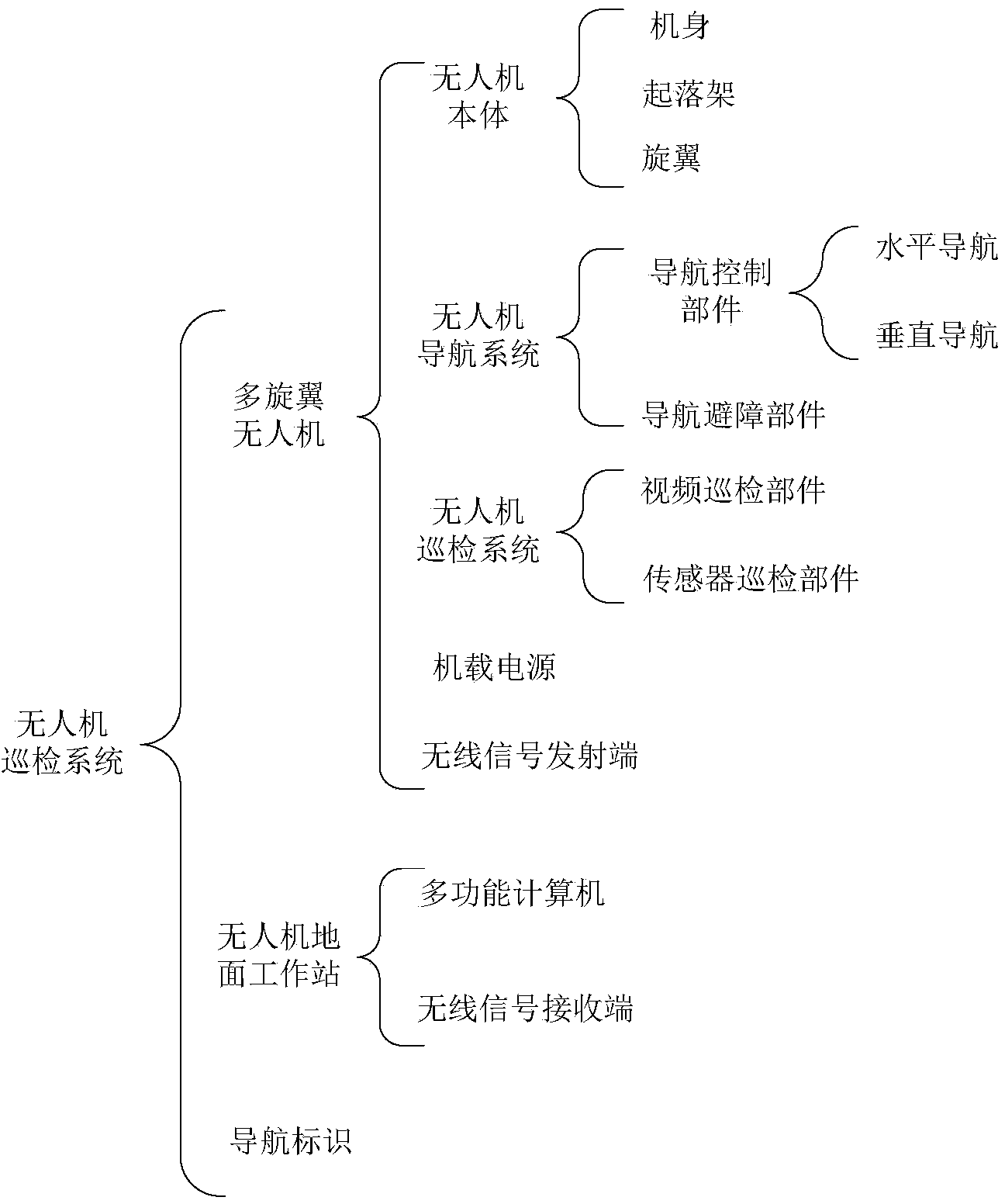

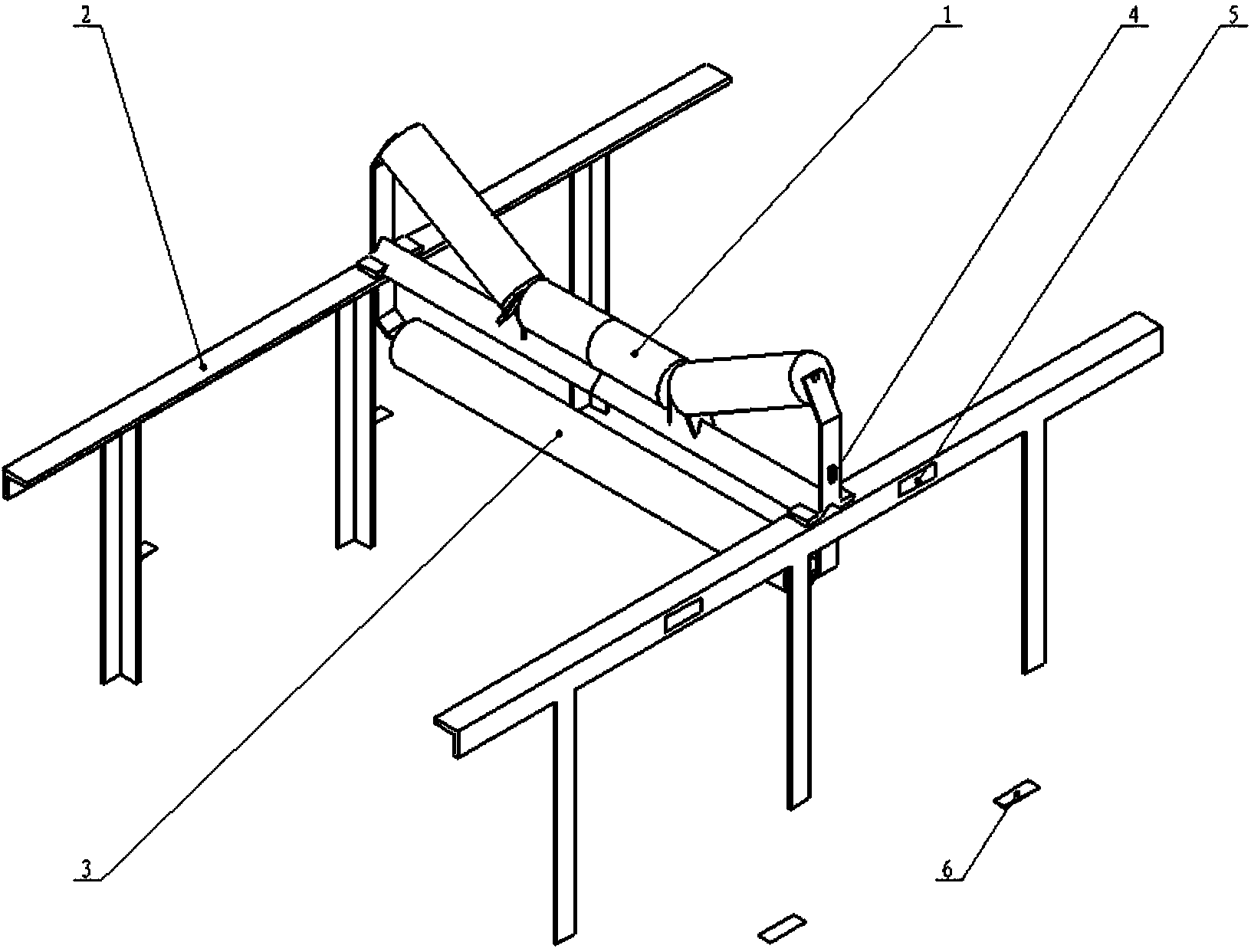

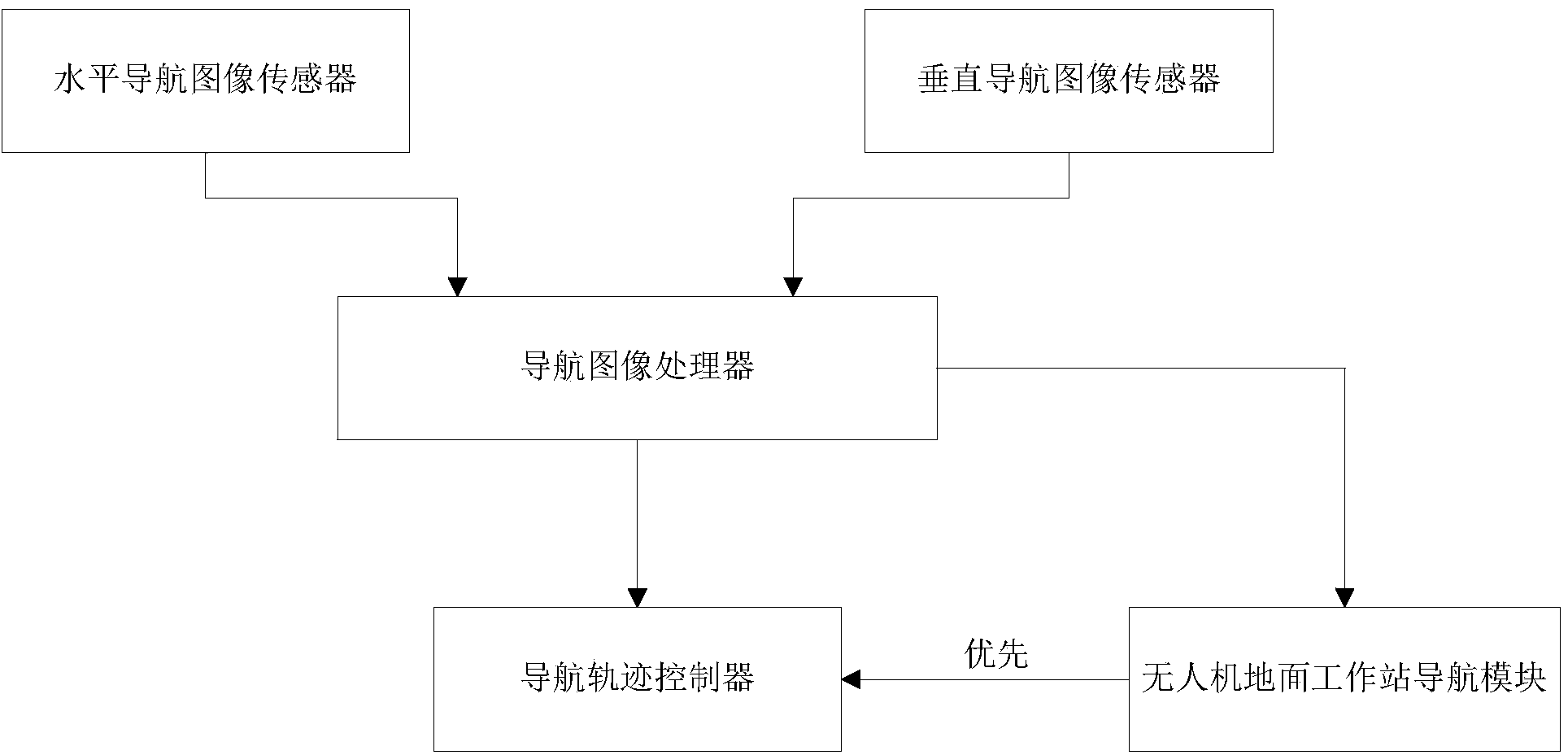

[0021] Example 1: In figure 1 Among them, the belt conveyor automatic inspection system based on the multi-rotor UAV of the present invention is suitable for real-time monitoring of the operating status of the belt conveyor. It mainly consists of multi-rotor drones, drone ground workstations and navigation signs. The multi-rotor drone includes the drone body, the drone navigation system, the drone inspection system, the onboard power supply and the wireless signal transmitter. The UAV body is composed of a fuselage, a landing gear fixed under the fuselage, and a plurality of rotors distributed in a symmetrical manner and installed around the fuselage. The UAV navigation system includes a flight navigation control part and a flight obstacle avoidance control part. The drone inspection system is composed of video inspection components and sensor inspection components. The onboard power supply contains a power management chip, which can manage the health of the power supply an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com